For decades, scientists have dreamed of creating wearable ultrasound devices that could image the body with the same clarity as hospital-grade machines—without bulky equipment or invasive procedures. Yet, a fundamental challenge has always stood in the way: flexibility. Conventional ultrasound sensors simply cannot bend and conform smoothly to the body’s complex curves without losing power and image quality.

Now, researchers at the Korea Advanced Institute of Science and Technology (KAIST) have taken a remarkable step toward solving this problem. A team led by Professor Hyunjoo Jenny Lee from the School of Electrical Engineering has developed a flexible ultrasound sensor that can change its shape and lock into position, allowing it to capture precise, body-conforming images.

Their invention, a “flex-to-rigid” capacitive micromachined ultrasonic transducer (CMUT), represents a breakthrough in the field of wearable medical technology. Published in npj Flexible Electronics, the research describes how this device can seamlessly switch between flexibility and rigidity, delivering both comfort and precision—something no previous design has achieved.

How the Shape-Shifting Sensor Works

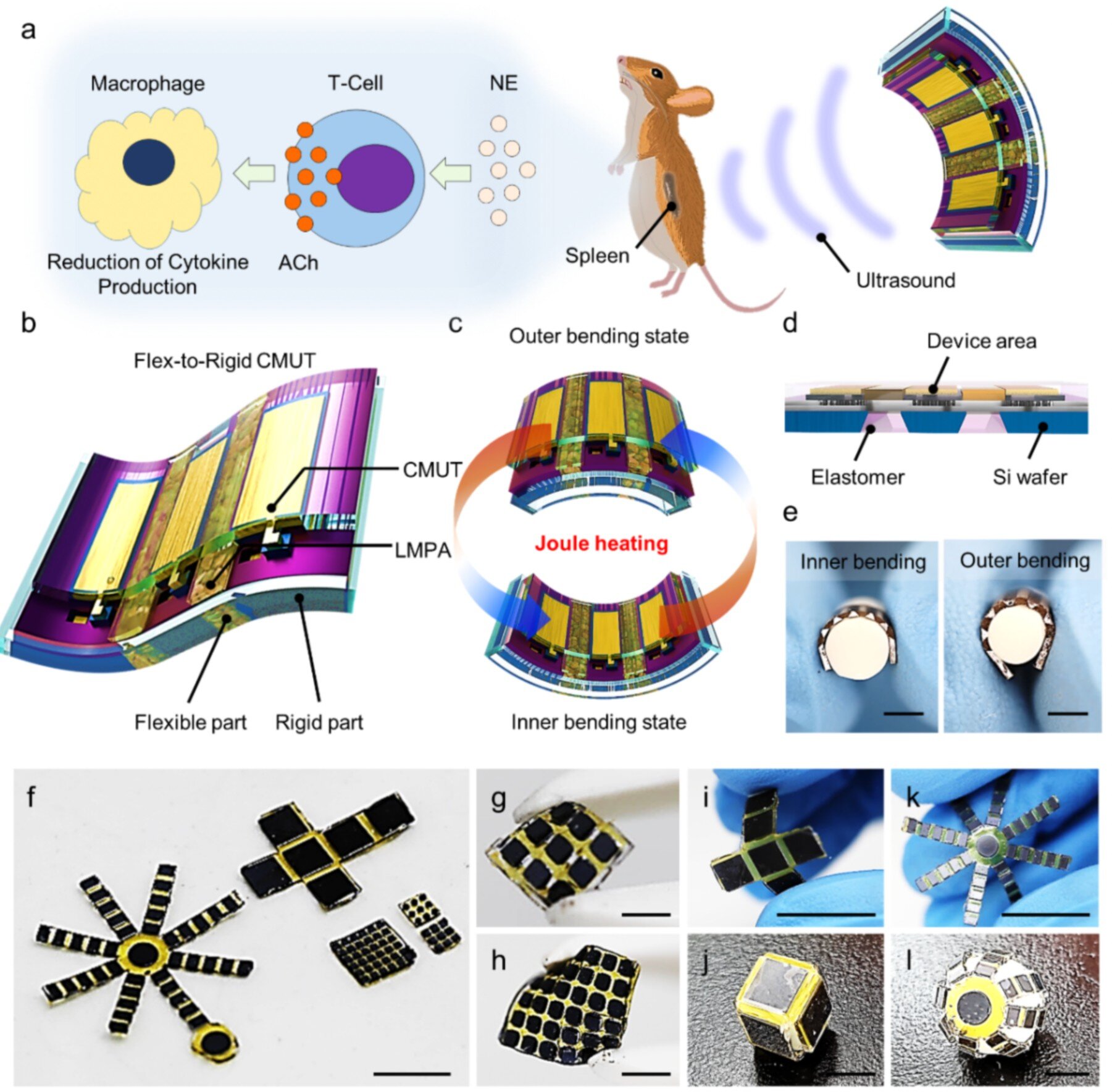

At the heart of the new device lies a simple but ingenious concept: control the sensor’s structure using heat and electricity. The team embedded a low-melting-point alloy (LMPA) inside the transducer’s body. When an electric current passes through, the alloy melts, making the device flexible enough to curve and adapt to the body’s surface. Once the current is turned off, the alloy cools and solidifies again, locking the device into its new shape.

This means that the sensor can conform to any part of the body—like wrapping gently around a wrist, neck, or joint—and then harden just enough to maintain a stable imaging surface. The result is a device that behaves almost like a living organism, shifting between soft and firm states as needed.

This “flex-to-rigid” transition, or FTR mechanism, is built using a semiconductor wafer process, also known as MEMS (microelectromechanical systems). This makes it not only scientifically sophisticated but also compatible with large-scale manufacturing—an essential feature for future medical applications.

Breaking the Barriers of Conventional Ultrasound

Traditional wearable ultrasound sensors rely on polymer membranes, which are soft and flexible but too weak to generate powerful, focused sound waves. This low elasticity leads to blurry imaging and limited depth, preventing their use in high-resolution diagnostics or precise therapy.

Professor Lee’s team overcame these issues by designing a hybrid structure: a rigid silicon substrate provides strong mechanical support, while a flexible elastomer bridge allows for bending and adaptation. The result is a sensor that offers both high acoustic power and mechanical flexibility—two qualities that usually conflict in ultrasound engineering.

Unlike standard devices that need complicated beamforming electronics to focus ultrasound waves, this sensor adjusts its focal point automatically by simply changing its curvature. When curved, it naturally concentrates sound waves on a specific target, producing sharper images or more precise energy delivery without extra components.

Equally impressive is its durability. Even after repeated bending and shape changes, the sensor retains stable performance—showing no signs of degradation in either its electrical or acoustic properties.

From Imaging to Therapy: A Dual Revolution

Beyond imaging, the new device also opens the door to noninvasive ultrasound therapy. Its output power reaches the level of low-intensity focused ultrasound (LIFU), a technology that can gently stimulate tissues to trigger biological effects without damaging cells.

In experiments on animal models, the KAIST team demonstrated that the device could stimulate the spleen noninvasively, reducing inflammation and improving mobility in arthritis-affected animals. This is a powerful demonstration of how ultrasound energy, when delivered precisely and safely, can influence biological processes to promote healing.

Such therapeutic potential could be transformative. Imagine a lightweight patch that reduces inflammation in injured muscles, relieves chronic pain, or improves blood circulation—without injections, pills, or surgery. With this technology, that vision is no longer science fiction.

Toward Smarter, Wearable Medical Systems

Professor Lee’s team is now working on the next phase: transforming the single flexible transducer into a two-dimensional array—a grid of multiple sensors that can work together to capture high-resolution images while simultaneously providing localized therapy.

This advancement would mark the beginning of multi-functional, wearable ultrasound systems capable of real-time imaging, diagnostics, and treatment—all integrated into a single, skin-friendly device.

Because the technology is built on standard semiconductor fabrication techniques, it can be mass-produced efficiently, reducing costs and accelerating adoption. This compatibility also makes it easy to integrate with other electronic components, such as wireless communication modules, biosensors, or AI-driven imaging software.

The future might see these sensors embedded in wearable patches, smart clothing, or portable medical kits—turning everyday healthcare into a continuous, personalized process.

The People Behind the Breakthrough

This study was led by Professor Hyunjoo Jenny Lee, a pioneer in the intersection of electronics and biomedical engineering. The research team included Sang-Mok Lee and Xiaojia Liang as co–first authors, alongside several collaborators. Their shared vision was to bridge the gap between human biology and advanced materials science—to make medical devices that are not only intelligent but also physically adaptable to the human form.

Their success with the flex-to-rigid CMUT is more than a technical achievement—it’s a conceptual leap. It demonstrates that electronic devices can now behave more like living tissues, dynamically changing shape and function to meet the body’s needs.

A Glimpse Into the Future of Noninvasive Medicine

The implications of this innovation stretch far beyond ultrasound. By combining mechanical flexibility, electrical control, and biological compatibility, the KAIST team’s approach could inspire a new class of shape-adaptive biomedical devices.

Such devices might one day monitor internal organs continuously, deliver targeted therapies deep within the body, or provide precise imaging for early disease detection—all while remaining comfortable enough to wear daily.

As medicine continues to move toward personalization and prevention, technologies like this flexible ultrasound sensor could redefine what it means to “visit the doctor.” Instead of occasional checkups, people could have continuous insight into their health, guided by sensors that think, move, and heal alongside the body.

The Shape of Things to Come

The invention of a shape-shifting ultrasound sensor is not just an engineering feat—it’s a glimpse into the next era of healthcare. It represents the merging of human adaptability with technological precision.

From the quiet hum of a flexible circuit to the gentle pulse of ultrasound waves stimulating healing deep within the body, this breakthrough marks a turning point in how we think about medical devices.

Thanks to innovations like the flex-to-rigid CMUT, the future of medicine may not lie in the hospital at all—but in the seamless integration of technology with the human body, where healing and monitoring happen naturally, effortlessly, and continuously.

More information: Sang-Mok Lee et al, Flexible ultrasound transducer array with statically adjustable curvature for anti-inflammatory treatment, npj Flexible Electronics (2025). DOI: 10.1038/s41528-025-00484-7