Imagine a material that can stretch nearly fifty times its length without snapping, that glows in different colors when pulled, and that, even if torn apart, can heal itself within minutes. It sounds like something out of science fiction, yet scientists in Taiwan have turned this vision into reality.

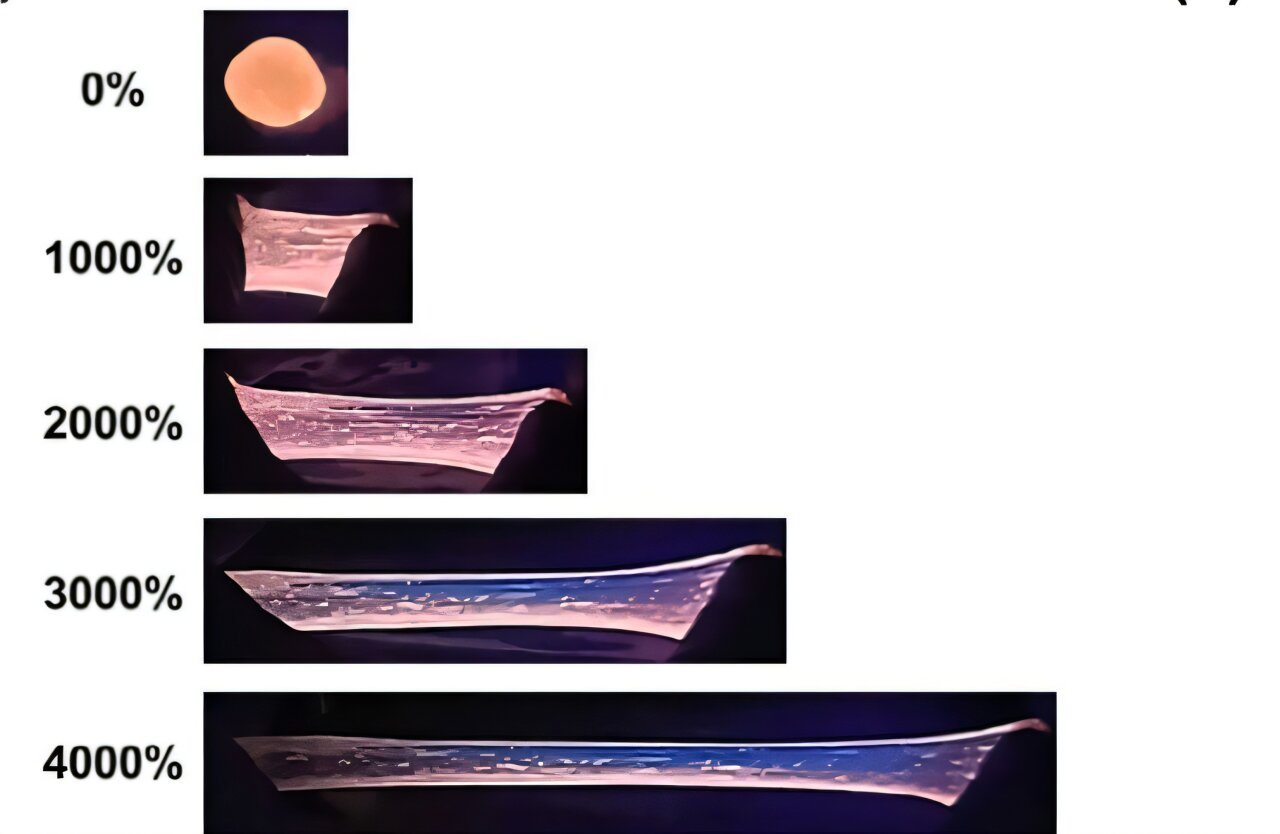

Their breakthrough—a polyurethane (PU) organogel capable of stretching up to 4,600% of its original length—represents a revolution in how we might design materials for the future. More than just tough, this gel is also intelligent: it repairs itself, senses mechanical forces, and even changes color depending on how much stress it is under. These properties could one day transform industries ranging from robotics to healthcare, electronics to security.

The study, published in Advanced Functional Materials, shows how blending creativity at the molecular level with cutting-edge polymer science can lead to extraordinary innovations.

The Challenge of Building Resilient, Intelligent Materials

For decades, scientists have sought to design materials that mimic the adaptability of living tissue. Human skin, for instance, stretches easily, repairs itself when cut, and signals damage through pain or discoloration. Most synthetic materials, however, are rigid and unforgiving. Plastics crack, fabrics tear, and electronic components degrade over time.

Creating materials that combine durability, flexibility, self-repair, and sensory abilities is one of the great challenges of materials science. Success would mean devices and products that last longer, waste less, and respond intelligently to their environment.

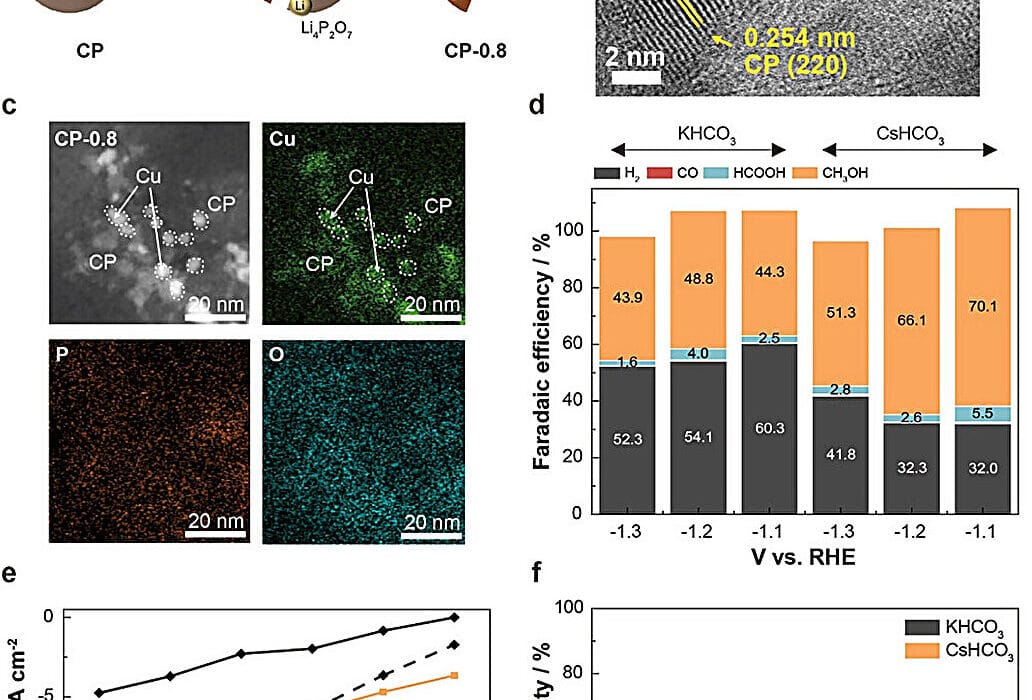

The Taiwanese research team approached this challenge by bringing together two powerful molecular strategies: mechanically interlocked molecules (MIMs) and cellulose nanocrystals (CNCs).

Molecular Muscles: How MIMs Power the Gel

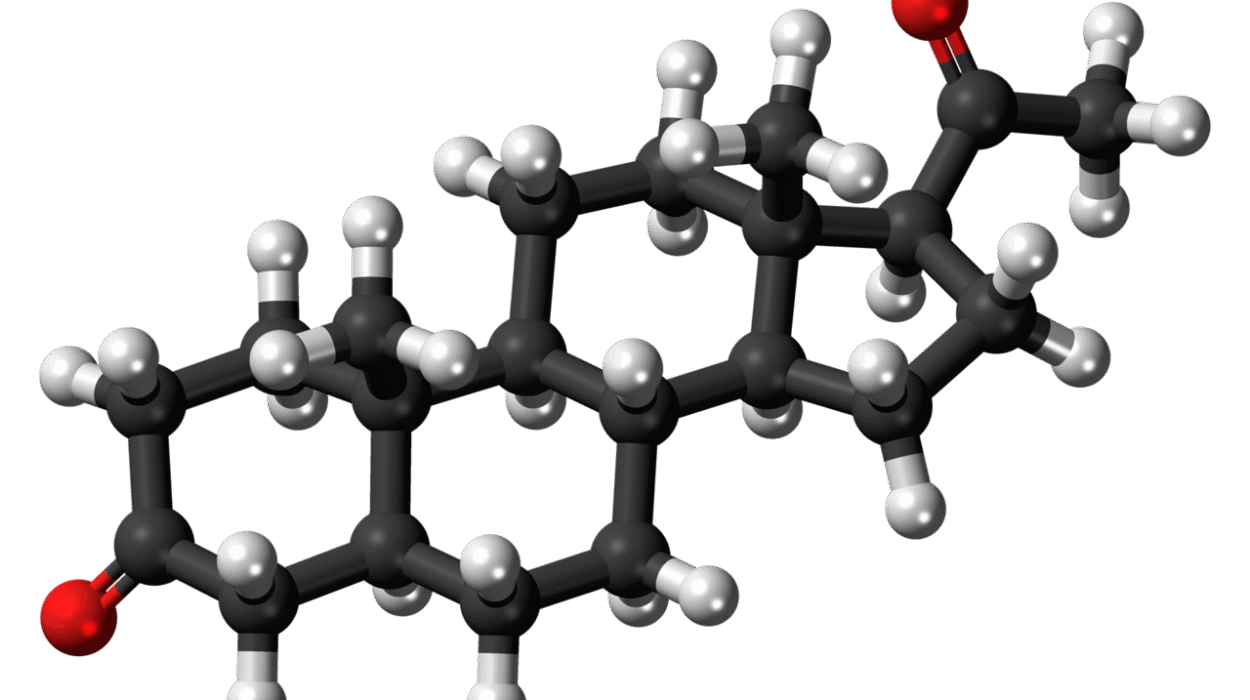

Mechanically interlocked molecules, or MIMs, are special molecular structures where two or more components are linked not by chemical bonds but by mechanical entanglement—like beads on a thread or loops on a chain. Famous examples include rotaxanes and daisy chains, both of which can slide or rotate in response to external forces.

In this new gel, MIMs act like molecular muscles. When the gel is stretched, the interlocked molecules shift and rearrange, absorbing stress and preventing the material from breaking. This gives the gel extraordinary toughness and elasticity.

But the magic doesn’t stop there. MIMs also carry mechanophores—tiny molecular switches that respond to mechanical forces. When stretched, they undergo subtle structural changes that alter how they interact with light. This is why the gel changes color: from a warm orange glow at rest to a cool blue fluorescence when under tension.

It’s as though the material has its own language, speaking through light to reveal its hidden state.

The Role of Cellulose: Nature Meets Innovation

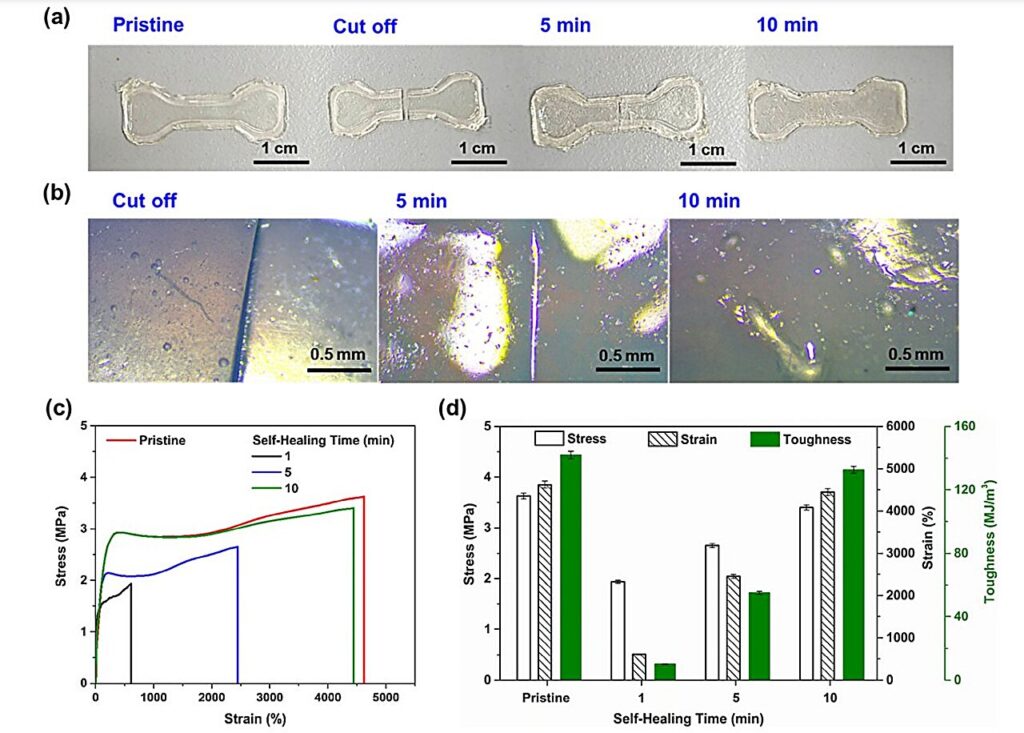

While MIMs provide movement and toughness, cellulose nanocrystals (CNCs) add another crucial feature: self-healing. Derived from plant matter, CNCs form strong hydrogen bonds within the polymer structure. These bonds can break and reform easily, enabling torn pieces of the gel to “find” each other again.

When the material is damaged, gently pressing the broken parts together at room temperature allows the CNCs to re-establish their network. Within 10 minutes, the gel recovers more than 90% of its original strength and stretchability. No heat, no glue—just molecular teamwork at its finest.

This combination of high-tech synthetic design with renewable natural components also points to a sustainable path forward. Instead of relying solely on petroleum-based polymers, scientists are finding ways to harness nature’s chemistry to make smarter, greener materials.

A Color-Changing Symphony

One of the most dazzling features of this material is its mechanochromic behavior—its ability to change color in response to mechanical stress.

The research team modified their MIMs with fluorescent groups known as DPAC units. When the gel is relaxed, DPAC units vibrate freely, emitting orange light at 603 nanometers. But when the gel is stretched, these units are forced into constrained positions, shifting their emission to a bright blue at 451 nanometers.

This visible transformation is more than just a party trick. It means the gel can act as a built-in stress sensor, instantly signaling when it is under strain or damaged. In applications like wearable electronics, soft robotics, or even infrastructure, such a feature could provide real-time feedback and prevent failures before they occur.

Strength in Numbers: Extraordinary Performance

The team’s optimized gel contained only about 1.5 wt.% of MIMs, yet the results were staggering. The material demonstrated a toughness of 142 MJ/m³—a measure of how much energy it can absorb before breaking—and could stretch 46 times its original size.

Equally impressive was its ability to recover after damage. Whether cut, torn, or punctured, the gel could autonomously heal itself, regaining both its flexibility and fluorescence. This level of performance suggests a future where materials need far less replacement, reducing waste and improving safety.

A World of Applications

The implications of this discovery are immense. Here are just a few of the potential applications that researchers and engineers are already envisioning:

- Flexible electronic skins: The gel’s self-healing and color-changing features make it ideal for use in artificial skin for robots or prosthetics, where it could both stretch naturally and detect damage.

- Soft robotics: Robots made from soft, adaptable materials could move more fluidly and repair themselves if damaged, extending their operational lifetimes.

- Anti-counterfeiting technologies: The gel’s unique fluorescence could serve as a security feature, difficult to replicate and easy to verify.

- Wearable devices: From smart clothing to medical sensors, the gel could provide both comfort and resilience.

- Sustainable technologies: By extending product lifetimes and signaling when repairs are needed, this material could reduce waste and environmental impact.

Bridging Science and Imagination

What makes this breakthrough so remarkable is how it blurs the line between biology and technology. Materials like this gel behave almost like living systems—they sense, respond, and heal. They invite us to rethink what synthetic matter can do.

For centuries, human-made materials have been rigid, lifeless, and disposable. This new gel suggests a different future: one where our technologies are flexible, adaptive, and enduring. A future where materials can be repaired instead of discarded, where color changes warn us of stress, and where the distinction between the living and non-living becomes less clear.

Looking Ahead

Of course, challenges remain. Scaling this material for mass production will require cost-effective synthesis methods and careful testing under real-world conditions. Engineers will need to ensure it performs reliably in complex environments, from electronic circuits to outdoor weathering.

Yet the foundations are now in place. By merging molecular ingenuity with natural chemistry, scientists have created a platform that could reshape entire industries.

Conclusion: A Material That Heals and Speaks

The Taiwanese team’s PU organogels are more than just stretchy and sticky—they are a preview of a new generation of materials. These gels can stretch impossibly far, heal themselves almost instantly, and communicate their state through brilliant colors. They are tough, adaptable, and sustainable, embodying qualities once reserved for the living world.

If scaled successfully, this discovery could usher in a new era where our materials are no longer passive tools but active partners—self-repairing, responsive, and enduring. It is a glimpse of a future where our built environment becomes as dynamic and resilient as life itself.

Physics, chemistry, and imagination have converged to create something extraordinary: a material that not only survives stress but learns to thrive within it.

More information: Tu Thi Kim Cuc et al, Effective Sliding Motions of Vibration‐Induced Emission Stoppers in Mechanically Interlocked Molecules as Artificial Muscle Tougheners and In Situ Molecular Shuttling Sensors for Self‐Healable Mechano‐Fluorescent Polyurethane Organogels, Advanced Functional Materials (2025). DOI: 10.1002/adfm.202519737