Heterogeneous catalysts have been a cornerstone of industrial chemistry, accelerating chemical reactions by providing a different phase or state than the reactants involved. Their unique ability to remain stable and efficient even under extreme conditions, such as high pressure and temperature, has made them indispensable in fields ranging from petrochemicals to agriculture. Traditionally, metals like iron, platinum, and palladium have served as the go-to catalysts for vital reactions, such as the hydrogenation of organic compounds and the Haber process for ammonia synthesis. However, the high cost and limited availability of these metals have sparked growing interest in finding more sustainable alternatives. Moreover, issues such as coking, where carbon deposits accumulate on the catalyst surface, limit the efficiency and longevity of these precious metal catalysts. As the push for more cost-effective and eco-friendly solutions increases, scientists have increasingly turned to more abundant elements and innovative approaches to catalyst design.

One of the most transformative developments in catalysis occurred in the mid-2000s, when researchers introduced the concept of Frustrated Lewis Pairs (FLPs). This concept marked a breakthrough in small molecule activation, particularly in reactions involving stable but hard-to-break molecules such as hydrogen, carbon dioxide (CO₂), and ammonia (NH₃).

Frustrated Lewis Pairs: Unlocking New Possibilities for Catalysis

An FLP is created by pairing a Lewis acid with a Lewis base, both of which are highly reactive. However, unlike traditional acid-base pairs, FLPs cannot fully interact with each other due to spatial or electronic hindrance, resulting in a “frustrated” interaction. This frustration leaves both sites in a highly reactive state, which is key to their catalytic properties. FLPs offer a remarkable advantage over traditional catalysts by having multiple active sites, making them more reactive and selective. In contrast, most conventional catalysts typically feature only one active site, limiting their ability to perform efficiently across a wide range of reactions.

FLPs are divided into two broad categories: heterogeneous defect-regulated FLPs and molecular-based homogeneous FLPs.

1. Heterogeneous FLPs: Controlling Reactivity through Surface Defects

In the case of heterogeneous defect-regulated FLPs, the number and arrangement of active sites are controlled by the presence of surface defects in solid materials. While this strategy has proven effective, one of the challenges in utilizing heterogeneous FLPs is accurately tuning their reactivity and ensuring long-term stability. Fine-tuning the surface defect structures can be a complex and tedious process, making this method less accessible for broader industrial use.

2. Molecular-Based Homogeneous FLPs: Flexible and Adjustable Catalysts

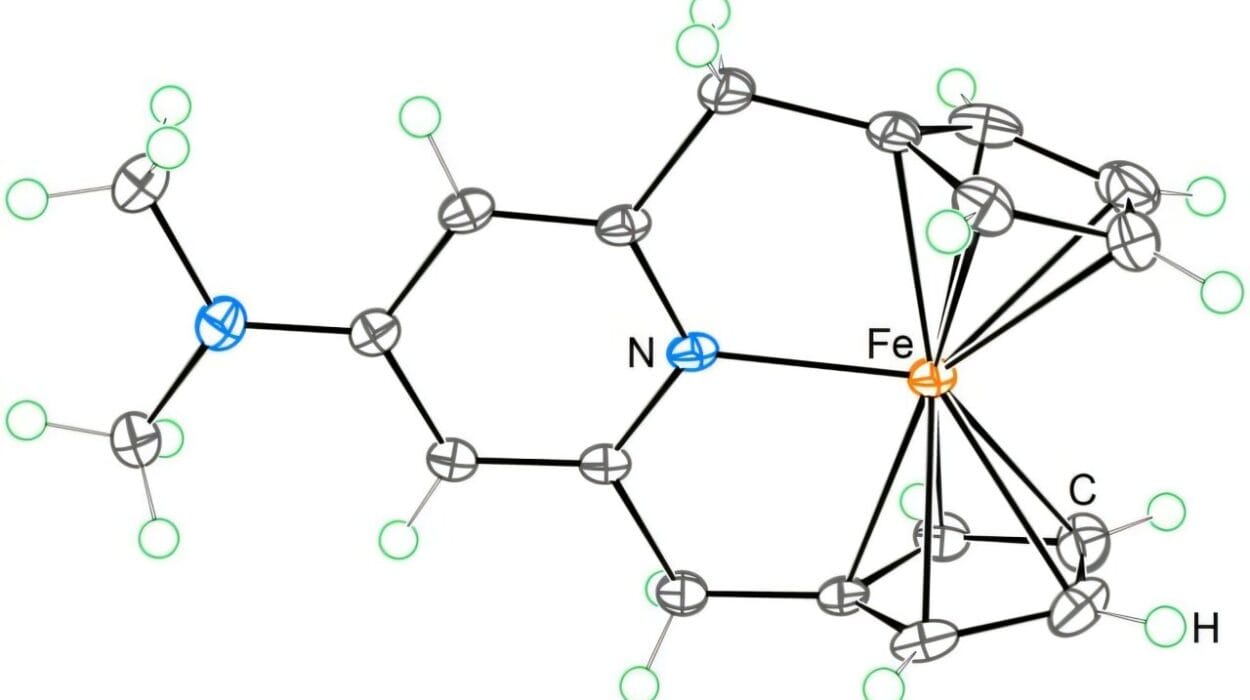

On the other hand, molecular-based homogeneous FLPs offer a simpler method for controlling reactivity. In these systems, the Lewis acid and Lewis base exist within the same molecular structure, which makes it easier to fine-tune the FLP’s reactivity by altering the surrounding molecular components. This flexibility is particularly useful in designing single-site catalysts that can be adapted for a variety of industrial processes, including hydrogenation, hydroformylation, and CO₂ activation.

Solid-State FLPs: The Next Frontier in Catalysis

In the pursuit of improving the reactivity and stability of FLPs for industrial-scale applications, a novel approach has emerged: adapting molecular-based FLPs for solid-state systems. This cutting-edge innovation aims to bring the advantages of FLP catalysis to heterogeneous materials that can withstand even the harshest conditions, such as elevated temperatures and aggressive chemical environments.

In November 2024, a groundbreaking study was published in Angewandte Chemie International Edition, offering new insights into the development of a solid-state FLP made using polymer-derived ceramics. The study, led by Professor Yuji Iwamoto from the Nagoya Institute of Technology (Japan), Dr. Samuel Bernard from the University of Limoges (France), and Professor Ravi Kumar from the Indian Institute of Technology Madras (India), presented a method for tailoring molecular-based FLPs to operate in solid-state systems, making them suitable for high-temperature, high-pressure reactions.

The Role of Polymer-Derived Ceramics: Creating a Versatile Solid-State Catalyst

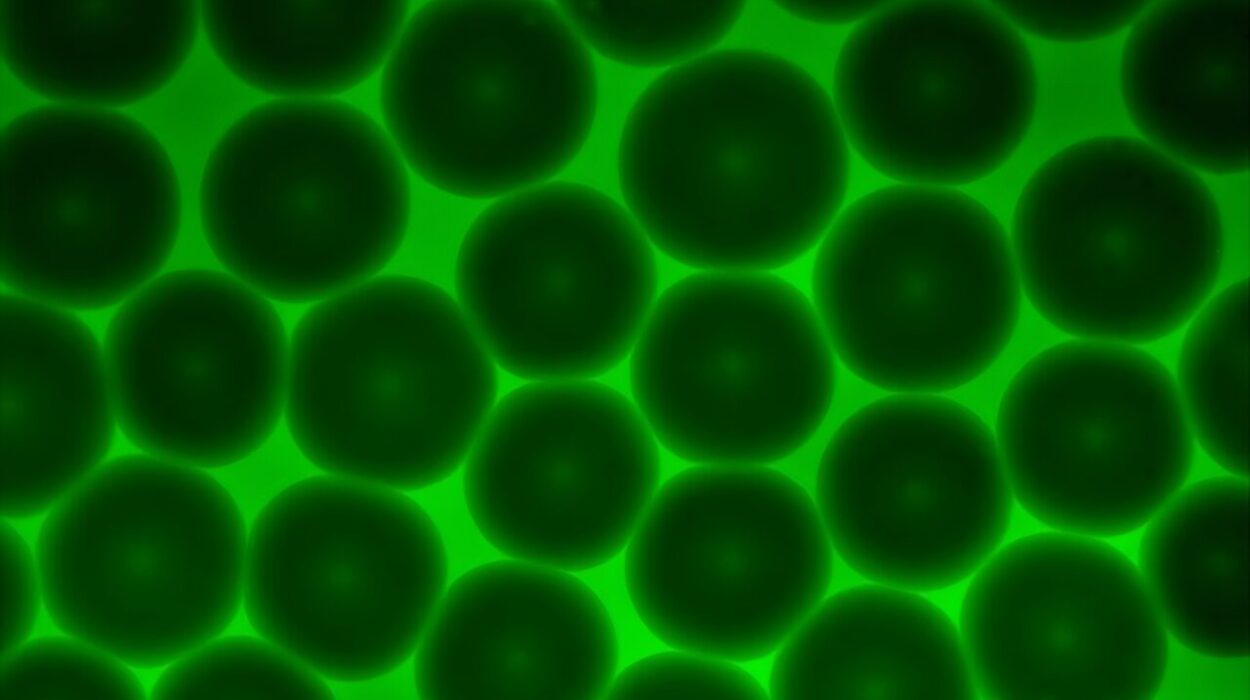

To achieve this novel development, the research team turned to pre-ceramic polymers, specifically polysilazane, which is rich in nitrogen and can form an amorphous silicon nitride (a-SiN) matrix when converted through a thermochemical process. By chemically modifying polysilazane with boron and sodium—both abundant and less toxic than many metals—they created a solid-state material that contains active sites with both Lewis acid (boron) and Lewis base (nitrogen) properties.

This solid-state material, referred to as sodium-doped amorphous silicon-boron-nitride (Na-doped SiBN), was exposed to flowing ammonia at a temperature of 1000 °C. The resulting material demonstrated exceptional properties, including high thermal stability and robust catalytic performance under extreme conditions.

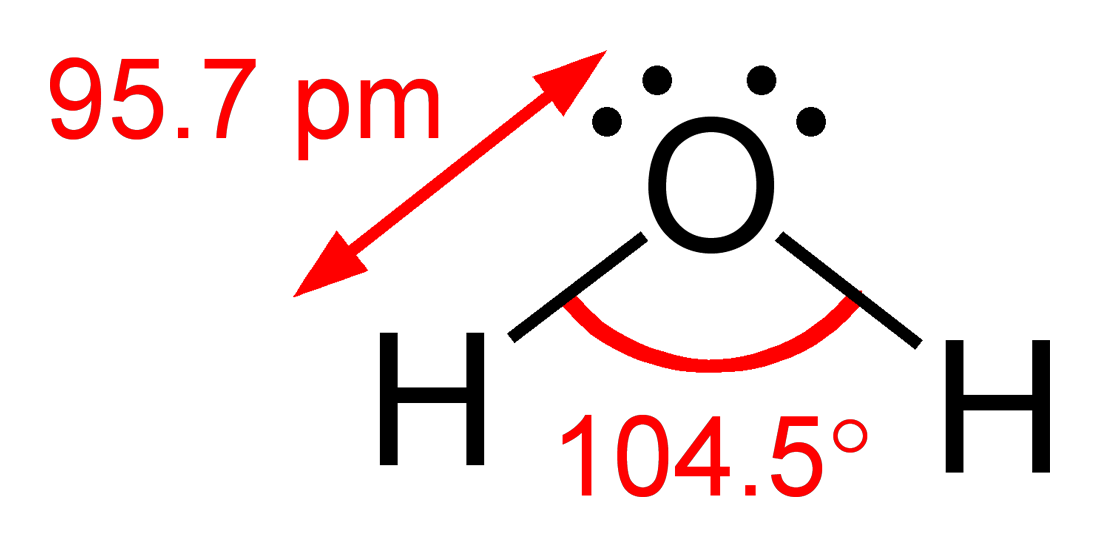

Reactivity at the Molecular Level: How Na-Doped SiBN Interacts with Hydrogen

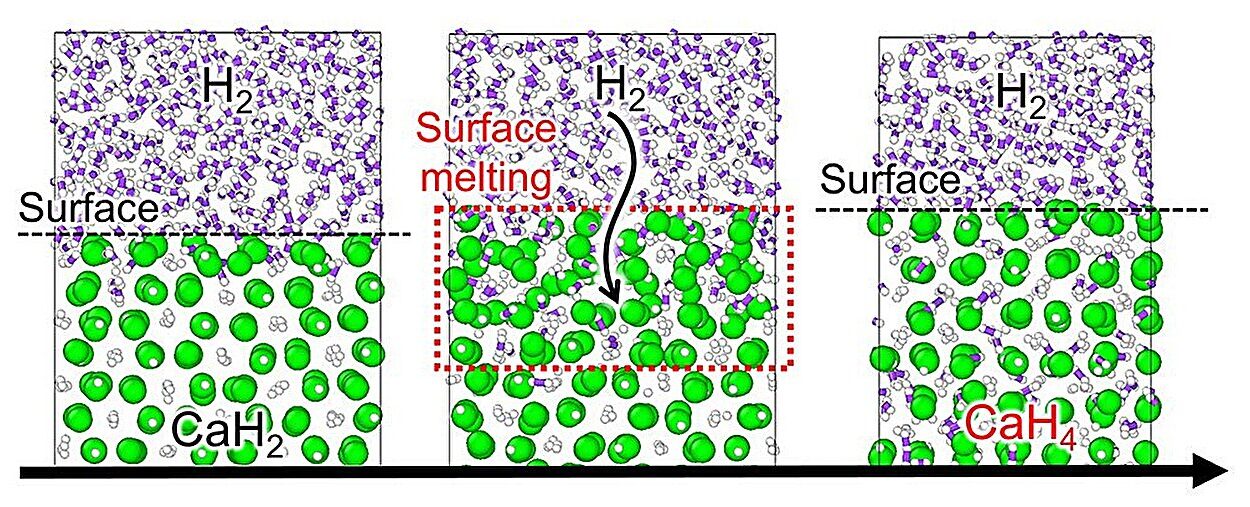

One of the key breakthroughs of this study was the use of advanced spectroscopic techniques to explore how the Na-doped SiBN material interacted with hydrogen molecules. When hydrogen was introduced, it interacted with both the boron sites and the sodium ions, leading to the formation of a frustrated Lewis acid (FLA) site.

This interaction caused a transition from a 3-fold-coordinated boron-nitrogen structure to a more distorted, polar structure with 4-fold coordination—an essential step for creating FLP activity. The changes to the nitrogen-hydrogen (N-H) bonds triggered the formation of frustrated Lewis base (FLB) sites. These dynamic interactions enabled the material to reversibly adsorb and desorb hydrogen, a critical feature for hydrogenation reactions.

Through thermodynamic experiments, the researchers confirmed that the material could efficiently store and release hydrogen, suggesting strong interactions and making it a viable candidate for hydrogen-based catalytic processes, particularly in the context of hydrogenation and energy storage applications.

Unprecedented Thermal Stability: A Key Advantage of Na-Doped SiBN

The performance of Na-doped SiBN went beyond just its reactivity. Compared to molecular FLPs, which are often sensitive to temperature fluctuations, the sodium-doped material displayed exceptional thermal stability. This ability to withstand extreme conditions made it particularly well-suited for heterogeneous catalysis in high-temperature industrial processes, where conventional molecular FLPs would fail due to their instability.

The combination of high thermal stability, enhanced reactivity, and the ability to reverse hydrogen adsorption/desorption makes Na-doped SiBN an ideal candidate for hydrogenation reactions, which are widely used in chemical industries for tasks such as converting unsaturated fats to saturated fats or the synthesis of pharmaceuticals.

A Game-Changer for Sustainable Catalysis

As the demand for sustainable, cost-effective industrial processes grows, researchers are turning more frequently to innovative solutions like the one developed in this study. By utilizing abundant, non-toxic materials in combination with cutting-edge polymer-derived ceramic technology, the researchers have opened up new possibilities for catalyst design that prioritize both performance and sustainability.

Professor Iwamoto and his team note that their approach could have significant implications for solid-gas phase interactions in heterogeneous catalysis, potentially providing much-needed improvements in efficiency and selectivity for a variety of industrial reactions. The groundbreaking work is not only an advancement in material science but also a significant step towards more sustainable catalysis practices in industries such as energy, chemicals, and pharmaceuticals.

Conclusion

The development of sodium-doped amorphous silicon-boron-nitride (Na-doped SiBN) as a solid-state frustrated Lewis pair (FLP) catalyst marks a significant breakthrough in catalysis research. By leveraging polymer-derived ceramics and abundant, non-toxic elements like boron and sodium, this innovative material offers exceptional thermal stability and reactivity, making it ideal for high-temperature, high-pressure industrial applications. Its ability to reversibly adsorb and desorb hydrogen, coupled with its multiple active sites, opens up new possibilities for sustainable hydrogenation reactions and other key chemical processes. This advancement paves the way for more cost-effective, eco-friendly, and efficient catalytic processes, addressing the limitations of traditional precious metal-based catalysts. As research in this area continues, Na-doped SiBN could play a crucial role in revolutionizing green chemistry and accelerating the transition to more sustainable industrial practices across various sectors.

Reference: Shotaro Tada et al, Novel Lewis Acid‐Base Interactions in Polymer‐Derived Sodium‐Doped Amorphous Si−B−N Ceramic: Towards Main‐Group‐Mediated Hydrogen Activation, Angewandte Chemie International Edition (2024). DOI: 10.1002/anie.202410961