In kitchens across the world, gallons of waste cooking oil quietly disappear down drains or gather in dusty bottles, a by-product of meals savored and discarded. For most, it is nothing more than a sticky inconvenience. But a team of scientists saw it differently. They glimpsed a hidden potential, a promise of transformation. Could something so ordinary, so overlooked, be turned into something extraordinary—a plastic that doesn’t cost the planet its future? Their curiosity led them down a path from the greasy remnants of fried food to a cutting-edge, chemically recyclable plastic.

The journey began with a simple, yet audacious idea: “Plastics are made from crude oil and petroleum by-products, so a team of scientists decided to explore if they could turn waste cooking oil into a useful plastic material, and they succeeded.” In other words, what usually ends up as environmental waste could be reborn as a high-performance material capable of rivaling the most common plastics in the world.

When Slippery Meets Sticky

Polyethylene, or PE, is the reigning champion of plastics. Its hydrocarbon backbone makes it incredibly durable, resistant to degradation, and cheap to produce. Bags, containers, and pipes all rely on its toughness. Yet the very qualities that make PE so convenient have made it a global environmental concern. It lingers in landfills, drifts in oceans, and forms part of the notorious Great Pacific Garbage Patch. The problem isn’t just quantity—it’s durability. Conventional PE refuses to break down, to return to the natural cycle.

Over the years, scientists have tried again and again to create replacements, but most alternatives stumble. A viable plastic cannot simply be sustainable; it must also be strong, versatile, and cost-effective. Enter waste cooking oil, an unassuming hero. “Each year, the world produces approximately 3.7 billion gallons of it, a largely untapped resource that could serve as a sustainable feedstock for plastic production if used appropriately.”

The researchers faced a challenge: how to take a viscous kitchen by-product and transform it into a material sturdy enough to replace PE. Their answer lay in chemistry, in the meticulous reshaping of molecules.

The Alchemy of Oil

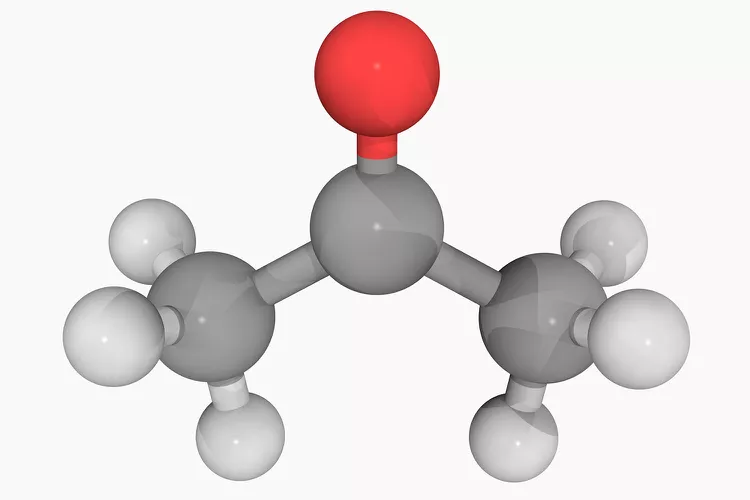

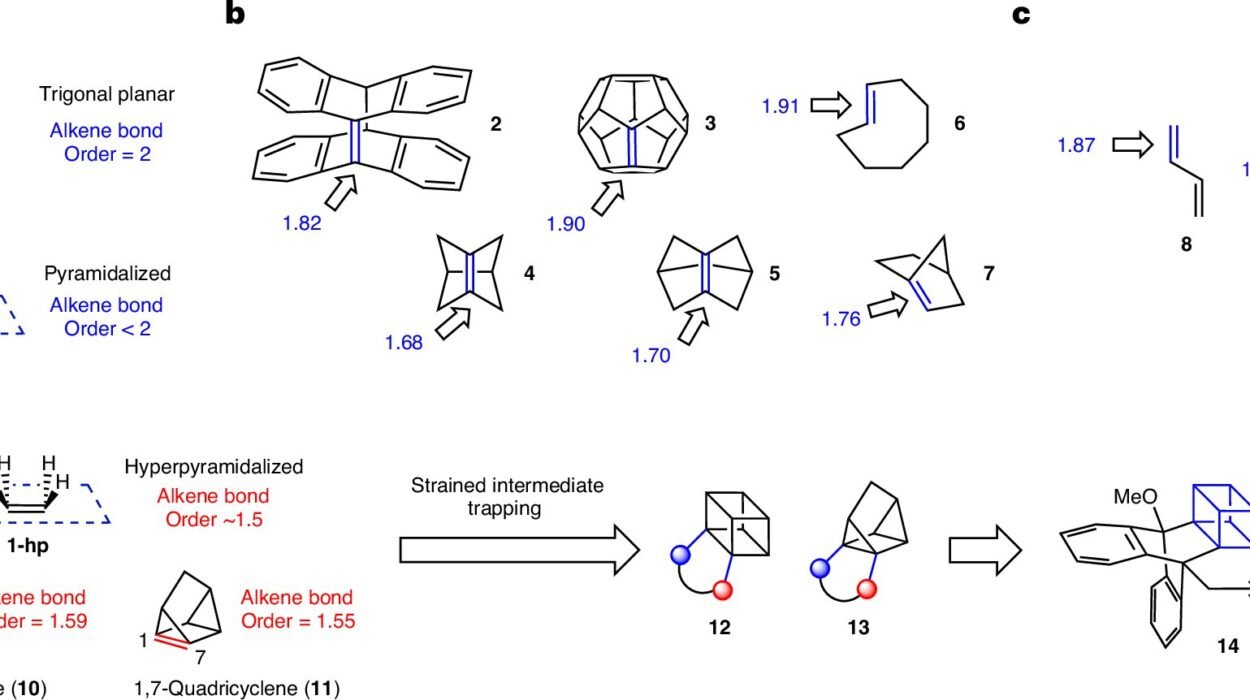

The transformation of waste cooking oil was not simple. It began with the unsaturated fatty acids in the oil, which were converted into a long-chain C19-diester using a palladium catalyst. This diester was then reduced to form a long-chain diol, the backbone that could mimic the structure of polyethylene. Glycerol, another component of cooking oil, was transformed into branched 1,3-diols.

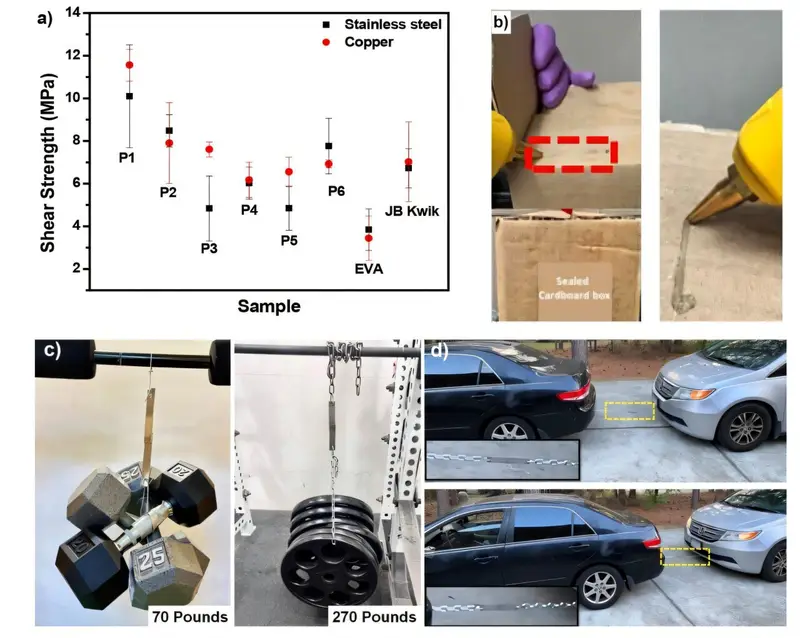

Through careful polymerization, the team combined the linear and branched molecules into a new family of polyesters, named P1 through P7. These were not just plastics in a lab—they were functional, flexible, and strong. Tests revealed that the polyesters could match, and in some cases surpass, the performance of low-density polyethylene, the workhorse plastic of modern life.

A Plastic That Comes Full Circle

The story does not end with strength alone. Unlike conventional PE, these new polyesters are chemically recyclable. They can be broken down with reagents, mixed with other plastics, and reformed under mild conditions. This characteristic is more than a technical triumph—it is a glimpse of a new paradigm, one where plastics do not become permanent pollutants but participants in a circular economy.

The adhesives created from the branched diols added another layer of surprise. Tests revealed that they could bond surfaces with astonishing strength. In a striking demonstration, the adhesive bonded stainless steel plates so firmly that it was able to pull a four-door sedan up a slight hill. These were no ordinary glues—they were materials born from what most would call waste, yet capable of feats of remarkable engineering.

Why Waste Oil Matters

The implications of this research extend far beyond laboratory experiments. By turning waste cooking oil into high-performance plastics, the team demonstrated a powerful model of sustainability. It is not simply about replacing polyethylene; it is about rethinking the way we approach materials, waste, and environmental responsibility. “These findings establish the potential of waste cooking oil as a viable feedstock for plastic production. It also demonstrates a robust waste-to-materials strategy that aligns with circular-economy principles and highlights the potential of biomass to advance sustainable plastics innovation.”

Here, in a single study, the trajectory of discarded kitchen oil is rewritten. From a slippery nuisance to a sticky marvel, it embodies the promise of science to transform problems into solutions. It shows that the future of plastics does not have to be fossil-fuel dependent, that human ingenuity can close the loop between consumption and renewal, and that even the most mundane waste can contain the seeds of innovation.

More information: Nagarjuna A. Mahadas et al, Transforming Waste Cooking Oil into Linear and Branched Polyethylene Mimics, Journal of the American Chemical Society (2025). DOI: 10.1021/jacs.5c16685