Ultrafiltration has long been one of the quiet engines of modern industry — silently purifying medicines, refining chemicals, and enabling countless everyday products. Yet despite its power, ultrafiltration has always lived with a stubborn limitation: it can only separate molecules by size. Two molecules may look identical in diameter and weight, yet behave very differently in chemistry, and current membranes simply cannot tell them apart.

But now, a breakthrough from Cornell University promises to change that story. Researchers have developed a new class of porous materials that sort molecules based on what they are, not just how big they are. This shift opens possibilities so wide that the technology could redefine how pharmaceuticals, biotech companies, and many industrial processes approach purification.

The idea is elegant, the execution intricate, and the impact potentially transformative.

The Challenge That Sparked the Innovation

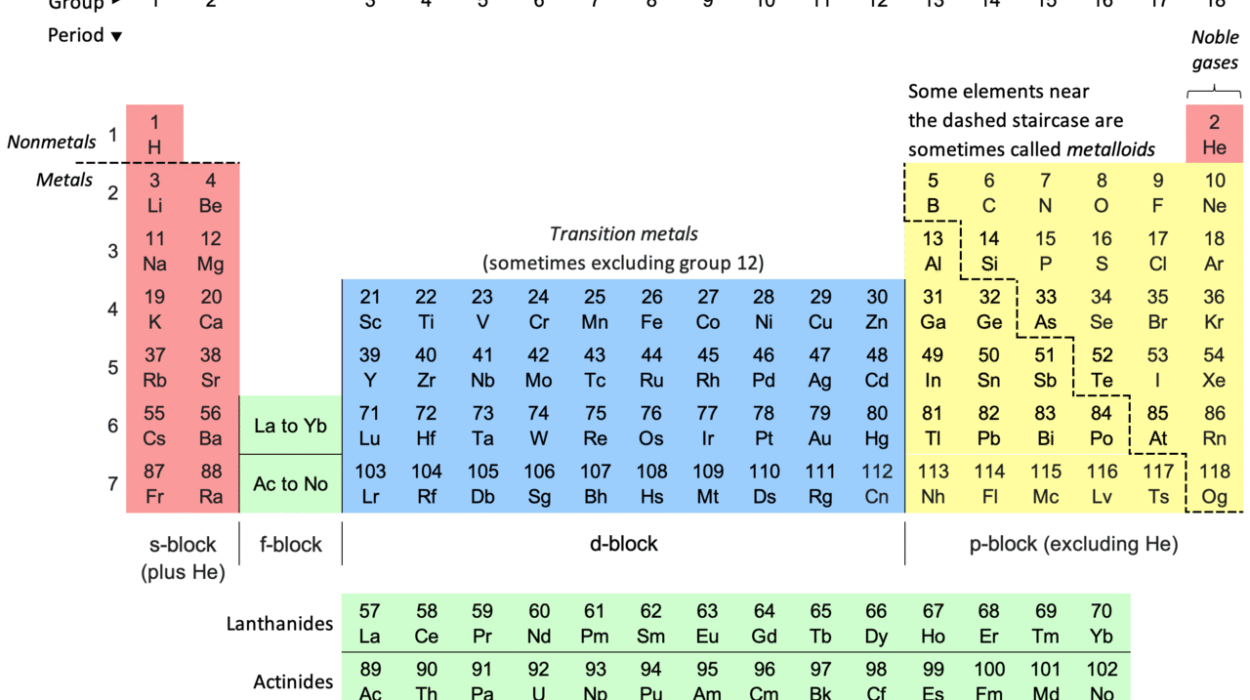

Ultrafiltration membranes work like sieves on a microscopic scale. They excel at sorting larger molecules from smaller ones, which is why they’re vital in biopharmaceutical manufacturing — especially for virus removal and protein purification.

But nature rarely makes things simple. Consider two antibodies that weigh the same and share the same shape but differ in their chemical features. To a traditional membrane, they look identical. To researchers, though, those subtle chemical differences matter enormously. They influence how effective a drug might be, how stable it remains, or how it interacts with other molecules.

Yet existing UF membranes don’t “see” chemistry — only size. Creating membranes that sense chemistry has been a dream for decades, but attempts have required complex, expensive post-processing steps that industry simply cannot adopt at scale.

This is where the Cornell team’s breakthrough begins: by blending chemistry directly into the membrane-building process itself.

How Tiny Polymer Spheres Created a Big Shift

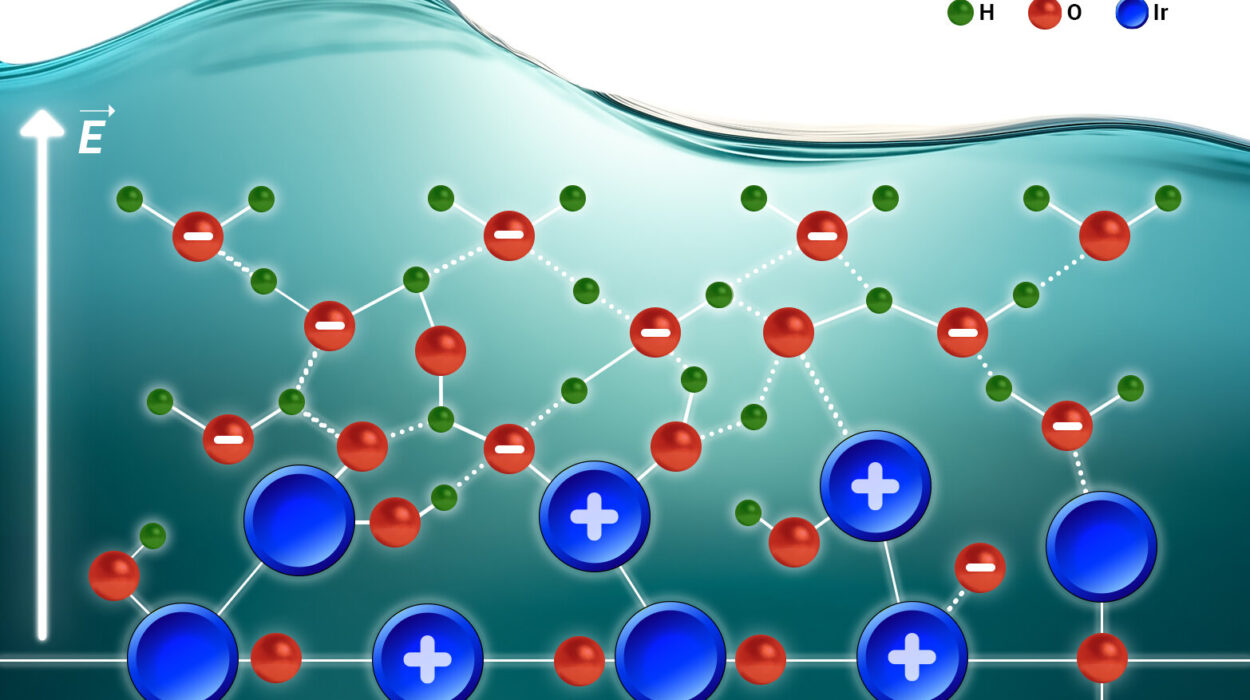

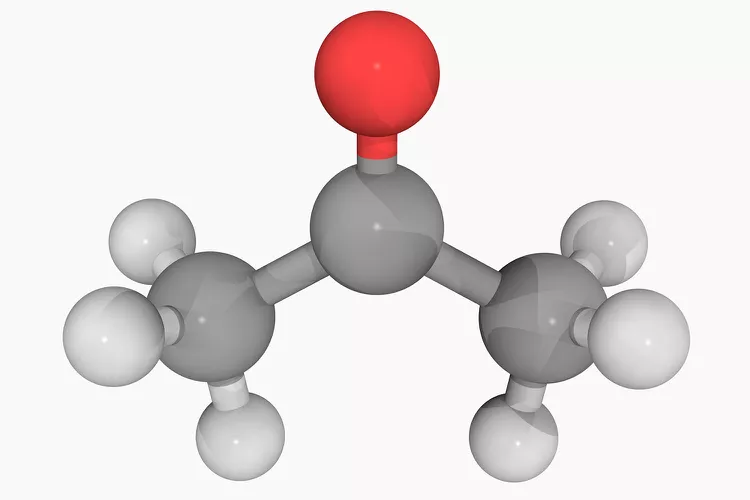

The researchers focused on block copolymer micelles — self-assembled polymer spheres only tens of nanometers wide. These micelles naturally pack together into ordered patterns, forming pores that serve as the filtration channels in a membrane.

In nature, protein channels inside cells use chemistry on their walls to distinguish between ions of nearly identical size. Inspired by this, the Cornell team wondered: what if the micelles themselves could introduce different chemistries into the pore walls? Could mixing different types of micelles create a surface with chemically diverse regions capable of selective filtration?

Lead author Lilly Tsaur set out to explore exactly this. By blending up to three different block copolymers with distinct chemical properties, she discovered that their subtle interactions — some neutral, some repulsive — determined where each type of micelle ended up during self-assembly.

The result was a membrane whose pores were not uniform but carried different chemical personalities, enabling them to attract or repel specific molecules.

This means membranes no longer have to judge molecules solely by size. They can now distinguish based on affinity, a leap that fundamentally changes what ultrafiltration can achieve.

The Difficult Journey to Visualizing the Invisible

While the concept was simple in theory, the real-world experimentation was anything but.

To understand how the micelles arranged themselves, Tsaur used scanning electron microscopy to examine hundreds of samples. While the images revealed pore structures in stunning detail, they did not reveal chemistry. Two different micelles might produce pores that look similar, yet behave differently.

To overcome this obstacle, Tsaur turned to machine learning. By training models to detect extremely subtle pattern differences — ones invisible to the human eye — she was able to map out where each micelle type resided in the membrane.

Meanwhile, on the theoretical front, chemical engineering professor Fernando Escobedo used molecular simulations to understand why the micelles arranged themselves the way they did. But simulating massive numbers of interacting micelles is notoriously challenging. The systems are too complex, and the assemblies too dynamic.

Escobedo and his colleague Luis Nieves-Rosado built highly coarse-grained computational models, calibrating them repeatedly to capture the right scales and interactions. Their simulations revealed the rules governing how micelles negotiate space with one another — a key step in understanding how to control pore chemistry during fabrication.

Together, the experimental imaging and simulations formed a complete picture of how chemically diverse pores can be created reliably and at scale.

A Breakthrough Rooted in Practicality

What makes this discovery so powerful is not just the science, but its compatibility with existing industrial processes.

The Wiesner group’s earlier advances in block copolymer self-assembly already led to Terapore Technologies, a company that uses their method to produce affordable, high-performance ultrafiltration membranes for virus filtration in biopharmaceuticals.

Now, companies using this established manufacturing framework could introduce chemical selectivity simply by changing the recipe — the “magic dust,” as Wiesner calls it. No extra steps, no expensive processing, no major infrastructure changes.

Just a smarter way of building the membrane from the beginning.

This is the kind of innovation industry embraces: simple to adopt, dramatic in effect.

What Chemically Tuned Membranes Make Possible

If ultrafiltration membranes can sort molecules by chemical affinity, an enormous new set of applications becomes possible.

In pharmaceuticals, separating similar antibodies or protein variants becomes far more refined. Drug purity improves. Production steps become more efficient. New therapeutic avenues open.

In biotechnology, selecting specific molecular species could streamline the creation of complex biological products.

Beyond filtration, these membranes could inspire materials with built-in responsiveness — smart coatings that change behavior when exposed to pollutants, or biosensors designed to detect particular molecules with high sensitivity.

And because this technology is grounded in self-assembly — a technique nature itself uses — it could evolve into areas we cannot yet predict.

More information: Lieihn Tsaur et al, Film surface assemblies from chemically distinct block copolymer micelles, Nature Communications (2025). DOI: 10.1038/s41467-025-65278-x