For decades, scientists have admired plexiglass—formally known as polymer glass—for its transparency, versatility, and resilience. From eyeglasses and aquarium walls to museum enclosures, this lightweight substitute for glass has shaped our world in ways we often take for granted. Yet despite its strengths, plexiglass has always lived with a hidden weakness: the struggle to be both strong and tough at the same time.

Strength and toughness may sound like synonyms, but in the language of materials science, they are very different. Strength is the ability to withstand stress without deforming, while toughness is the ability to absorb energy without shattering. A strong material can hold out under pressure but may snap suddenly, like brittle glass. A tough material can bend and yield, redistributing stress and resisting cracks, but it may sacrifice some rigidity. Combining both properties has been the holy grail for polymer glasses, yet researchers repeatedly ran into a wall known as the strength–toughness trade-off.

Now, a team of scientists in China has discovered a way around this age-old dilemma. Their breakthrough, published in Physical Review Letters, suggests that plexiglass can be made stronger, tougher, and easier to process by blending in a surprising new ingredient: single-chain nanoparticles.

Rethinking the Recipe

To understand why this discovery is such a leap forward, imagine plexiglass as a giant bowl of tangled spaghetti. The strands—long chains of polymer molecules—intertwine and hold together, creating the solid material we know. The challenge is that when stress is applied, those strands don’t always share the load evenly. Weak spots appear, cracks form, and the material can fail.

For years, scientists tried to solve this by tossing in rigid nanocrystals, like adding tiny reinforcing rods to the spaghetti. The strategy worked in part: the material grew stronger and tougher. But there was a catch. The rigid particles clogged up the mixture, making the material thick and sticky, much harder to process into useful forms. What looked like progress only created a new trilemma: strength, toughness, and processability could not be optimized all at once.

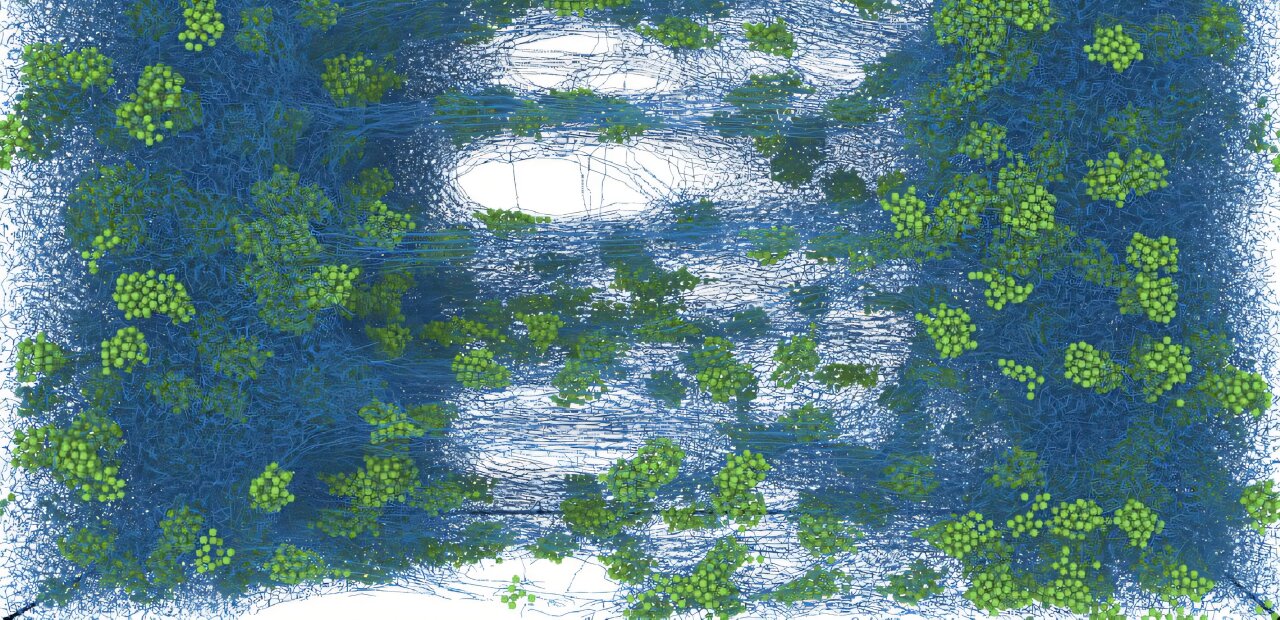

That is where single-chain nanoparticles—or SCNPs—change the game. Unlike rigid particles, SCNPs are made from the same polymer strands as the matrix, only folded into compact, ball-like structures. Imagine rolling up a spaghetti strand into a neat, springy ball and tossing it back into the pot. These balled-up chains integrate seamlessly with the surrounding polymers, but they bring special properties that ordinary strands lack.

How SCNPs Reinforce Plexiglass

The Chinese researchers explored two approaches: blending SCNPs directly into the polymer glass or chemically cross-linking them with the surrounding material. In both cases, they tested the results with mechanical experiments, electron microscopy, and computer simulations.

What they found was remarkable. Under stress, the SCNPs didn’t just sit passively inside the plexiglass—they moved. Like agile knots within the matrix, they shifted around, forming stabilizing ties between microscopic fibrils, the tiny thread-like structures that stretch and strain under force. This movement delayed the formation of cracks and crazes, the small fracture-like patterns that usually spell doom for plexiglass. In essence, the SCNPs acted like internal shock absorbers, distributing stress across the material and keeping it intact.

But the benefits did not stop there. Because SCNPs have soft, deformable surfaces, polymer chains from the surrounding matrix could slide across them. This sliding action worked like a lubricant at the molecular scale, reducing the material’s viscosity when melted. Lower viscosity means easier processing—plexiglass that can be molded, shaped, and manufactured without the sticky complications caused by rigid nanocrystals.

In a single stroke, the SCNPs broke the trade-off. They created a material that was not only stronger and tougher but also easier to work with, a feat long considered impossible.

Why Strength and Toughness Together Matter

To appreciate the significance, think about everyday uses of plexiglass. A pair of eyeglasses must resist scratching and shattering; a museum case must remain sturdy yet light; an aquarium wall must hold tons of water pressure without cracking. Each of these applications demands both strength and toughness. One without the other is simply not enough.

When materials fail to balance these properties, the consequences can range from the annoying—a scratched lens—to the catastrophic—a shattered enclosure. By overcoming the trade-off, SCNP-reinforced plexiglass could lead to safer products, more reliable designs, and entirely new applications in industries where durability and safety are paramount.

From the Lab to the World

The researchers’ work is not just a clever tweak of materials—it represents a new philosophy in polymer science. Instead of adding rigid reinforcements from the outside, they used the material’s own molecular language, folding single chains into nanoparticles that integrate naturally. This biomimetic elegance—letting the polymer strengthen itself through internal architecture—could inspire new approaches far beyond plexiglass.

The use of advanced techniques such as molecular dynamics simulations further highlights the depth of this research. By visualizing how SCNPs interact with the polymer matrix at the atomic level, the scientists could see exactly how stress is absorbed and redistributed. This merging of experiment and computation provides confidence that the breakthrough is not a laboratory curiosity but a pathway to practical materials.

The Future of Polymer Glass

What lies ahead for SCNP-enhanced plexiglass? The possibilities are wide open. Stronger and tougher plexiglass could revolutionize safety equipment, from protective face shields to bullet-resistant barriers. Lighter, more durable enclosures could benefit aerospace, automotive, and architectural applications. Even consumer goods like smartphones and wearables could gain from a material that resists both impact and fracture while remaining easy to mold into sleek designs.

The discovery also suggests that the long-standing trade-offs in materials science may not be as rigid as once thought. With the right nanoscale design, properties that once seemed mutually exclusive can be harmonized. This principle could apply to countless polymers, potentially leading to better plastics, composites, and coatings.

A Glimpse Into Tomorrow’s Materials

At its core, this breakthrough is about more than plexiglass. It represents a growing trend in science: using the smallest building blocks of matter to reshape the world we live in. Nanotechnology, once the stuff of speculation, is now guiding how we design everything from medicines to solar panels. In this case, tiny folded chains have unlocked a solution to a problem that resisted decades of effort.

There is something profoundly human about this achievement. For centuries, we have shaped matter with hammers, furnaces, and presses, imposing our will on the physical world through brute force. But now, by understanding molecules and their interactions, we are beginning to work with nature rather than against it. Instead of bending materials until they break, we are teaching them how to bend without breaking.

The story of single-chain nanoparticles in plexiglass is a glimpse into this future—a future where the age-old conflicts in materials science are resolved not by compromise but by creativity. Stronger, tougher, more versatile polymer glasses may soon surround us, quietly protecting and beautifying our world, thanks to the power of innovation at the nanoscale.

More information: Lei Zhang et al, Single-Chain Nanoparticles Break the Strength-Toughness-Processability Trilemma in Polymer Glasses, Physical Review Letters (2025). DOI: 10.1103/nm5z-2hxm