Robots have long been associated with rigid metal arms, powerful motors, and heavy industrial machinery. These designs excel at repetitive, forceful tasks—welding steel, assembling cars—but they falter when asked to perform delicate movements or navigate cramped, twisting spaces.

Now, researchers at POSTECH (Pohang University of Science and Technology) have created something that defies the traditional image of a robot: a paper-thin, flexible actuator that moves with the agility of living muscle. This breakthrough, published in Nature Communications, could reshape how robots operate in both surgical theaters and industrial plants.

The innovation bridges a gap that has frustrated engineers for years—the challenge of combining strength and flexibility in a single robotic system. Until now, machines were often forced to choose one or the other.

Inspired by the Human Body’s Own Machinery

The research team, including Dr. Hyung Gon Shin from Samsung Electronics’ Future Robotics Division (formerly a Ph.D. researcher at POSTECH), and Professors Keehoon Kim and Wan Kyun Chung from POSTECH’s Department of Mechanical Engineering, turned to biology for answers.

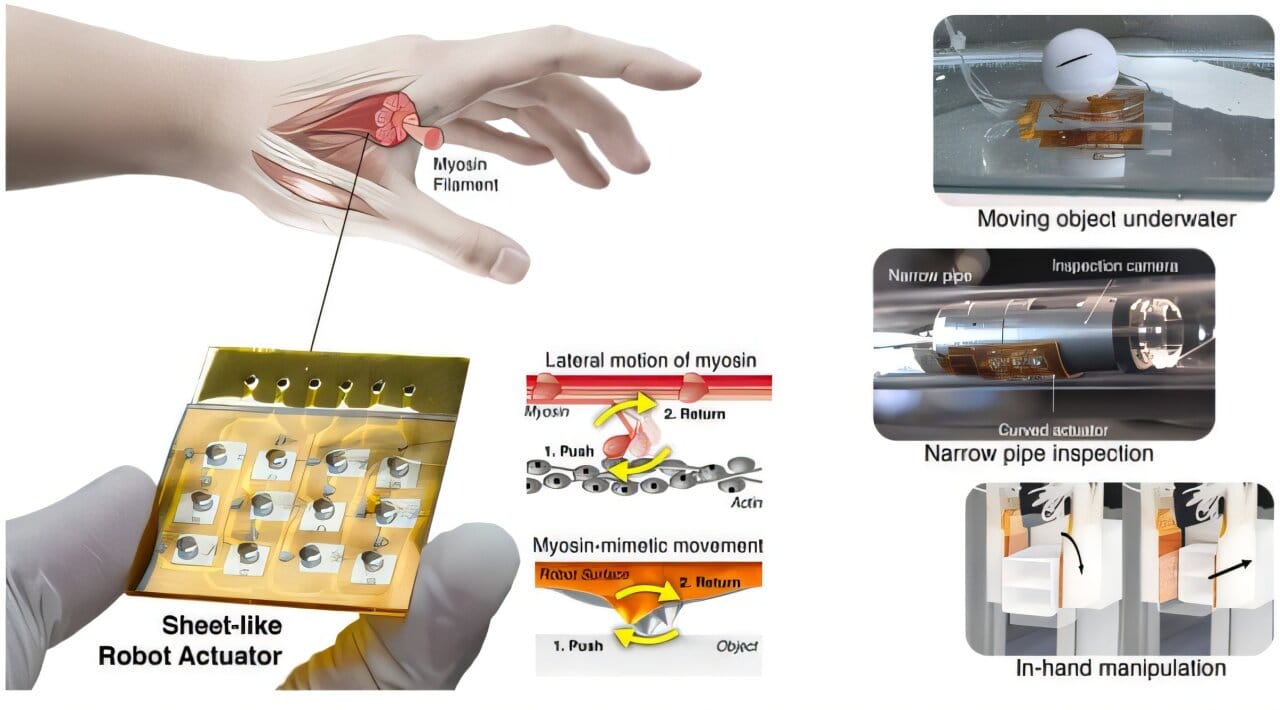

Their inspiration came from myosin, a protein inside human muscles. Myosin works through a series of tiny contractions, generating large, coordinated movements. In our bodies, these micro-motions accumulate to create everything from a runner’s stride to the precise flick of a pianist’s finger.

The team replicated this principle in a pneumatic actuator—a soft, air-powered device—crafted as a thin, sheet-like structure. At first glance, it could be mistaken for a piece of high-tech wrapping paper. But hidden within its layers is an intricate network of air chambers and channels, carefully designed to produce movement when pressurized.

How It Works: Small Motions, Big Impact

Inside the actuator, dozens of tiny air chambers expand and contract as air is pumped in sequence. These micro-movements build upon one another, producing significant overall motion. The surface can bend, twist, or extend—moving in six different directions: up, down, left, right, rotation, and tilt.

This multidirectional capability allows the robot to crawl like a caterpillar even when bent, using its surface protrusions as tiny feet. By precisely controlling the timing and pressure of the air flow, the team can adjust both the speed and distance of each movement.

In laboratory tests, the actuator demonstrated remarkable versatility. It delicately grasped and manipulated objects with the precision of human fingers, successfully performed tasks underwater, and navigated narrow spaces where conventional robots simply could not go.

From Operating Rooms to Factory Floors

The potential applications are vast. In medicine, this technology could enable minimally invasive surgical robots that travel through small incisions or natural openings in the body, performing procedures with both gentleness and strength.

In industry, flexible robots like this could inspect and maintain complex machinery, clean pipelines, or handle fragile products on assembly lines. The ability to work in tight, intricate environments could save companies both time and money while reducing the need for disassembly of large equipment.

Even home robots could benefit. Imagine a cleaning device that slithers into every corner of your kitchen or a caregiving assistant that can interact with people safely and responsively.

A Step Toward the Future of Soft Robotics

A key part of the research was the development of a mathematical model to predict the actuator’s movements. This model allows engineers to design new shapes and configurations for different tasks, making the technology adaptable to a wide range of real-world challenges.

Professor Keehoon Kim described the achievement as “successfully integrating a complex three-dimensional pneumatic network within a thin and flexible structure, enabling multi-directional movements through a bio-inspired approach.”

He added, “We hope this technology will be applied in various fields, including surgical robots, collaborative robots in industrial settings, and exploration environments.”

Beyond Machines: A More Human Touch

What makes this breakthrough so exciting is not just the mechanics, but the philosophy behind it. Rather than forcing machines to mimic the brute strength of industrial tools, this approach embraces the subtlety of biology. By looking to the human body for inspiration, the researchers have created a robot that moves less like a machine and more like a living organism.

In doing so, they’ve brought us closer to a future where robots aren’t just tools—they’re partners, capable of working alongside humans in ways that are safe, adaptive, and incredibly precise.

From the depths of the human body to the innermost parts of industrial machinery, this paper-thin robot may soon slip into places no machine has gone before, quietly reshaping both technology and the world it serves.

More information: Hyung Gon Shin et al, Soft and flexible robot skin actuator using multilayer 3D pneumatic network, Nature Communications (2025). DOI: 10.1038/s41467-025-60496-9