In a split second, your fingers graze the searing metal of a stovetop. Before your brain even registers the heat or forms the thought of danger, your arm has already recoiled in a blur of motion. This is the withdrawal reflex, a biological masterpiece where sensory nerves in the skin bypass the brain entirely, sending a lightning-fast signal to the spinal cord to activate the muscles. Only after the movement has started does the brain receive the memo that something went wrong. For humans, this delay-free reaction is the difference between a minor sting and a life-altering burn.

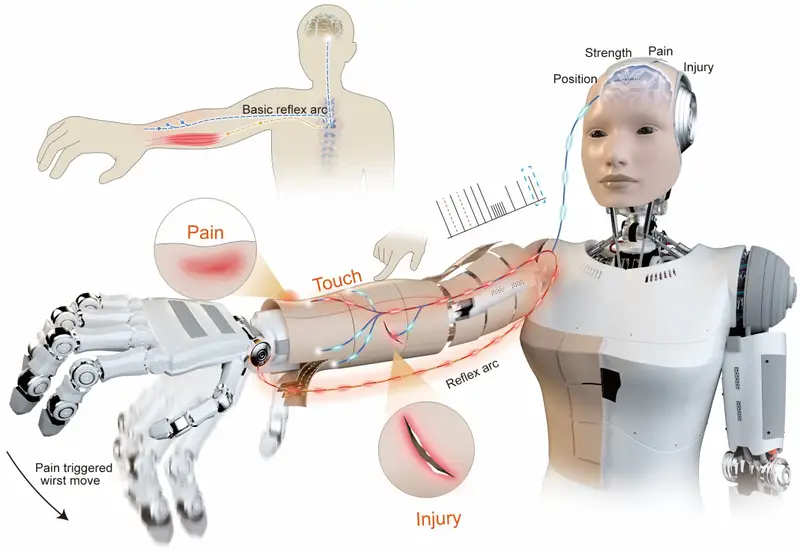

For the humanoid robots currently being developed to work alongside us, this split-second grace period hasn’t existed. Traditionally, if a robot encounters a hazard, its sensors must send raw data to a central processing unit (CPU), wait for the system to crunch the numbers, and then dispatch a command to the arm’s actuators. In the high-stakes world of mechanical hardware, even a micro-delay can lead to catastrophic damage. However, a team of scientists in China has now bridged this gap between biology and machinery, creating a neuromorphic robotic e-skin (NRE-skin) that allows machines to not only touch the world but to “feel” pain and react with the same instinctive urgency as a human being.

The Ghost in the Machine

Most modern robotic skins are little more than sophisticated pressure pads. They can detect that they are being touched, but they lack the “intelligence” to interpret the meaning behind that contact. They cannot distinguish between a friendly pat and a damaging blow without a heavy lift from the central computer. The NRE-skin changes this dynamic by mimicking the hierarchical architecture of the human nervous system.

This new electronic skin is composed of four distinct layers. The outermost layer serves as a protective epidermis, shielding the internal components from the environment. Beneath this surface lies a complex web of sensors and circuits designed to behave like biological nerves. This system doesn’t just wait for something to happen; it maintains a constant “heartbeat.” Every 75 to 150 seconds, the skin sends a small electrical pulse to the robot’s CPU, even when nothing is touching it. This serves as a continuous status report—a way for the skin to whisper, “Everything is fine.”

If the skin is ever cut or significantly damaged, this steady pulse stops immediately. This silence acts as an alarm, informing the robot exactly where the injury has occurred so it can alert its owner. This internal monitoring system ensures that a robot isn’t walking around with a “numb” or broken limb without the system realizing it.

When Touch Becomes a Warning

The true breakthrough of the NRE-skin lies in how it categorizes physical interaction. When the skin is touched normally, it generates a signal known as a spike. These spikes carry precise data about the amount of pressure being applied, which is then sent to the CPU for standard processing. This allows the robot to understand the nuance of a gentle grip or a steady hand.

However, the system is programmed with a preset threshold for force. When a touch crosses the line from “pressure” to “extreme,” the skin recognizes it as pain. At this critical moment, the architecture shifts. Instead of waiting for the CPU to decide what to do, the skin sends a high-voltage spike directly to the motors.

By bypassing the central processor, the robot executes a local reflex. The arm pulls away instantly, mimicking the human withdrawal reflex. This decentralized approach ensures that the robot protects itself from harm at the speed of electricity, rather than the slower speed of computer logic. This neural-inspired architecture ensures that the machine’s primary directive—self-preservation—is handled at the source of the sensation.

A Modular Solution for a Fragile World

Even with lightning-fast reflexes, accidents are inevitable in the unpredictable environments of homes and hospitals. Recognizing that robots will eventually need “surgery,” the researchers designed the NRE-skin with a clever, Lego-like modularity. The skin is not one continuous, irreplaceable sheet; instead, it is made of magnetic patches.

If a section of the skin is compromised, there is no need for a complex, hours-long repair process. Because of the magnetic design, an owner can simply snap off the damaged section and click a new, functional patch into place in a matter of seconds. This quick-release repair system ensures that maintenance is as intuitive as the skin’s reflexes, allowing the robot to return to its duties with minimal downtime.

Why Feeling Pain Makes Robots Safer

As these machines move out of the controlled environments of factories and into our daily lives as empathetic service robots, the ability to feel becomes a safety requirement rather than a luxury. The development of the NRE-skin represents a shift toward more intuitive human-robot interaction.

This research matters because it changes the fundamental relationship between a machine and its surroundings. By giving a robot the ability to detect active pain and injury, we are creating machines that are more aware of their own physical limits. A robot that can “feel” is a robot that can avoid breaking itself—and more importantly, avoid causing accidents in a crowded home or a busy hospital ward.

The team is already looking toward the future, working to refine the skin’s sensitivity. The next goal is to ensure the system can process multiple touches simultaneously without becoming confused, further closing the gap between the mechanical and the biological. By teaching robots to feel the sting of the world, we are ironically making them much more capable of navigating it safely.

Study Details

Yuyu Gao et al, A neuromorphic robotic electronic skin with active pain and injury perception, Proceedings of the National Academy of Sciences (2025). DOI: 10.1073/pnas.2520922122