Across the wide, open fields of modern agriculture, machines hum tirelessly. They dig, plant, and sow with precision, feeding billions of people around the world. But beneath this harmony of technology and nature lies a quieter problem—one that farmers, engineers, and environmentalists have been struggling with for years.

To make planting more efficient, farmers rely on solid lubricants — powders that coat seeds to keep them flowing smoothly through complex machinery. Without these lubricants, seeds can jam or clump together, halting the planting process and wasting precious time during the short window of a growing season.

For decades, the most common lubricants have been talc and microplastic-based powders. They work, but at a cost. These materials can harm both people and the planet. When inhaled, talc dust can pose respiratory risks to farmers. Microplastics, meanwhile, don’t degrade — they linger in the soil, polluting farmland, seeping into waterways, and threatening pollinators and wildlife.

But now, a team of researchers has developed something extraordinary — a sustainable, biodegradable alternative that promises to change the way farming interacts with the environment. Their creation is not only safer but also more efficient, more affordable, and inspired by nature itself.

A New Kind of Lubricant, Born from Plants

The groundbreaking work, published in the journal Matter under the title “Graph Theory Based Bioderived Solid Lubricant,” comes from scientists led by Dhanush Udayashankara Jamadgni and Professor Martin Thuo at North Carolina State University (NC State).

Their invention is a new class of non-toxic, biodegradable lubricants made from cellulose — the same natural material that makes up the cell walls of plants. Cellulose is abundant, renewable, and safe. By transforming it into a fine powder, the researchers created a lubricant that not only performs better than conventional options but also leaves no harmful trace in the soil or air.

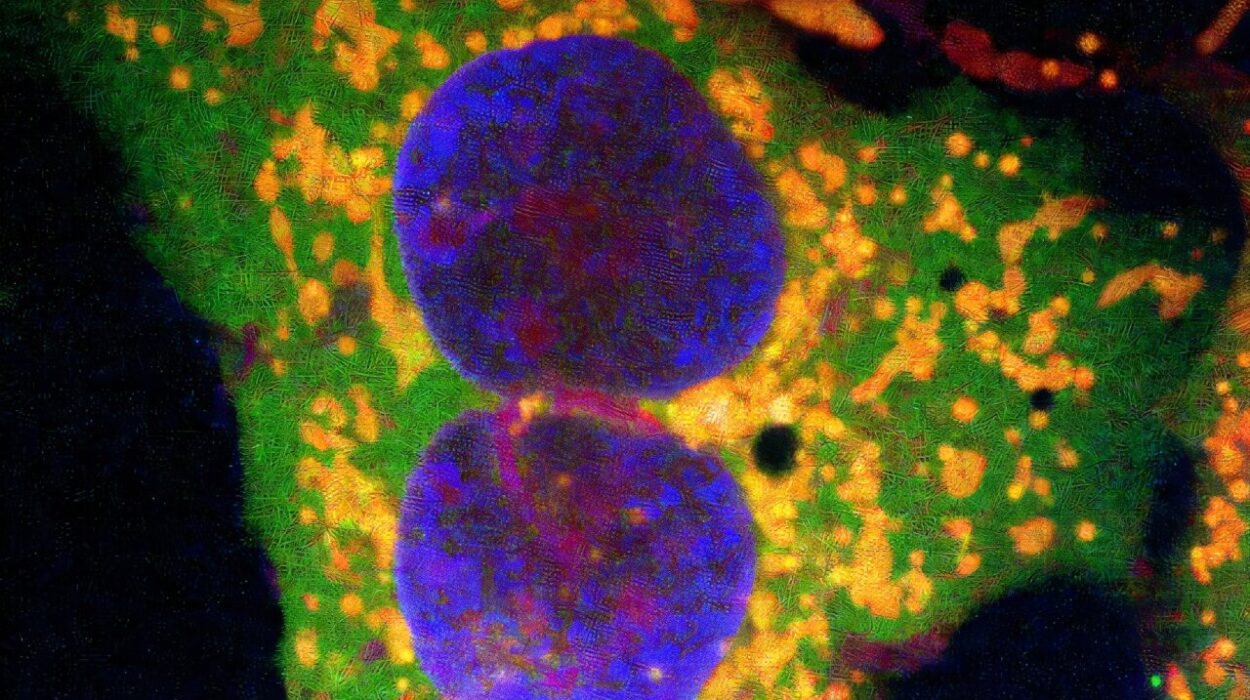

When you look at it, the cellulose lubricant appears as a soft, white powder. But under a microscope, it reveals a fascinating structure — millions of tiny fibers, each between 0.2 to 2 millimeters long and 10 to 40 microns wide. The surface of these fibers is coated with hydrophobic (water-repelling) particles, which help them stay dry and slick.

Together, these features make the new lubricant a quiet marvel of sustainable engineering.

The Science of Smooth

To understand how this new lubricant works, imagine a handful of seeds moving through a planting machine. Without lubrication, they rub against each other, generating friction that causes jams and clumps. The cellulose lubricant prevents this in two ingenious ways.

First, the fibers themselves are smoother than the seed surface. When mixed with seeds, they act like countless tiny cushions, slipping between the seeds and reducing the mechanical friction that causes clogging.

Second, the hydrophobic coating on each fiber repels water — even in humid conditions. Moisture is the enemy of seed flow, causing them to stick together like damp sand. The new lubricant solves this problem by keeping both the seeds and the lubricant itself dry and slippery.

The result? Seeds move freely, even in the kind of damp, unpredictable weather that would otherwise make planting nearly impossible.

Outperforming the Old Guard

When the team tested their new cellulose-derived lubricant in the field, the results were nothing short of remarkable.

In proof-of-concept trials with corn and soybean seeds, the plant-based lubricant performed five times better than the best commercial talc lubricants and twenty-five times better than microplastic lubricants. Even more impressive, when tested with smaller seeds — like mustard or canola — and in conditions of high humidity, the performance gap widened dramatically.

“Right now, it is difficult for farmers to sow their fields when there is high humidity or wet weather because moisture causes the seeds to stick together and clog the machinery,” explains Professor Thuo. “Our lubricant handles wet conditions beautifully — even up to 80% humidity — because of how it interacts with water.”

Here’s the secret: the cellulose fibers don’t simply repel moisture; they manage it intelligently. When water vapor seeps between the hydrophobic particles coating the fibers, it’s absorbed by the cellulose core. This does two things — it reduces the moisture available to make the seeds sticky and slightly softens the fibers. Then, as the seeds move through the machinery, the water is gently squeezed out again, making the lubricant even slicker.

It’s an elegant cycle — absorb, adapt, release — mirroring the way natural systems regulate themselves.

A Hidden Benefit: Protecting Pollinators and Farmers

As the team continued testing, they discovered something they hadn’t anticipated — an environmental bonus that could have wide-reaching implications.

Most agricultural seeds today are coated with a thin layer of nutrients and pesticides designed to protect and nourish the young plant. However, when using traditional lubricants like talc, this coating often gets scraped off during planting. The tiny particles are then released through the machine’s exhaust system, forming a toxic cloud that drifts into the air.

This invisible pollution poses real dangers — not just to farmers, who breathe it in, but also to pollinators like bees, whose health is already under severe threat from pesticide exposure.

The new cellulose-based lubricant drastically reduces this problem. Because its fibers are softer and more flexible, they minimize abrasion on the seed surface. Far less of the seed coating is lost during planting, meaning less pesticide dust escapes into the environment.

“It was an unexpected but beautiful result,” says Jamadgni. “We were trying to solve a mechanical problem and ended up also helping reduce toxicity in the air and soil.”

Designed for Sustainability and Reuse

The environmental thoughtfulness doesn’t stop there. The researchers designed their cellulose lubricant to be both biodegradable and recoverable.

In modern seed-planting systems, a vacuum mechanism is often used to draw seeds into place before they are released into the soil. The team found that their cellulose fibers could be easily filtered out of this vacuum system — meaning very little of the lubricant escapes into the environment.

That opens the door to reuse or proper disposal — a simple but powerful step toward reducing agricultural waste.

The Power of Collaboration and Graph Theory

In parallel with developing the lubricant itself, the team also created an analytical model — a mathematical tool that could revolutionize how scientists design future lubricants.

Working with graph theory experts from the University of Michigan and the University of Southern California, they built a model that represents the interactions between different materials as a network of nodes and connections. By analyzing these relationships, researchers can predict how potential materials will behave as lubricants — without having to test every possibility in the lab.

“Essentially, we’ve defined a parameter space using graph-based techniques that simplifies what is an incredibly complex system,” explains Thuo. “It helps us quickly identify promising candidates for solid lubricant applications.”

This approach doesn’t just make the research more efficient — it accelerates innovation. With it, scientists can explore a vast range of natural and synthetic materials to find greener, safer alternatives for industries beyond agriculture.

Beyond the Field: A Model for Sustainable Innovation

The implications of this discovery reach far beyond farming. Solid lubricants are used in countless industries — from manufacturing to medicine, aerospace to robotics. Replacing toxic or non-biodegradable lubricants with safer, plant-derived options could reduce environmental pollution on a massive scale.

But perhaps the most inspiring part of this story is not the chemistry — it’s the philosophy behind it. The cellulose lubricant is a testament to what can happen when science listens to nature. Instead of trying to overpower or outsmart the environment, the researchers worked with it, drawing from the natural properties of cellulose to solve a human-made problem.

It’s a reminder that sustainability isn’t just about finding alternatives; it’s about rethinking the way we design and interact with materials.

Farmers, Science, and the Future of the Earth

When the new lubricant was tested in blind field trials, farmers noticed the difference immediately. The seeds flowed smoothly, even in wet conditions, and the machines ran cleaner. There was less dust, less waste, and more confidence in getting the job done, regardless of the weather.

For the farmers who tested it, this innovation wasn’t just about convenience — it was about hope. Hope that agriculture, the foundation of human civilization, can evolve into something more harmonious with the living world it depends on.

“We’ve developed a new class of safe solid lubricants that are effective and nontoxic,” says Jamadgni. “It’s a small step, but one that could have a big impact.”

A Greener Future, One Seed at a Time

Every great change begins with something small — a spark of curiosity, a handful of powder, a single seed. In this case, that small thing could transform one of the world’s most essential industries.

By replacing toxic lubricants with biodegradable, plant-based ones, scientists are helping farmers protect their health, preserve pollinators, and restore soil ecosystems — all while improving efficiency. It’s a triumph of imagination and empathy as much as science.

In the gentle glide of a seed through a planting machine, there is a story of renewal — of how human ingenuity can heal what it once harmed. This new cellulose lubricant is more than a technical innovation. It’s a symbol of what the future of agriculture could be: clean, sustainable, and deeply connected to the rhythms of the Earth itself.

And as those seeds settle into the soil, nurtured by science and guided by care, they carry with them the promise of a greener tomorrow.

More information: Graph Theory Based Bioderived Solid Lubricant, Matter (2025). DOI: 10.1016/j.matt.2025.102474. www.cell.com/matter/fulltext/S2590-2385(25)00517-X