It’s not often that an insect’s feeding tube becomes the key to a major technological breakthrough. Yet in a quiet lab at McGill University in Canada, researchers have found exactly that: the proboscis of a mosquito. In a fascinating twist, these scientists turned nature’s tiny feeding appendage into a precision tool for 3D printing—one that is not only highly efficient but also sustainable.

This innovative idea stemmed from a common engineering challenge: how do you create ultra-fine, low-cost nozzles for high-resolution 3D printing? The answer wasn’t to invent something entirely new. Instead, it was to look closely at something old, something natural, and use it as inspiration for modern design.

A Quest for Precision and Sustainability

For years, 3D printing has been used to create incredibly detailed objects, from dental implants to aerospace components. The technology involves building up layers of material to form solid shapes with intricate designs. But here’s the catch: the more precise the print, the more expensive the tools required.

Traditional 3D printing nozzles, which are responsible for depositing material in tiny, controlled amounts, can cost upwards of $80 apiece. They are often made of metal or plastic, which are durable but also nonbiodegradable. Given the growing need for sustainable alternatives in technology, McGill’s researchers realized they needed to think outside the box—perhaps even outside the laboratory.

So, they asked themselves: could nature provide a solution?

Nature’s Blueprints for Innovation

The McGill team had already explored a variety of potential solutions, all grounded in traditional engineering approaches. Yet none seemed to fit the bill. They needed a nozzle that was precise, affordable, and biodegradable. That’s when they decided to look to nature for inspiration, choosing the proboscis of a mosquito for its unique properties.

Why a mosquito? The choice might seem unusual, but the proboscis—a specialized feeding tube used by female mosquitoes—was a perfect fit. The mosquito’s proboscis is not just any ordinary tube. It is remarkably fine, with an inner diameter of just 20 micrometers, which is about half the width of a human hair. This is an incredible degree of precision, far finer than the best commercially available printing nozzles.

The mosquito proboscis also has other qualities that make it a perfect candidate for a 3D printing nozzle. It is stiff and nearly straight, providing stability during the printing process. It can withstand the pressure of about 60 kilopascals—the equivalent of what is needed to inject thick bio-inks without bursting. And perhaps most importantly, it is biodegradable, making it an environmentally friendly alternative to conventional materials.

Testing the Bio-Nozzle

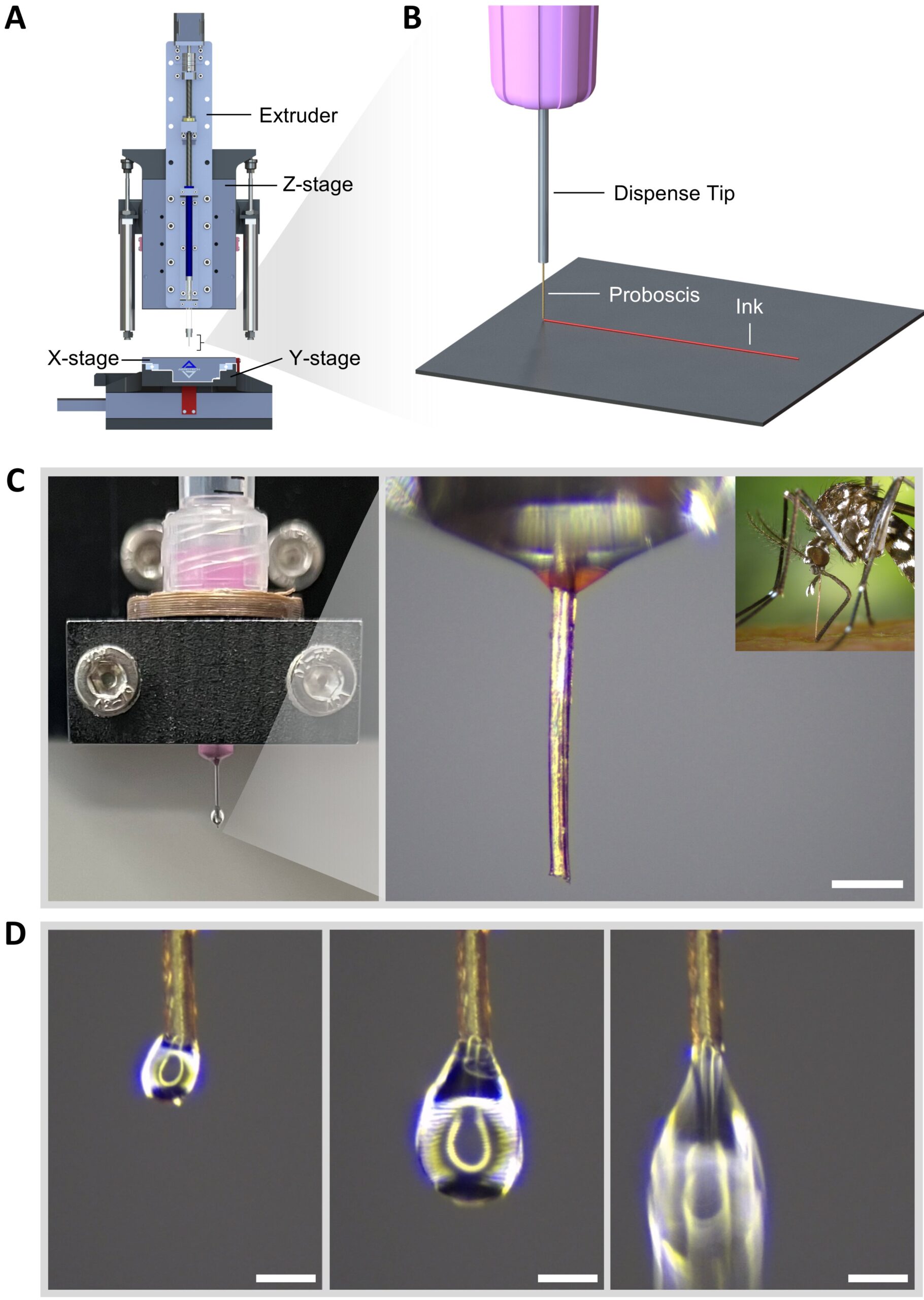

Once they had their natural “bio-nozzle,” the researchers moved on to the next challenge: testing it in a real-world application. They built a custom 3D printer, which they aptly named a 3D necroprinter, and mounted the mosquito proboscis onto a standard dispensing tip. The goal was to use it to print bioinks for creating specialized bioscaffolds—tiny structures used in biomedical research to support cell growth—and intricate microstructures with fine details.

There was one major hurdle left to overcome: the proboscis’s inherent fragility. While it was strong enough to handle pressure for printing, it was also delicate enough to break under too much force. So, the team ran a series of tests to determine the maximum pressure the proboscis could tolerate before it burst. Once they found the “burst threshold,” they established a safe operational guideline and began printing.

The results were impressive. The bio-nozzle allowed the team to print bioscaffolds with the necessary precision and fine detail. Some of the printed lines were as narrow as 20 micrometers, making them not only functional but also highly accurate. The experiments proved that this natural material could be used effectively in high-precision 3D printing, creating complex, fine microstructures with ease.

Beyond the Lab: Toward Real-World Applications

The success of this project isn’t just about the cool factor of using a mosquito’s proboscis as a 3D printing tool. It opens up a new realm of possibilities for sustainable manufacturing and medical research. As the team notes, “By introducing biotic materials as viable substitutes to complex engineered components, this work paves the way for sustainable and innovative solutions in advanced manufacturing and microengineering.”

This breakthrough isn’t just an academic exercise—it has the potential to change the way we think about manufacturing and biomedical applications. By moving beyond plastic and metal, the researchers are tapping into a more sustainable future where the materials we use don’t leave harmful footprints on the planet. Imagine a world where the precision required for the most advanced technologies is achieved using natural, biodegradable resources instead of synthetic ones.

In the coming years, the McGill team plans to expand their work, exploring other natural materials that could serve as even more effective micro-dispense tips. They hope to find other organic structures with greater strength or finer resolution. Additionally, they plan to further investigate how 3D necroprinting could be used in sustainable manufacturing and biomedical research, particularly in the creation of more environmentally friendly products.

Why This Research Matters

At its core, this research represents a paradigm shift. It’s not just about replicating nature—it’s about working with nature, using its inherent beauty and ingenuity to solve complex human problems. As we face mounting environmental challenges, this approach could prove to be a game-changer, offering sustainable, low-cost alternatives to the current technologies that are both resource-intensive and polluting.

The potential applications for this bio-nozzle are wide-ranging. In manufacturing, it could lead to more eco-friendly production methods that rely on renewable resources rather than non-biodegradable materials. In the biomedical field, it could offer new tools for tissue engineering and cell growth, advancing research in regenerative medicine. And in the world of 3D printing, it could democratize access to high-precision printing technology by offering a more affordable and sustainable solution.

By looking to the natural world for inspiration, McGill’s researchers have not only uncovered an innovative solution for 3D printing—they’ve also shown us the power of nature as a partner in technological progress. This research is a reminder that, often, the best solutions are the ones that have been right in front of us all along.

More information: Justin Puma et al, 3D necroprinting: Leveraging biotic material as the nozzle for 3D printing, Science Advances (2025). DOI: 10.1126/sciadv.adw9953