It started with a kitchen miracle: a pan so slick nothing could cling to it—not scrambled eggs, not melted cheese, not seared steak. For decades, Teflon and its cousins brought the promise of effortless cooking and stain-free living. Behind the gleam of every nonstick surface, however, lay a darker truth—one that would take decades to emerge.

These miracle substances belong to a vast family known as PFAS—per- and polyfluoroalkyl substances. Their molecular structure, marked by powerful carbon-fluorine bonds, is what grants them their fabled resistance to grease, water, and stains. But this same bond, so impervious to heat and time, also makes PFAS frighteningly persistent in the environment. They do not break down. They do not wash away. They accumulate.

And as research mounted, so did alarm bells. Traces of PFAS were found in blood, breast milk, soil, water—even in Arctic wildlife. Links to serious health issues followed: cancers, birth defects, immune disruption. Scientists and regulators began sounding the alarm, calling these synthetic compounds what they truly are: forever chemicals.

Searching for an Exit from a Chemical Trap

For engineers and materials scientists, the rise of PFAS created a paradox. These chemicals were nearly perfect in their function—slippery, durable, stain-resistant. But now the very characteristics that made them desirable had turned toxic. And the central question loomed: could we ever replace them?

For years, researchers tried to engineer substitutes—safe materials that could offer similar performance without the environmental and biological cost. But every path forward seemed blocked. Repelling water was simple. Repelling oil, grease, and sticky residues? That was far harder. Despite endless experimentation, the alternatives couldn’t match the performance of PFAS. Scientists had hit a performance ceiling.

But a new material, developed at the University of Toronto’s Faculty of Applied Science & Engineering, might be the first to break through that barrier—and it does so with an imaginative twist on chemistry and an inspiring commitment to sustainability.

A New Kind of Surface: Born in the DREAM Lab

Inside the Durable Repellent Engineered Advanced Materials (DREAM) Laboratory, Professor Kevin Golovin and his team have long been obsessed with a question that haunts modern material science: how do we make materials that repel both water and oil—without relying on dangerous chemistries?

Their breakthrough lies in a substance known as polydimethylsiloxane, or PDMS. Often sold commercially as silicone, PDMS is already widely used in applications ranging from kitchen utensils to biomedical implants. It is flexible, stable, and generally considered biocompatible. But when it comes to oil and grease, PDMS has always fallen short—until now.

Doctoral student Samuel Au, a key member of Golovin’s team, took this challenge to heart. And instead of mimicking what PFAS did, he decided to rethink how repellency could be built from the molecular level upward.

The Art of Nanoscale Fletching

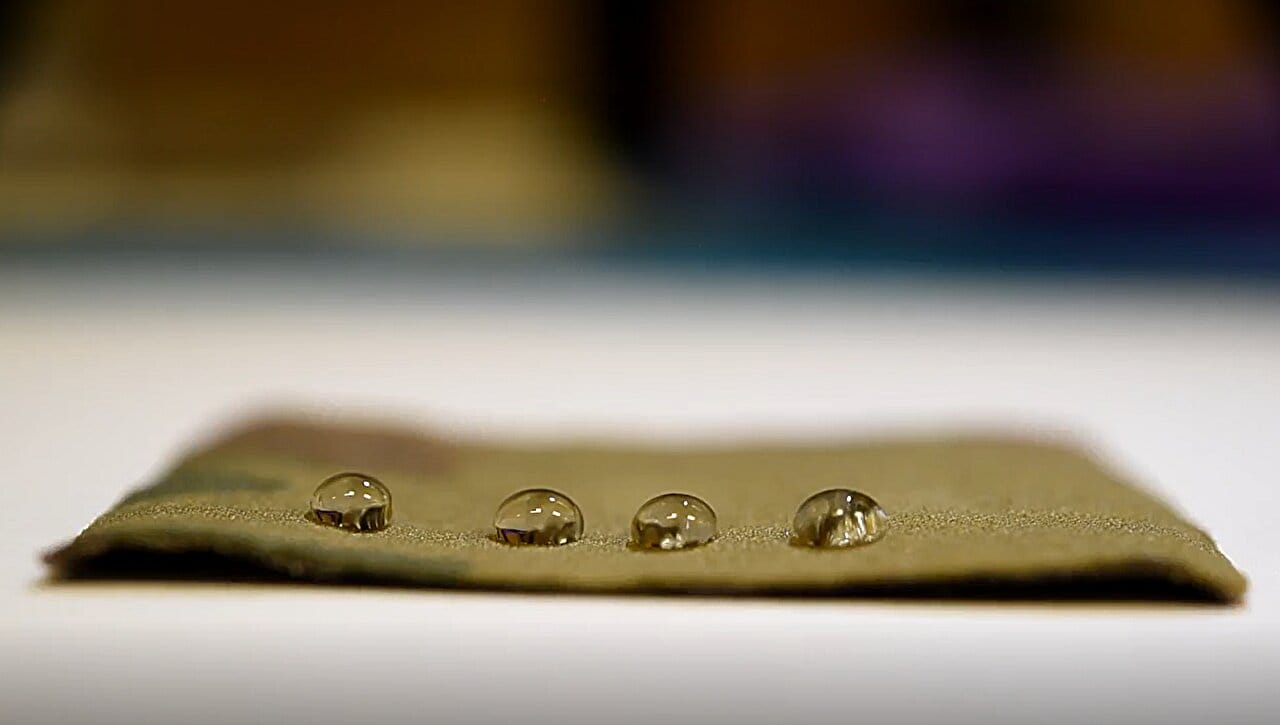

Au’s innovation is a technique the team calls “nanoscale fletching”—a name borrowed from the feathered tail of an arrow. At the molecular scale, the new material looks like a microscopic forest: thousands of tiny PDMS bristles anchored onto a surface, each enhanced with just a whisper of PFAS—specifically, the smallest PFAS molecule possible.

“We essentially decorated the ends of PDMS chains with the shortest fluorinated molecule—a single carbon with three fluorines,” Au explained. “Only about seven of these were bonded to each bristle. If you could zoom in far enough, the result would resemble the back of an arrow—feathered for performance.”

It’s an elegant solution: by using the least amount of fluorinated chemistry needed for function, the team reduced risk without sacrificing performance. The end result is a hybrid surface that achieves oil repellency comparable to commercial PFAS coatings, while containing only a fraction of the chemicals that make PFAS dangerous.

When tested on fabric, the material resisted oils with a grade of 6 on the American Association of Textile Chemists and Colorists scale—roughly equivalent to industry-standard coatings. It’s a performance level that many previously thought was impossible without long-chain PFAS.

A Safer Chemistry—By Design

The nuance in this breakthrough lies in the type of PFAS used. The research team deliberately avoided long-chain PFAS—the variants known to bioaccumulate and trigger widespread health concerns. Instead, they employed a minimalist molecular fragment: a single carbon-fluorine unit, just enough to improve performance without posing the same environmental threat.

Golovin acknowledges that their solution still uses PFAS—but emphasizes its minimalism and safety profile. “What we’ve seen in the literature, and even in emerging regulations, is that the shortest-chain PFAS are far less harmful than the long-chain ones. Our material achieves high performance with vastly reduced risk,” he said.

This approach reflects a growing movement in chemistry and materials engineering: to design safer materials not by eliminating all performance chemicals, but by understanding their behavior deeply enough to use them precisely, sparingly, and safely.

Rethinking What “Nonstick” Can Mean

The implications of this development go well beyond cookware. Nonstick coatings are everywhere: in waterproof jackets, takeout containers, upholstery, and even cosmetics. In each of these domains, PFAS has lingered for decades, waiting for a viable replacement.

The Toronto team’s new material could serve as a platform for a generation of repellent surfaces—ones that don’t leach toxins into groundwater or accumulate in the food chain. And because the coating can be applied to textiles, plastics, and other surfaces, the possibilities for application are expansive.

Of course, this isn’t the end of the journey. Golovin is clear-eyed about the road ahead. “The holy grail of this field would be a material that outperforms Teflon with no PFAS at all,” he said. “We’re not there yet—but this is a step in the right direction.”

Between Performance and Responsibility

In today’s world, material science can no longer afford to focus solely on function. The age of innovation without consequence is over. As communities demand greener products, and regulators push for accountability, research like this takes on new urgency.

The University of Toronto team has shown that it’s possible to reconcile performance with responsibility—to develop a coating that meets the demands of modern life while respecting the delicate web of environmental health.

Their work underscores a critical message: innovation is no longer just about making better products. It’s about imagining a better future.

From Lab Bench to Market

Though the research remains in early stages, the team is actively seeking industry partners to scale the technology. They envision licensing the nanoscale fletching process to manufacturers of cookware, apparel, packaging, and beyond.

But even as they move toward commercialization, the research team continues its pursuit of something bolder: a world without PFAS at all.

With each new prototype, they come closer to proving that humans can design materials that serve our needs—without poisoning the planet.

Redefining What Lasts

The legacy of PFAS is a reminder that some inventions outlive their usefulness. What was once a marvel became a menace. But from that reckoning, something new is being born—an era of smarter, safer chemistry, driven by imagination and conscience.

The future of nonstick may no longer be defined by what lasts forever, but by what lasts long enough—and leaves no harmful trace behind.

Reference: Samuel Au et al, Nanoscale fletching of liquid-like polydimethylsiloxane with single perfluorocarbons enables sustainable oil-repellency, Nature Communications (2025). DOI: 10.1038/s41467-025-62119-9