Natural gas has always been a quiet giant of the energy world. It burns in power plants and home stoves, its flames fueling modern life while releasing greenhouse gases that complicate our future. Beneath its usefulness lies an untapped promise: methane, ethane, and propane are everywhere, abundant and inexpensive. Yet for decades, chemists have struggled to persuade these stubborn molecules to do anything other than burn. Their stability makes them resistant to transformation, blocking the path to cleaner, more circular chemical manufacturing.

That long-standing barrier has now cracked open. At the University of Santiago de Compostela, a team led by Martín Fañanás at the Center for Research in Biological Chemistry and Molecular Materials has developed a method that reimagines what natural gas can become. Their work, published in Science Advances, reveals how some of the world’s simplest hydrocarbons can be turned into powerful molecular “building blocks” for producing high-value chemicals, including pharmaceuticals. It is not just a technical advance but a shift in how we might someday build the materials that underpin modern society.

A Breakthrough Born From a Simple Beginning

The team’s achievement rests on a moment that would have once sounded almost impossible: for the first time, they synthesized a bioactive compound—dimestrol, a non-steroidal estrogen used in hormone therapy—directly from methane itself. A molecule as small and inert as methane is rarely trusted to do anything other than combust. But here, it becomes the starting point for crafting a complex, highly specific pharmaceutical ingredient.

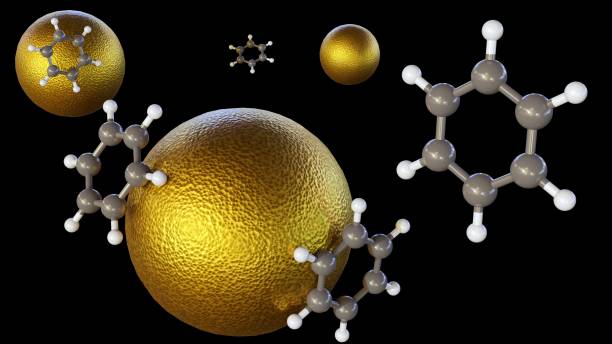

To make this leap, the researchers relied on a transformation called allylation. In essence, they attach a tiny chemical “handle” to the gas molecule, a small allyl group that behaves like a docking point. Once this handle is in place, chemists can build outward from it, adding pieces step by step until simple gas becomes an intricate, functional compound. But mastering this reaction was far from straightforward. Previous catalytic systems often spiraled into chaos, generating unwanted chlorination byproducts that ruined the process.

Overcoming that obstacle required a catalyst unlike anything that came before.

Inside the Catalyst That Changed the Story

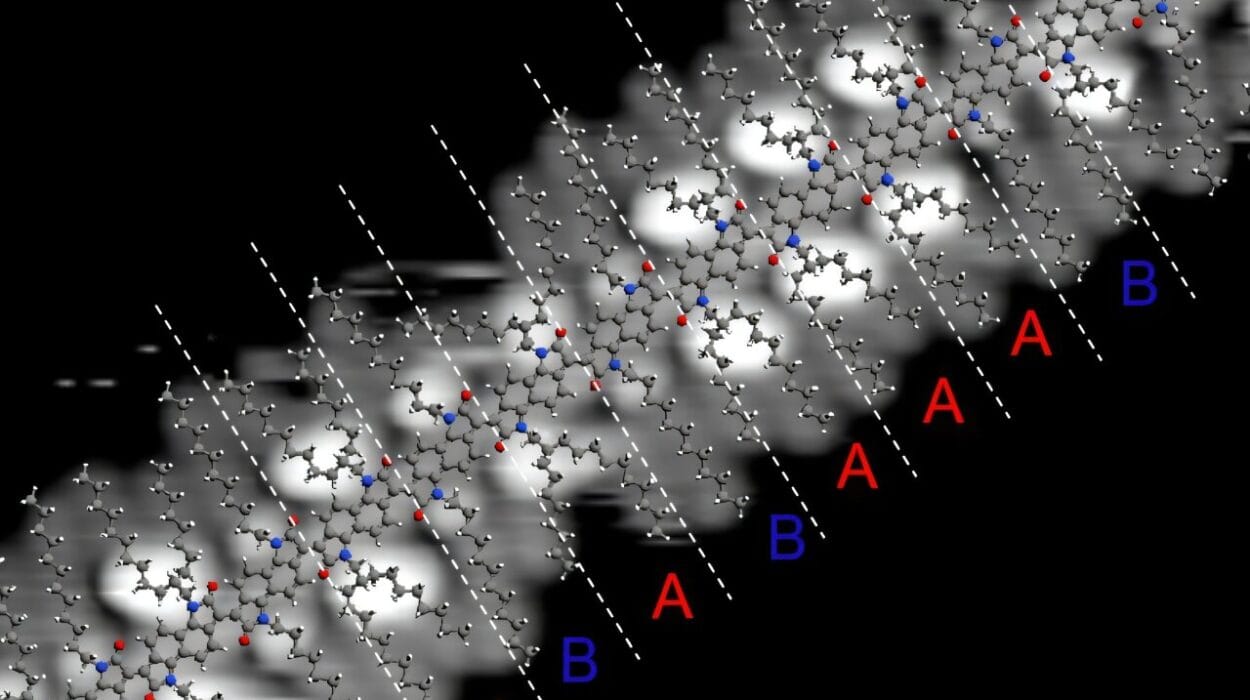

The CiQUS team engineered a catalyst that behaves almost like a guardian of the reaction, guiding it along the right path while protecting it from missteps. As Prof. Fañanás explains, “The core of this breakthrough lies in designing a catalyst based on a tetrachloroferrate anion stabilized by collidinium cations, which effectively modulates the reactivity of the radical species generated in the reaction medium.”

The secret lies in the architecture surrounding the iron atom at the catalyst’s heart. “The formation of an intricate network of hydrogen bonds around the iron atom sustains the photocatalytic reactivity required to activate the alkane, while simultaneously suppressing the catalyst’s tendency to undergo competing chlorination reactions. This creates an optimal environment for the selective allylation reaction to proceed.”

That carefully constructed molecular environment prevents the reaction from slipping into unwanted side routes. Instead, it channels the energy precisely where it needs to go, producing controlled radical species capable of activating the gas molecules without destroying them.

The elegance of the design is matched by its practicality. The metal at the center is iron—cheap, abundant, and far less toxic than the precious metals often used in advanced catalysis. The reaction runs at mild temperature and pressure. It is powered by LED light. In a field often criticized for high environmental costs, this approach stands out as remarkably sustainable.

Two New Pathways, One Larger Vision

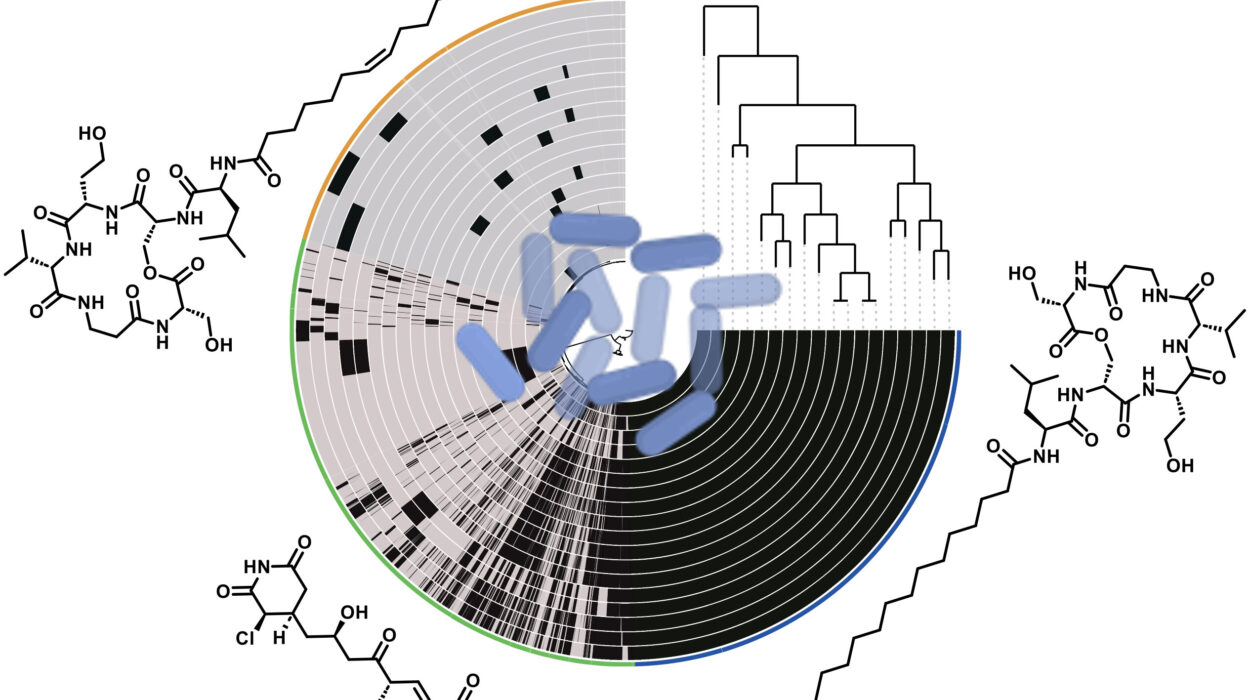

The allylation method is not the team’s only recent triumph. In a complementary study published in Cell Reports Physical Science, the researchers developed a way to directly couple natural gas components with acid chlorides, producing industrially relevant ketones in a single step. This reaction, too, relies on photocatalysis, showing how the same vision—activating simple gases with light and carefully designed catalysts—can lead to multiple new chemical pathways.

Together, the studies highlight a deeper transformation. By learning how to convert methane, ethane, and propane into versatile intermediates, the team is unlocking a toolbox for the chemical industry. Instead of depending on conventional petrochemical feedstocks, manufacturers could begin with gas molecules that are plentiful and inexpensive. They could craft pharmaceuticals, specialty chemicals, and everyday materials without leaning as heavily on fossil-fuel refining.

This shift aligns with a broader goal: moving toward a more sustainable, circular chemical economy where abundant raw materials are used efficiently, precisely, and with minimal environmental cost.

Why This Breakthrough Matters

The implications of this work stretch far beyond a single molecule or reaction. The world relies on chemicals made from petroleum, yet the processes that create them are energy-intensive, polluting, and locked into rigid supply chains. Natural gas, while itself a fossil fuel, offers a cleaner-burning alternative, and its components—especially methane—are among the most abundant organic molecules on Earth. If those molecules can be upgraded directly into high-value products with minimal energy input, the chemical industry gains a powerful pathway to reduce environmental impact while maintaining production of essential goods.

By transforming methane into dimestrol, the CiQUS team has demonstrated something profound: even the simplest hydrocarbon can be shaped into something extraordinarily complex. Their method shows how sustainable catalysts, gentle conditions, and clever molecular engineering can converge to rewrite what is chemically possible. It is a reminder that big changes often begin with the smallest building blocks, and that rethinking how we use those blocks can redefine an entire field.

Most importantly, the work signals that the tools for a more circular, lower-emission chemical economy already exist in emerging form. As CiQUS continues to innovate—supported by its CIGUS accreditation, which recognizes the excellence and impact of its research—the story of natural gas may shift from one of combustion to one of creation. In that transformation lies the promise of a cleaner, smarter, and more flexible industrial future.

More information: Andrés M. Álvarez-Constantino et al, Attenuated LMCT photocatalysis enables C─H allylation of methane and other gaseous alkanes, Science Advances (2025). DOI: 10.1126/sciadv.aea0783

Akshay M. Nair et al, Upscaling of gaseous alkanes into large-volume commodity chemicals via photocatalytic acylation, Cell Reports Physical Science (2025). DOI: 10.1016/j.xcrp.2025.102912