The story of a breakthrough often begins with a familiar image, something so ordinary that it hides in plain sight. For the University of Toronto researchers behind a powerful new metal composite, that image was reinforced concrete. The kind used in bridges, towers, and sidewalks. The kind that relies on steel rebar woven through cement to hold the world together.

It was this everyday architecture that inspired a material unlike anything seen before. Light enough to rival aluminum and strong enough to withstand temperatures of 500 Celsius without losing its backbone, the discovery is now detailed in Nature Communications. It is built from metallic alloys, nanoscale precipitates, and a microscopic structure that behaves like concrete—only far stronger and far lighter.

This unlikely pairing of ideas may soon reshape the future of aerospace and other industries where weight, heat, and strength battle for control.

When Aircraft Dream of Shedding Weight

In aviation, every gram has consequences. Aircraft designers know that lighter materials mean more fuel efficiency, longer range, and more possibilities. Aluminum has long been the hero of the skies, offering a weight advantage over steel. Yet even aluminum has a fatal flaw.

“Until now, aluminum components have suffered from performance degradation at high temperatures,” says Chenwei Shao, a research associate in Yu Zou’s lab and lead author of the new study. “Basically, the hotter they get, the softer they get, rendering them unsuitable for many applications.”

It is a simple truth with enormous implications. Engines, turbines, and aircraft skins face temperatures that turn aluminum into something fragile. In a world obsessed with efficiency, the search for a metal that stays strong while staying light has grown urgent.

And that urgency fueled a daring idea.

Reimagining Metal Through Microscopic Architecture

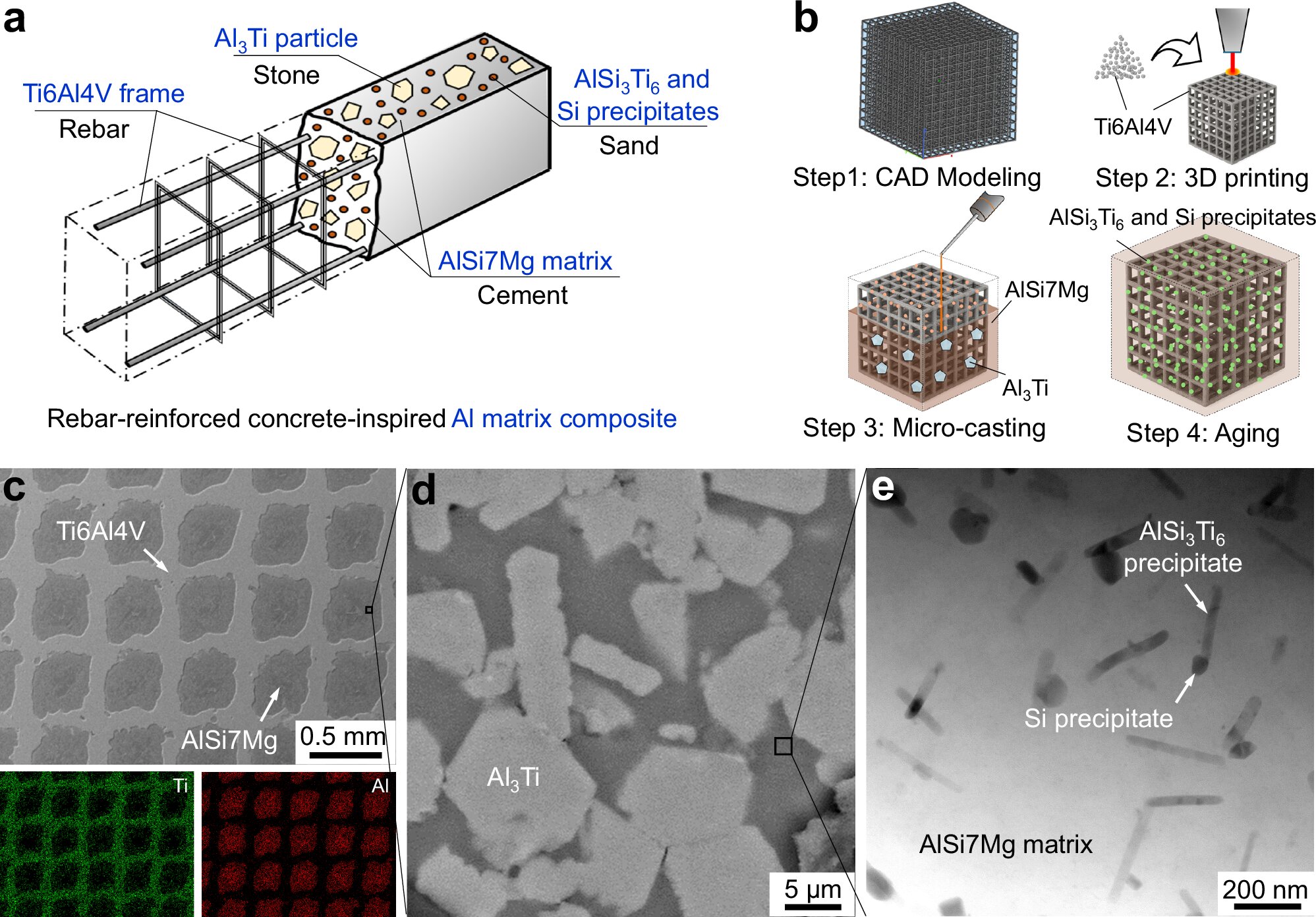

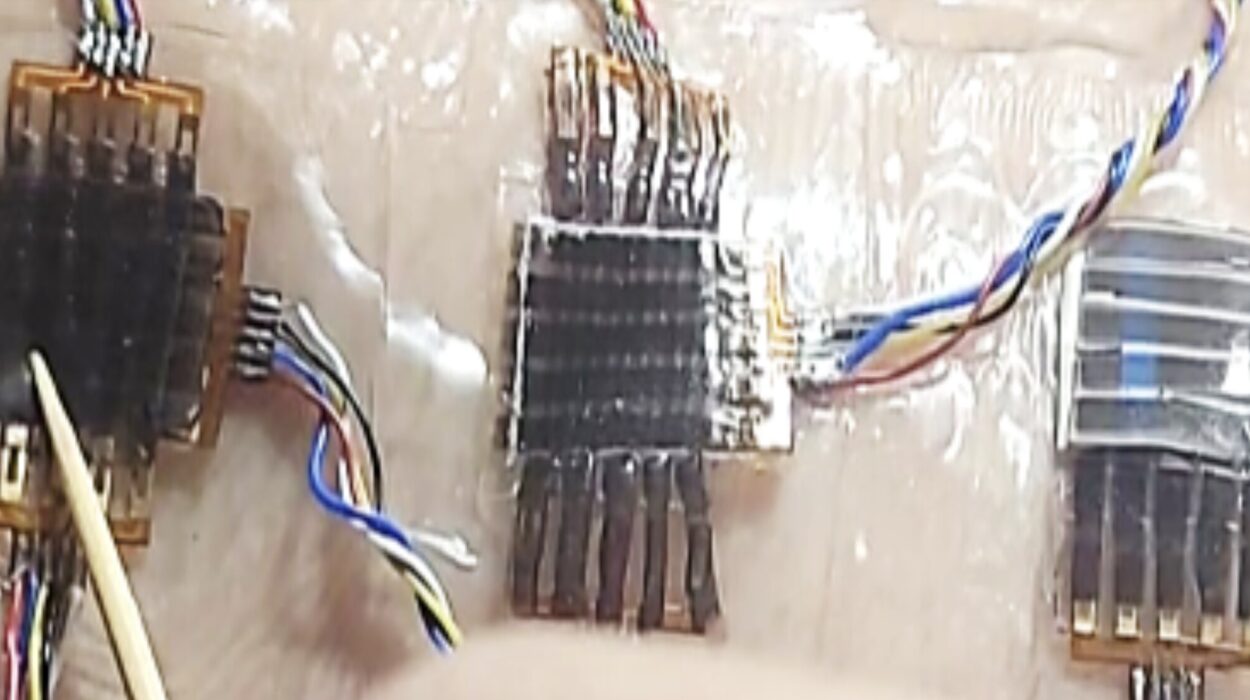

The team set out to recreate the structural magic of concrete, but in a world thousands of times smaller. They envisioned a cage-like framework—just like steel rebar—wrapped inside a solid matrix. But instead of cranes and scaffolds, they built their structure using lasers and metal powders.

“Steel rebar is widely used in the construction industry to improve the structural strength of concrete in buildings and other large structures,” says senior author Yu Zou. “New techniques such as additive manufacturing, also known as 3D metal printing, have now enabled us to mimic this structure in the form of a metal matrix composite. This approach gives us new materials with properties we’ve never seen before.”

Layer by layer, the team created ultra-thin titanium alloy struts.

“In our material, the ‘rebar’ is a mesh made of titanium alloy struts,” Shao explains. “Because we use a form of additive manufacturing in which we fire lasers at metal powders to heat them into solid metal, we can make this mesh any size we want. The struts can be as small as 0.2 millimeters in diameter.”

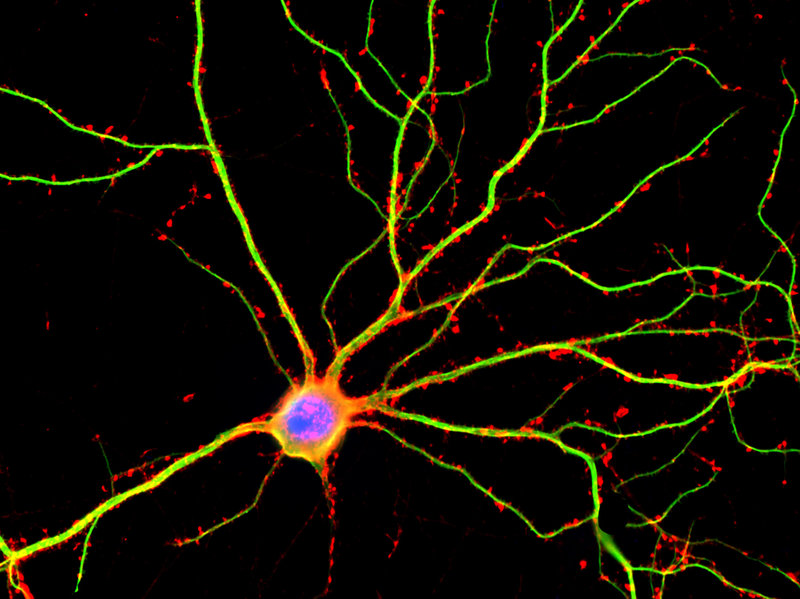

The microscopic gaps between those struts became the next frontier. The researchers filled them using a method called micro-casting, pouring in a blend of aluminum, silicon, and magnesium that hardened into a strong, uniform matrix. They seeded this matrix with micrometer-sized alumina particles and silicon nanoprecipitates—tiny structural reinforcements that behave like gravel in concrete.

The result was a complex internal landscape: titanium “rebar” surrounded by a composite “cement” toughened with nanoscale grit. Metal, reimagined through a builder’s logic and a physicist’s precision.

A Metal That Refuses to Surrender to Heat

Once the material had been built, the true test began. The researchers subjected it to extreme temperatures and pressures, pushing it far beyond what typical aluminum composites could endure.

“At room temperature, the highest yield strength we got was around 700 megapascals; a typical aluminum matrix would be more like 100 to 150 megapascals,” says Shao. “But where it really shines is at high temperature. At 500 Celsius, it has a yield strength of 300 to 400 megapascals, compared to about five megapascals for a traditional aluminum matrix.

“In fact, this new metal composite performs about as well as medium-range steels, but at only about one-third the weight.”

The numbers speak for themselves. What collapses in aluminum at high temperatures remains remarkably intact here. Something inside the material was keeping it strong. But what?

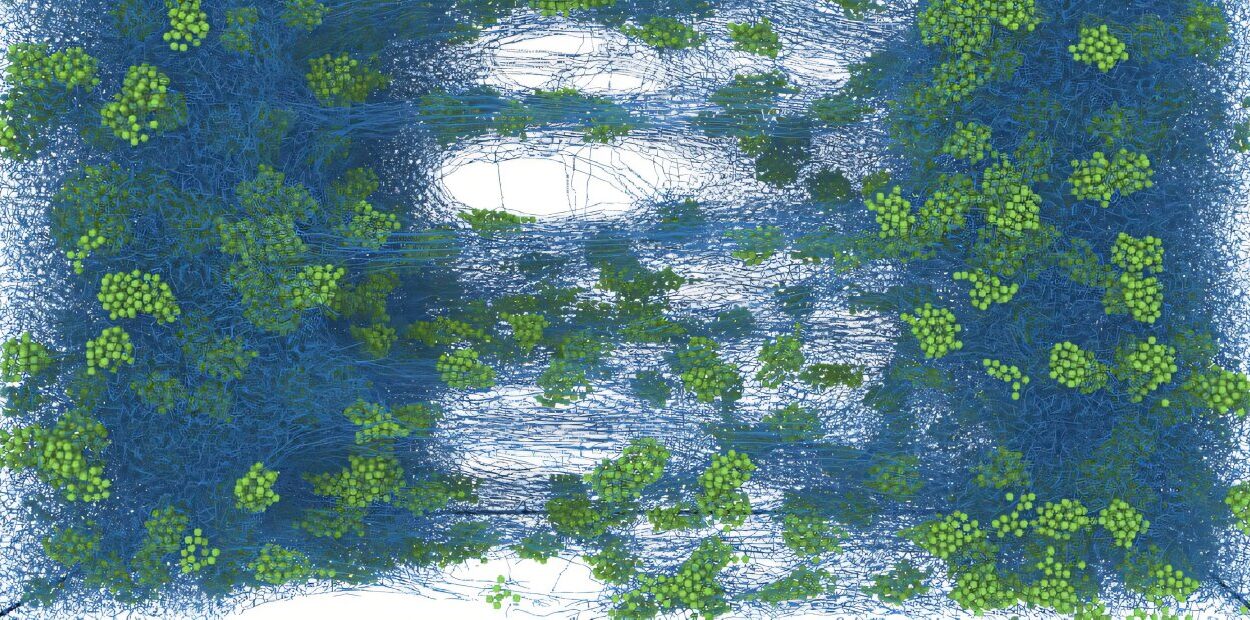

To find out, the researchers built detailed computer simulations of how the metal behaves when pushed to extremes.

“What we found was that at high temperatures, this composite material deforms via a different mechanism than most metals,” says study co-author Huicong Chen, who led the computer simulations. “We called this new mechanism ‘enhanced twinning,’ and it enables the material to maintain much of its strength, even when it gets very hot.”

In metals, deformation is often the enemy. But in this case, a new mode of deformation helped preserve strength rather than destroy it. The metal didn’t merely resist heat—it adapted to it.

Where Discovery Meets Possibility

For now, the new composite is a triumph of scientific creativity rather than a commercial product. Manufacturing it is expensive. Scaling it is complex. But the path forward is clear enough for Zou to see its future potential.

“We wouldn’t have been able to make this material any other way,” he says. “It’s true that it still costs a lot to create materials like this at scale, but there are some applications where the high performance will be worth it. And as more companies invest in advanced manufacturing technologies, we will eventually see the cost come down.

“We think this is an exciting step forward toward stronger, lighter and more efficient vehicles.”

Why This Research Matters

This new composite material is more than an engineering accomplishment; it represents a shift in how we think about metals. By borrowing an idea from concrete and shrinking it to the microscopic scale, the researchers created a material that breaks long-standing trade-offs. It resists heat without losing strength. It offers steel-like performance without steel’s weight. It reveals a new deformation mechanism that could inspire entirely new classes of materials.

In fields like aerospace—where weight, heat, and durability determine what is possible—this discovery opens doors that did not previously exist. Every lighter, stronger component contributes to more fuel-efficient aircraft and more capable vehicles. And every advancement in additive manufacturing brings us closer to designing materials that were once impossible.

At its heart, this breakthrough is a reminder that innovation often begins with reimagining something familiar. In this case, the world of towering buildings and everyday concrete has quietly guided the creation of a metal built for the skies.

More information: Chenwei Shao et al, Achieving improved mechanical performance in aluminum matrix composites with rebar-reinforced concrete-inspired structures, Nature Communications (2025). DOI: 10.1038/s41467-025-65234-9