In a quiet laboratory in São Paulo, a team of researchers watched an unlikely fusion take shape: native bee honey swirling with fragments of cocoa bean shells, trembling gently under the invisible force of sound. It was the kind of scene that feels almost like a kitchen experiment, except that what happened in that small pot has now made the cover of ACS Sustainable Chemistry & Engineering. Their creation can be eaten straight from the jar or woven into foods and cosmetics, but its story reaches far beyond flavor. It begins with a deceptively simple question: what happens when you use honey as a solvent and sound as a tool?

Where Honey Meets Cocoa and Science Takes Over

At the State University of Campinas (UNICAMP), researchers were searching for a way to turn plant residues into something valuable without relying on harsh chemicals or wasteful energy. Cocoa bean shells—often discarded—became their target. And honey from native bees, a product already prized but fragile, became their solvent of choice. The partnership between these two ingredients was unusual, but that was exactly the point.

To bring them together, the team used ultrasound-assisted extraction, a process that sounds almost whimsical but is anything but. A slender metal probe, “visually similar to a metal pen,” was placed into the mixture. As the probe pulsed, sound waves traveled through the pot, shaking the shells at a microscopic level and encouraging their compounds to leap into the honey.

The magic in this method lies in the microbubbles created by the sound. They expand and collapse violently—imploding in tiny flashes of heat and pressure. In doing so, they break down the plant material far faster and more efficiently than traditional methods. For the researchers, this wasn’t just about efficiency. It was about reinventing extraction through green chemistry principles that minimize environmental impact.

Listening for Sustainability

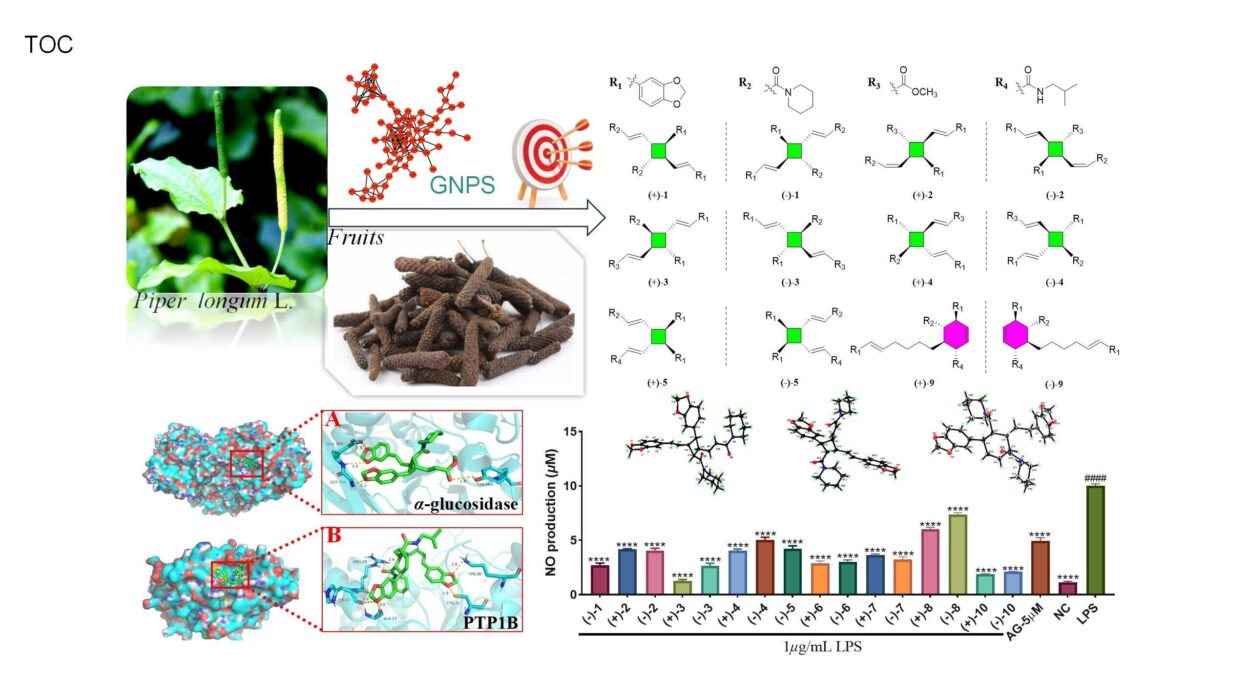

Sustainability was not a side note in this project; it was a benchmark. The team used Path2Green software, developed by a group led by Professor Mauricio Ariel Rostagno, who also supervised the work. The tool evaluates processes using 12 principles of green chemistry, examining factors like transportation, post-treatment, purification, and final application.

One detail proved especially decisive: the solvent was edible, local, and ready to use. No additional processing. No complex purification. No chemical hazards. Honey itself became proof that sustainability can be both simple and elegant.

In the end, the product scored +0.118 on a scale from -1 to +1—a modest number, perhaps, but one that reflects a carefully optimized, environmentally aligned process built on materials that might otherwise be overlooked.

Rostagno sees real-world potential written all over it. “We believe that with a device like this, in a cooperative or small business that already works with both cocoa and native bee honey, it’d be possible to increase the portfolio with a value-added product, including for haute cuisine,” he suggests. For communities working with these raw materials, the idea of a new, gourmet-ready product—created sustainably—offers more than scientific novelty. It offers opportunity.

The Sound That Silences Microbes

As the team celebrated what they had created, another question emerged: what had the ultrasound done to the honey itself?

Honey from native bees is famously delicate. Unlike the honey commonly found on shelves—produced by European bees—it cannot simply sit at room temperature. It must be refrigerated, matured, dehumidified, or pasteurized to avoid degradation. For producers, this fragility adds both cost and complication.

But during ultrasound extraction, something interesting happens. The same forces that break down plant cell walls also rattle the walls of microorganisms. If those microorganisms break apart, the honey becomes more stable. This possibility is now driving the team’s next steps.

“Honey from native bees usually needs to be refrigerated, matured, dehumidified, or pasteurized, unlike honey from European bees, which can be stored at room temperature,” Rostagno explains. “We suspect that, simply by being exposed to ultrasound, the microorganisms contained in the honey are eliminated, increasing the stability and shelf life of the product.”

To many researchers, the idea that ultrasonic vibrations could extend the life of such a delicate ingredient is exciting. If future studies confirm this effect, ultrasound could become not just an extraction tool but a preservation method—one especially suited to small producers without access to large-scale pasteurization equipment.

A Future Built on Buzzing Possibilities

The work at UNICAMP is only at its beginning. The researchers already have plans to explore new uses for ultrasound-assisted extraction with native bee honey as the primary solvent. The cocoa bean shells were just the first test. They want to evaluate other plant residues—other forgotten materials that might reveal unexpected flavors, nutrients, or useful compounds when gently persuaded by sound waves.

If the early results are any indication, this method could unlock a new category of sustainable products made from ingredients that are local, edible, and environmentally friendly. Each new application would deepen the partnership between traditional foods and cutting-edge chemistry, bringing science directly into the hands of producers and artisans.

Why This Research Matters

This project stands at a crossroads between science, sustainability, culture, and practicality. It transforms agricultural byproducts into resources rather than waste. It gives honey—a culturally significant product of native bees—a new role as both solvent and preservative. It offers small businesses a pathway to value-added products without requiring heavy machinery or complex chemicals. And it demonstrates that innovation can grow not only from advanced technology, but from the thoughtful use of what nature already provides.

It is a reminder that sometimes the most powerful scientific tools are the ones that make processes simpler, cleaner, and more accessible. Honey, cocoa shells, and the hum of ultrasound may seem like an unlikely trio, but together they reveal a truth at the heart of green chemistry: nature gives us everything we need, if we learn how to ask gently.

What began as a buzzing probe in a pot has become a promising new frontier for sustainable food and cosmetic ingredients. And as researchers continue to listen closely to what sound can coax from the natural world, even more possibilities are likely to unfold.

More information: Felipe Sanchez Bragagnolo et al, Stingless Bee Honeys As Natural and Edible Extraction Solvents: An Intensified Approach to Cocoa Bean Shell Valorization, ACS Sustainable Chemistry & Engineering (2025). DOI: 10.1021/acssuschemeng.5c04842