Fuel cells have long been hailed as one of the most promising clean-energy solutions of our time. Instead of burning fuel, they quietly convert chemical energy into electricity through elegant chemical reactions. Among them, direct methanol fuel cells (DMFCs) stand out for their potential to power vehicles, large electronics, and other portable systems. They run on methanol — a simple alcohol that’s easy to store, transport, and refuel.

Yet there’s a stubborn flaw that has kept DMFCs from becoming the go-to power source: over time, their performance drops, sometimes dramatically. The culprit lies at the microscopic heart of the cell — the electrocatalytic surfaces that make the fuel-to-electricity reaction possible. As the cell operates, these surfaces become “poisoned” by byproducts of the reaction, losing their effectiveness and reducing the cell’s power output.

Scientists have known for years that one way to revive these surfaces is to modulate the voltage — applying just the right changes to “clean” the catalyst and restore performance. But finding the perfect voltage patterns in real time, while the cell is running, is a task too complex for any human operator to manage efficiently.

Enter the Alpha-Fuel-Cell

That’s where a team at the Massachusetts Institute of Technology (MIT) stepped in, armed with artificial intelligence. They developed a machine learning system called Alpha-Fuel-Cell, described in a recent Nature Energy paper, that can watch a fuel cell as it operates, assess the condition of its catalyst in real time, and automatically adjust the voltage for optimal performance.

The results are nothing short of remarkable: the system boosted the average power output of DMFCs by 153% compared to traditional manual control.

“Fuel cells slowly lose power as they run, and it’s hard for humans to keep adjusting the controls to get the most out of them,” said Ju Li, senior author of the study. “We asked a simple question: could an AI system watch the fuel cell in real time and keep it operating at its optimal spot, the way cruise control keeps your car at a steady speed?”

How AI Learns to Heal a Fuel Cell

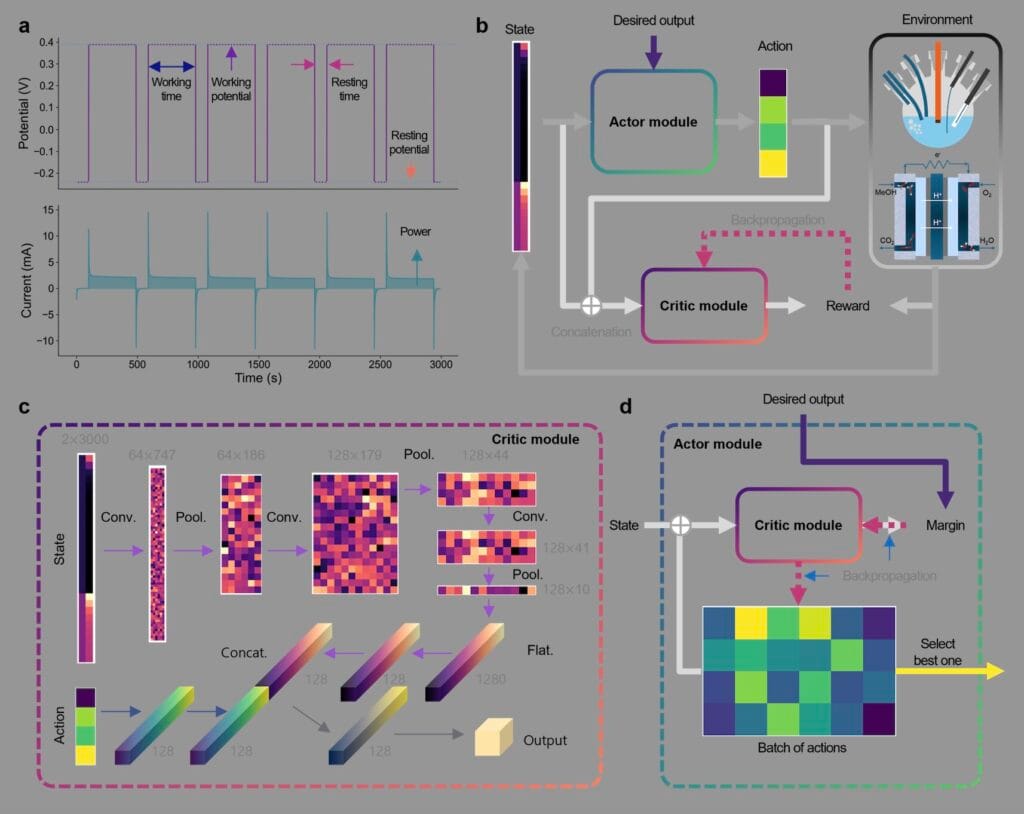

The Alpha-Fuel-Cell system relies on a reinforcement learning framework known as an actor-critic architecture. In simple terms, the “actor” decides what actions to take — in this case, how to tweak the voltage — while the “critic” evaluates how good those actions are, based on the fuel cell’s condition.

To monitor the cell’s state, the critic uses a convolutional neural network (CNN), a technology more often seen in image recognition, but here applied to raw electrical data. By feeding it the trajectories of current and voltage over time, the CNN can recognize subtle patterns that reveal whether the catalyst is clean, dirty, or somewhere in between.

Alongside the state branch is the “action branch,” a standard feedforward neural network that predicts the outcomes of different voltage changes. Together, these branches let the system learn through trial and error, adapting its decisions on the fly to keep the cell performing at its peak.

“Our controller is a real-time, goal-adaptive architecture that learns directly from experimental data, with no simulator in the loop,” explained Li. “Since building a high-quality simulator is extremely difficult for complex energy devices, this is a significant advantage.”

Learning Fast, Working Smarter

Remarkably, the Alpha-Fuel-Cell didn’t require years of training or massive datasets. It learned to optimize performance using just about 1,000 real-world voltage-time trajectories, collected over two weeks of laboratory testing. The system not only discovered when to make adjustments, but also identified moments when giving the cell a short “rest” would help it recover power more effectively — something even skilled human operators might miss.

In essence, the AI developed its own version of strategic pit stops, balancing productivity with long-term health of the catalyst. The result: sustained, high power output without costly over-engineering or complicated maintenance schedules.

From the Lab to the Real World

For now, Alpha-Fuel-Cell has been tested on single lab-scale DMFCs, but the MIT team is already working on scaling it up. The vision is to apply the same AI-driven approach to full-scale fuel cell stacks, the kind used in vehicles and portable power systems, while incorporating built-in safety protocols and lifetime optimization.

Even more exciting, the researchers believe the same strategy could work for batteries, CO₂ electrolysis systems, and other electrochemical devices that suffer from gradual performance degradation. If successful, this could lead to a new generation of self-optimizing clean energy systems — devices that don’t just run, but learn and heal themselves as they go.

“The system is the first demonstration of combining AI and energy devices for automatic catalyst self-healing,” said Li. “Any clean-energy device drifts and ages — the difference now is that we can teach it to recover on its own.”

A Glimpse of the Future

The implications of this work extend far beyond the lab bench. As the world races to replace fossil fuels with cleaner technologies, efficiency and longevity are key. AI tools like Alpha-Fuel-Cell promise to make every drop of methanol, every bit of battery charge, and every watt of renewable power go further.

It’s a vision of energy technology not as a static machine, but as a living, adaptive system — one that watches itself, learns from its own behavior, and keeps itself in top form. And in the fight against climate change, that’s the kind of intelligence we’ll need.

More information: Hongbin Xu et al, An actor–critic algorithm to maximize the power delivered from direct methanol fuel cells, Nature Energy (2025). DOI: 10.1038/s41560-025-01804-x.