From the fiery re-entry of spacecraft to the blistering roar of hypersonic vehicles slicing through the atmosphere, one challenge has remained constant: heat. The temperatures in these environments soar to levels that can melt most known materials. Traditional thermal insulation materials—those designed to block or manage heat—either crumble at extreme temperatures or are too bulky to be practical. A furnace wall or a spacecraft’s heat shield cannot simply be made endlessly thicker; weight and efficiency matter as much as protection.

The scientific community has long sought a material that could endure unimaginable heat without breaking down, all while staying thin, light, and adaptable. Now, researchers in China have unveiled a discovery that may finally answer this call.

The Carbon Nanotube Revolution

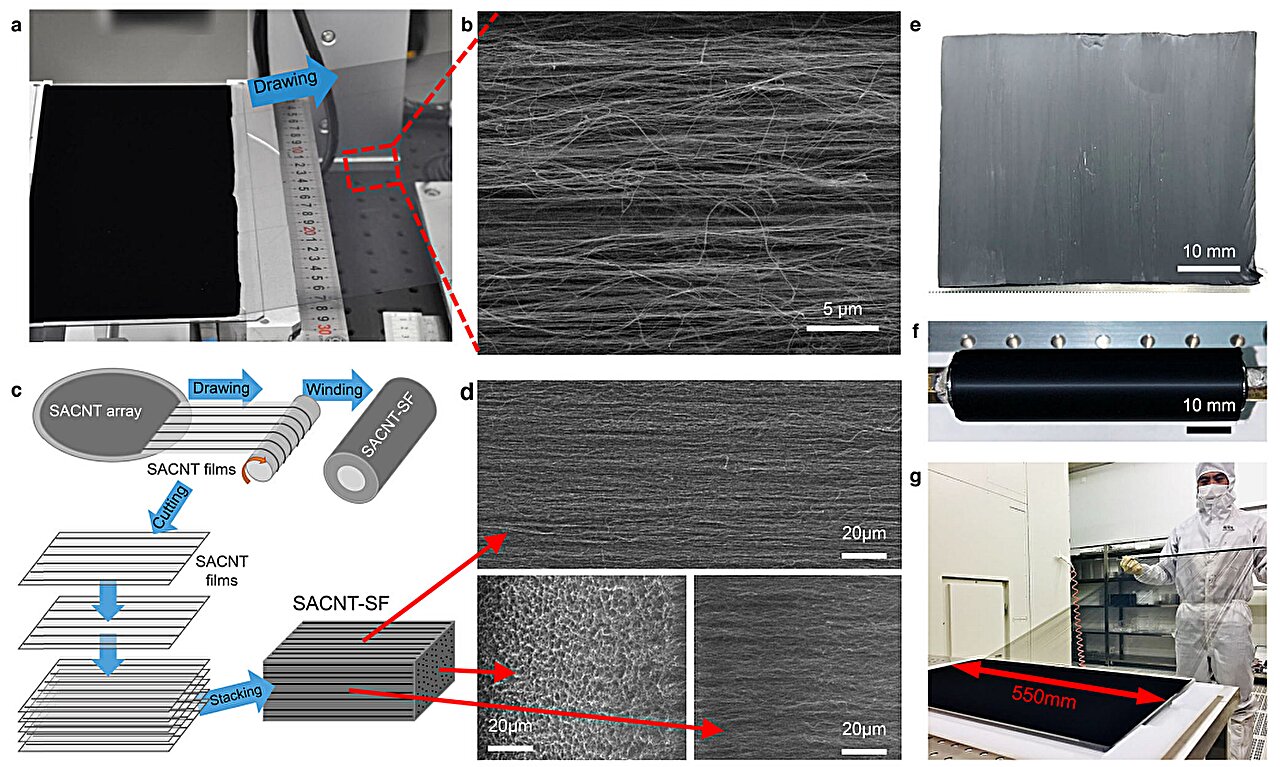

At the heart of this breakthrough lies a marvel of nanotechnology: carbon nanotubes. These are cylindrical structures, only a few nanometers wide, made entirely of carbon atoms. Despite their tiny size, they are famous for extraordinary strength, flexibility, and thermal properties. By carefully arranging these nanotubes into aligned, layered sheets, scientists at Tsinghua University have created something entirely new: super-aligned carbon nanotube films (SACNT-SF).

The concept may sound deceptively simple—stacking and winding thin films of nanotubes together—but the result is nothing short of revolutionary. These films act like an ultra-light, flexible shield against heat. Unlike conventional materials, which need bulk to resist thermal energy, SACNT-SF does more with less.

Defying the Limits of Heat

Most insulating materials begin to fail above 1,500°C. SACNT-SF, however, thrives where others collapse. It has been shown to withstand temperatures up to 2,600°C while maintaining its performance, making it the most effective thermal insulator known at such extremes. In laboratory tests, it demonstrated an effective thermal conductivity of 0.004 W m−1 K−1 at room temperature and 0.03 W m−1 K−1 at 2,600°C. These numbers may seem abstract, but they represent a staggering leap forward: SACNT-SF blocks heat better than any previously reported thermal insulation material.

The secret lies in its structure. The films are made up largely of empty space—microscopic gaps that reduce the pathways available for heat to move. At the same time, these gaps are so incredibly small that they prevent gas molecules from carrying heat across. It is a rare combination: low-density, high strength, and exceptional resistance to thermal transfer.

Strength in Fire and Flexibility

A material is only useful if it can survive repeated stress. SACNT-SF has proven itself resilient, enduring countless cycles of heating and cooling without degradation. In controlled atmospheres like argon, it remains stable even at 3,000°C, far beyond what most metals or ceramics can endure.

Just as impressive is its physical form. Unlike thick ceramic blocks or fragile fibers, SACNT-SF is paper-thin, flexible, and can be bent around curved surfaces. Imagine wrapping a spacecraft’s complex heat shield with lightweight sheets instead of heavy, rigid tiles. Or picture delicate electronics shielded from intense heat without adding bulky layers. This versatility opens the door to entirely new designs in aerospace, energy, and industry.

Potential Applications Across Frontiers

The excitement around SACNT-SF is not limited to the laboratory. The potential applications are vast and transformative.

For aerospace, it could redefine the design of spacecraft re-entry systems and hypersonic vehicles, allowing them to endure extreme atmospheric friction with lighter, more efficient shielding. In energy, SACNT-SF could be used to line industrial furnaces and nuclear reactors, improving efficiency and safety while cutting material costs. Even in electronics, its thin and flexible nature means it could protect sensitive components from overheating without compromising design.

If widely adopted, this material could mark a turning point in how we build the machines that carry humanity deeper into the skies—and deeper into the energy-intensive industries that power our world.

The Challenge of Oxygen

Yet, like all great innovations, SACNT-SF comes with a challenge. Carbon, for all its resilience, has one weakness: it burns. In the presence of oxygen, the films begin to oxidize at temperatures above 500°C. In practical terms, this means SACNT-SF cannot yet function in open-air high-temperature environments like jet engines or unprotected spacecraft.

The research team at Tsinghua University is already tackling this issue. Their solution involves adding protective coatings to the films, creating a barrier against oxygen while preserving the material’s insulating properties. If successful, this approach could unlock SACNT-SF’s full potential for real-world applications.

The Promise of a New Era

Every so often, science achieves a breakthrough that redefines what is possible. SACNT-SF is one such moment. By merging nanotechnology with the age-old challenge of heat protection, researchers have crafted a material that could shape the future of aerospace, energy, and beyond.

This discovery also carries a poetic reminder: sometimes, the answer to the universe’s greatest challenges lies in the smallest of structures. Nanotubes, invisible to the naked eye, may one day shield humanity’s most daring explorations—from the first footsteps on distant planets to the next generation of machines that sustain life here on Earth.

The story of SACNT-SF is just beginning. For now, it represents a beacon of possibility, a symbol of how human ingenuity can transform the impossible into the practical. In the flames of 2,600°C, where most matter surrenders, this fragile-looking film stands strong. And with it, perhaps, humanity will venture further than ever before.

More information: Zi Yuan et al, Carbon Nanostructure–Enabled High‐Performance Thermal Insulation for Extreme‐Temperature Application, Advanced Functional Materials (2025). DOI: 10.1002/adfm.202514142