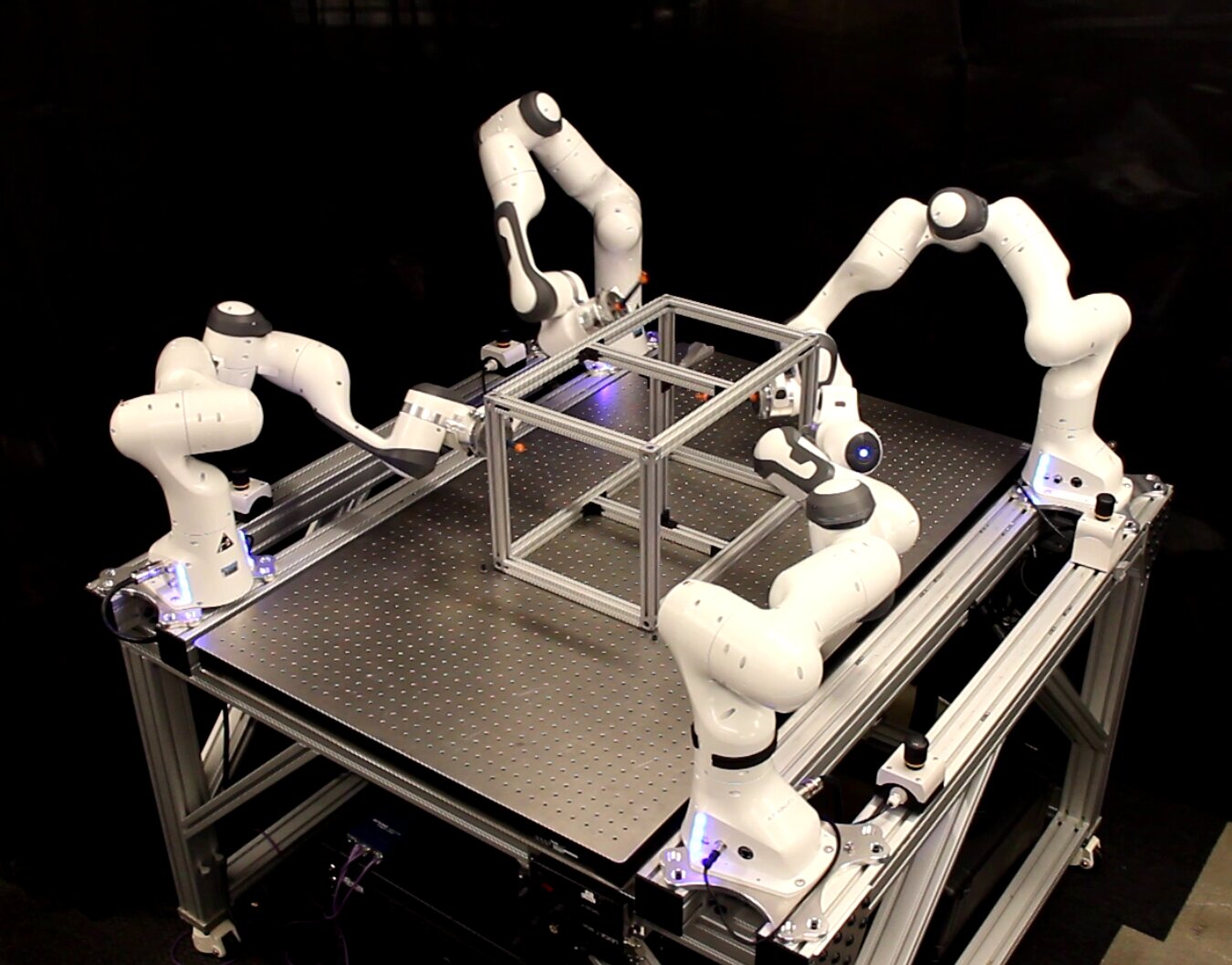

Factories have always been the heartbeat of human progress. From the first spinning looms of the Industrial Revolution to today’s gleaming assembly lines, they are where raw materials are transformed into the machines, tools, and electronics that shape our lives. But behind the precision of manufacturing lies a less glamorous truth: coordinating dozens of robotic arms in a shared, obstacle-filled space is incredibly difficult.

Until now, this planning work has been carried out by human experts, requiring hundreds of hours of tedious programming to ensure that no two robotic arms collide. It is painstaking, error-prone, and limits how quickly factories can adapt to new layouts or sudden changes.

Now, researchers from University College London (UCL), Google DeepMind, and Intrinsic have unveiled an innovation that could change all of this. Their system, called RoboBallet, allows multiple robotic arms to move together with a kind of fluid grace—almost like a dance—while planning their movements in seconds rather than days.

The Inspiration Behind RoboBallet

The name is more than just a metaphor. Ballet is about coordination, timing, and elegance. Dancers do not merely avoid colliding with each other; they anticipate one another’s movements, weaving a harmonious whole. This is precisely what RoboBallet aims to bring to industrial robotics.

As lead researcher Matthew Lai, a Ph.D. candidate at UCL and Google DeepMind, explains, “RoboBallet transforms industrial robotics into a choreographed dance, where each arm moves with precision, purpose, and awareness of its teammates. It’s not just about avoiding crashes; it’s about achieving harmony at scale.”

Factories, in this vision, are no longer crowded stages where clumsy machines struggle to avoid collisions. Instead, they become theaters of synchronized efficiency, with robots executing tasks in a carefully orchestrated rhythm.

The Technology That Makes It Possible

At the heart of RoboBallet lies a combination of two powerful strands of artificial intelligence: graph neural networks and reinforcement learning.

Graph neural networks (GNNs) are designed to process data structured like a network, with nodes and connections. This makes them perfect for reasoning about a factory floor, where robots, tools, and obstacles can be treated as interconnected points in a complex web. Instead of seeing the space as a chaotic mess, RoboBallet’s AI “brain” sees an organized map.

Reinforcement learning (RL), meanwhile, teaches the system through trial and error. The AI tries out different movement strategies, receives a “reward” when it completes tasks successfully, and learns to prefer strategies that maximize rewards. Over time, the system develops an intuition for efficient, collision-free motion.

After only a few days of training, RoboBallet could generate high-quality movement plans in mere seconds. Remarkably, it performed well even in layouts it had never encountered before. In one demonstration, the system successfully coordinated eight robotic arms across forty separate tasks, far surpassing what traditional planning systems could achieve.

Why This Matters for Industry

For manufacturers, RoboBallet represents more than just a technical curiosity. It could save enormous amounts of time, money, and energy. Right now, planning robotic movements in a factory requires hundreds of hours of specialist work. With RoboBallet, that process could be automated and completed instantly.

This flexibility is critical in modern production, where supply chains change quickly, and factories must adapt on the fly. If a robot malfunctions, or if the factory layout is altered, RoboBallet can re-plan the movements of the remaining robots in real time, ensuring production continues smoothly.

Associate Professor Alex Li of UCL Computer Science likens the problem to “solving a moving 3D puzzle, where every action must be perfectly timed and placed to avoid collisions.” RoboBallet, he explains, gives factories the power to solve these puzzles effortlessly.

Applications Across Industries

The potential uses are vast. Car manufacturers could deploy RoboBallet to streamline assembly lines where dozens of robotic arms perform welding, painting, and fastening. Electronics companies could use it to coordinate the delicate motions needed to assemble tiny circuit boards. Even construction firms might eventually use such systems to deploy teams of robots building houses side by side.

What makes RoboBallet especially exciting is its scalability. Traditional planning algorithms often fail when too many robots are involved, because the problem’s complexity grows exponentially. RoboBallet, however, doesn’t just memorize solutions—it learns general principles of coordination. This means it can scale up to larger teams of robots without breaking down.

A Glimpse Into the Future of Robotics

Right now, RoboBallet focuses on “reaching tasks,” where a robotic arm simply moves to a specific point—such as welding a seam or tightening a bolt. But the researchers envision far more.

Future versions could handle complex operations like pick-and-place, painting, or multi-step assembly, where tasks must be completed in a particular order. They also hope to extend it to heterogeneous teams, where different kinds of robots—some strong, some precise, some mobile—work together like a mixed cast of dancers, each with a unique role.

This vision points toward a future where factories are not rigid, pre-programmed systems, but dynamic environments that adapt instantly to new demands.

The Challenges Ahead

Of course, the technology is not without limitations. RoboBallet does not yet handle task dependencies, where one robot’s action must follow another’s in sequence. It also does not account for robots with different capabilities or for the full complexity of every possible industrial layout.

But the researchers are optimistic. They argue that the flexible design of RoboBallet’s graph-based architecture makes it well-suited for future enhancements. Each version will bring the system closer to a universal solution for robot coordination.

A Dance Between Humans and Machines

The broader story of RoboBallet is not just about efficiency—it’s about the relationship between humans and machines. For centuries, factories have been places of rigid, repetitive labor. With automation, they became places where humans managed machines. Now, with AI choreographing robot movements, factories may become places of creativity, flexibility, and harmony.

This does not mean humans will be replaced. Instead, it suggests a new partnership. Just as a choreographer guides dancers while the dancers bring the performance to life, humans will guide factories’ goals while robots carry out the intricate dance of production.

The Beginning of a New Era

RoboBallet is more than an algorithm. It is a glimpse into the future of industry—one where efficiency and elegance are not in conflict but entwined. It shows that even in the cold, mechanical world of robots and steel, there is room for beauty.

Factories of the future may hum not with the sound of grinding gears but with the rhythm of a silent ballet—dozens of robotic arms moving together with superhuman precision, adapting in real time, and turning production into an art form.

In that future, we may look back at the painstaking manual planning of today and wonder how we ever managed without RoboBallet’s graceful intelligence.

More information: Matthew Lai et al, RoboBallet: Planning for multirobot reaching with graph neural networks and reinforcement learning, Science Robotics (2025). DOI: 10.1126/scirobotics.ads1204