In a world increasingly hungry for power and wary of its environmental cost, a remarkable development is taking place—not in a flashy tech lab in Silicon Valley, but beneath the floors of a research building at Binghamton University in New York. Here, the quiet collaboration between two engineering professors has brought life to a technology so elegant, so biologically harmonious, that it seems almost too simple to be true.

Dr. Seokheun “Sean” Choi, a professor of electrical and computer engineering, has spent more than a decade refining biobatteries—living power sources fueled by bacteria. His work has always danced along the border of biology and technology, where nature’s tiniest workers become miniature energy producers. But recently, an unexpected encounter with a colleague just downstairs changed everything.

Dr. Dehao Liu, a mechanical engineering expert in laser powder bed fusion (LPBF)—a next-generation 3D printing technique—was the missing piece in Choi’s vision. Together, they’ve created something that’s more than a battery. It’s a sustainable, reusable power source with a structure literally grown out of steel and science, capable of powering small electronic devices with nothing more than microscopic life.

Microbial Power: Engineering with Life

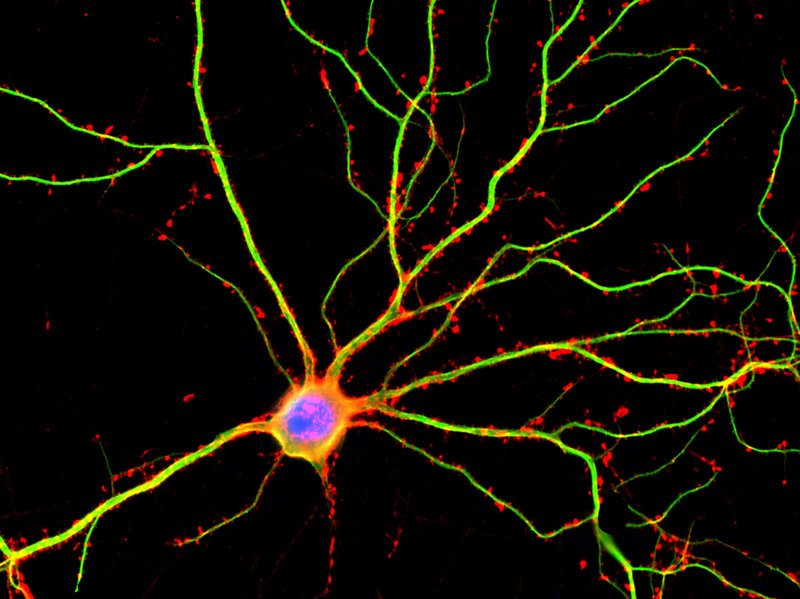

Biobatteries aren’t science fiction. They’re real, tangible devices that rely on bacteria—specifically, endospores—to produce electricity through metabolic processes. These endospores, the dormant and highly resilient forms of bacteria, remain inert until activated by environmental conditions. Once awake, they go to work.

Each biobattery consists of three essential parts: a positive electrode (cathode), a negative electrode (anode), and a membrane that allows ions to pass between them, generating a current. But there’s a catch: for bacteria to thrive and generate power effectively, they need an environment that supports both their metabolism and their movement.

That’s where traditional battery design falls short. Most anodes, the area where bacteria live and release electrons, are flat. In this two-dimensional world, bacteria can’t multiply or function efficiently. Waste accumulates. Nutrients are blocked. The whole system stagnates.

“A two-dimensional anode is not efficient,” Choi explained. “Nutrients will not be delivered effectively to the bacteria, and their waste cannot go out effectively.”

The solution? Build up—literally. Design an anode in three dimensions, allowing bacteria to colonize an environment more like a microscopic jungle gym, full of tunnels and textures that help them thrive. This approach, however, presents its own problem: most 3D printable materials that can survive bacterial environments—like carbon-based or polymer-based composites—lack the electrical conductivity or mechanical strength required. Worse, some fabrication techniques generate heat that would instantly kill the very bacteria needed to run the device.

So, for a long time, Choi was stuck with off-the-shelf stainless steel mesh, which, while conductive and durable, offered little control over structure. That’s when fate—or perhaps just proximity—intervened.

Precision Printing for a Living Machine

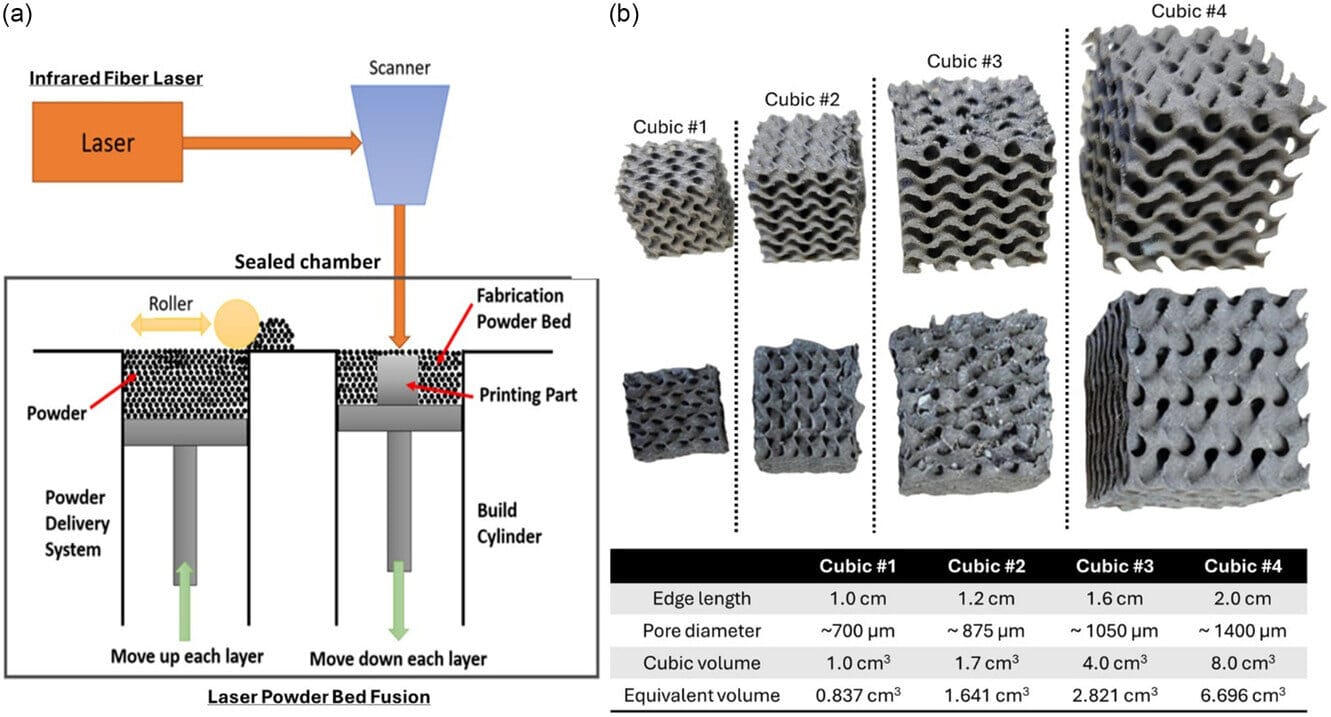

Professor Liu’s mastery of LPBF technology offered the perfect opportunity. LPBF is a metal 3D printing technique where layers of stainless-steel powder are melted by a laser and built up into intricate, fully custom microstructures. These aren’t rough shapes—they’re engineered at the micron scale, allowing for precise control over porosity, texture, and layout.

“LPBF is ideal for biobatteries because it enables high-precision, customizable 3D structures with complex geometries, essential for maximizing surface area and energy density,” Liu said.

Choi and Liu combined forces and designed a brand-new kind of anode using LPBF, tailored precisely for microbial life. For the first time, they could control every ridge, pore, and channel within the electrode—maximizing how bacteria live, breathe, and produce power.

“We saw the potential here,” Choi said. “Then we prepared other components using 3D printing as well, like a sealing cover and the cathode part, and we simply assembled them like Lego bricks.”

The result? A modular, powerful, stackable biobattery that doesn’t just work—it excels.

A Battery Built Like Nature

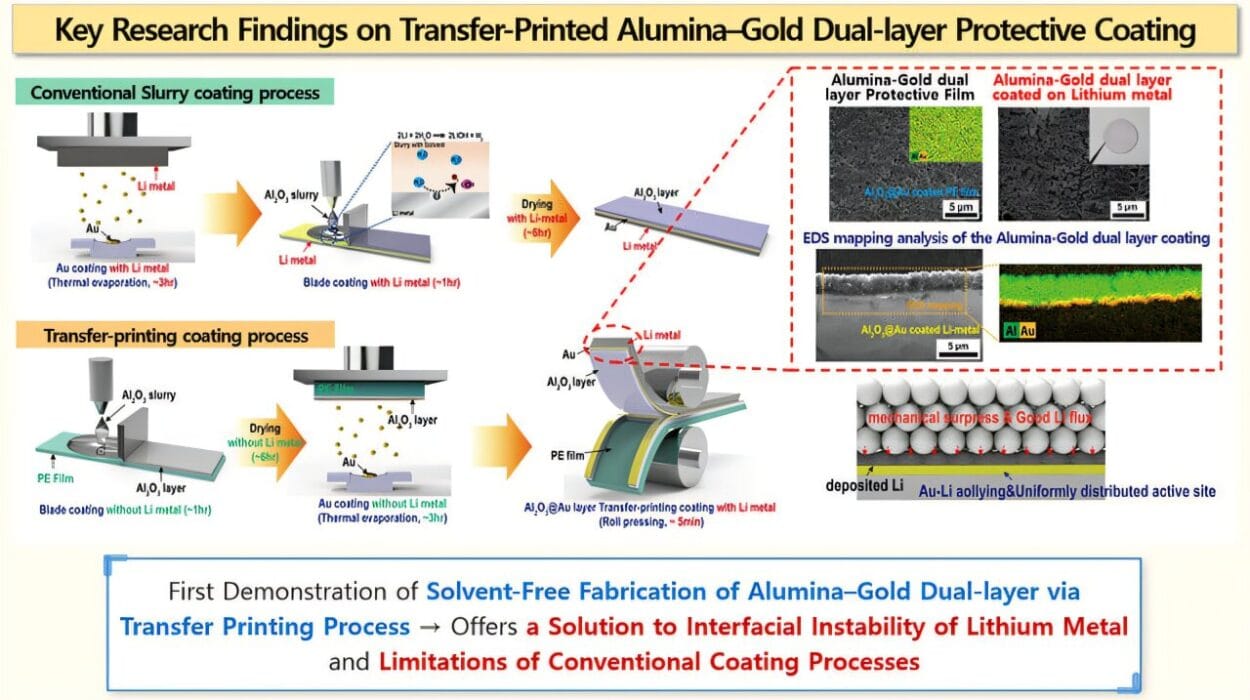

Once constructed, the biobatteries can be linked together in series or parallel, much like traditional batteries. Six connected units recently generated nearly 1 milliwatt of power—enough to light up a 3.2-inch thin-film LCD screen. This output ranks among the highest electrical yields in the field of microbial fuel cells, and it was achieved without toxic chemicals or expensive rare metals.

What makes this design truly special, however, is its sustainability. The bacterial cells used in the system can be detached, cleaned, and reused multiple times without significant power loss. This recyclability is rare in any form of energy technology and could be revolutionary for powering remote sensors or Internet of Things (IoT) devices that are difficult to reach or replace.

Even more impressive is the vision ahead. The team wants to further integrate all components through a unified 3D printing method, eventually producing biobatteries in a single, seamless process. They also aim to develop advanced power management systems, similar to those found in solar panels, to regulate charging and discharging more effectively.

Science, Mentorship, and a Shared Vision

This innovation isn’t just a technical achievement—it’s a story of mentorship and scientific continuity. Assistant Professor Anwar Elhadad, once Choi’s doctoral student, played a key role in the project.

“My Ph.D. focused on developing bioelectronic systems that integrate sustainable energy-harvesting technologies, particularly microbial fuel cells,” Elhadad said. “This research builds on that foundation by addressing some of the key challenges I encountered during my dissertation.”

The culture in Choi’s lab is one of exploration and inclusion. There’s room for failure, for iteration, and for big, audacious ideas. “He encourages creativity and pushes the boundaries of what’s possible,” Elhadad said. “Our collaboration is very hands-on. He has a clear vision but is always open to new ideas.”

For Choi, this project has personal resonance. “I’m so happy about this collaboration,” he said. “It makes this iteration of the biobattery very meaningful to me.”

Beyond the Lab: Imagining a New Energy Future

While the Binghamton team’s invention may seem small—literally—it has global implications. Imagine forest sensors that never need a battery swap. Ocean buoys that draw power from bacteria in seawater. Biodegradable batteries in medical implants. A wireless network of devices, powered not by lithium, but by life itself.

This is energy stripped back to its essence: simple, clean, and alive. It’s the embodiment of nature and engineering working in harmony—not as adversaries, but as co-creators.

And perhaps that’s what makes this story so compelling. It reminds us that innovation doesn’t always roar in with lightning and noise. Sometimes, it bubbles up quietly, in bacteria beneath our feet, nurtured by minds curious enough to look down and ask, “What if?”

Reference: Anwar Elhadad et al, Toward Sustainable, High‐Performance, and Scalable On‐Chip Biopower: Microbial Biobatteries with 3D‐Printed Stainless Steel Anodes and Spore‐Based Biocatalysts, Advanced Energy and Sustainability Research (2025). DOI: 10.1002/aesr.202500199