In a quiet laboratory in Daejeon, South Korea, a breakthrough is unfolding—one that could change the future of batteries as we know them. Behind this transformative discovery is Dr. Jungdon Suk and his team at the Korea Research Institute of Chemical Technology (KRICT). Their innovation may finally resolve one of the most daunting challenges in battery science: the infamous “dendrite problem” that has long haunted lithium-metal batteries.

Published in the respected journal Energy Storage Materials, their work unveils a new transfer printing technology that gently laminates protective hybrid layers onto lithium metal—without using solvents, without causing damage, and with the kind of uniformity required for real-world manufacturing. The implications ripple far beyond the lab, offering a credible path to safer, longer-lasting, high-energy batteries that could reshape electric vehicles, portable electronics, and renewable energy storage.

Why Lithium Metal Is the Future—and the Risk

At the heart of this discovery lies a paradox: lithium metal is both a dream and a danger. As an anode material, it has 10 times the theoretical capacity of the graphite used in today’s lithium-ion batteries. It promises smaller, lighter, more powerful batteries—exactly what’s needed for the next wave of electric vehicles, drones, smartphones, and grid storage systems.

But lithium metal carries a dark side. During repeated charging and discharging, needle-like structures called dendrites can grow on its surface. These dendrites pierce through the battery’s electrolyte, causing short circuits, fires, or even explosions. Despite its enormous potential, lithium metal’s volatility has kept it confined to the fringes of commercial use.

Attempts to control dendrites have been met with limited success. Traditional wet-coating methods—where protective layers are applied using liquid solvents—tend to damage the fragile lithium surface and introduce unwanted contaminants. Scaling these methods up has proven both costly and impractical. That’s where Dr. Suk’s team comes in.

A Gentle Touch: Reinventing Protection with Transfer Printing

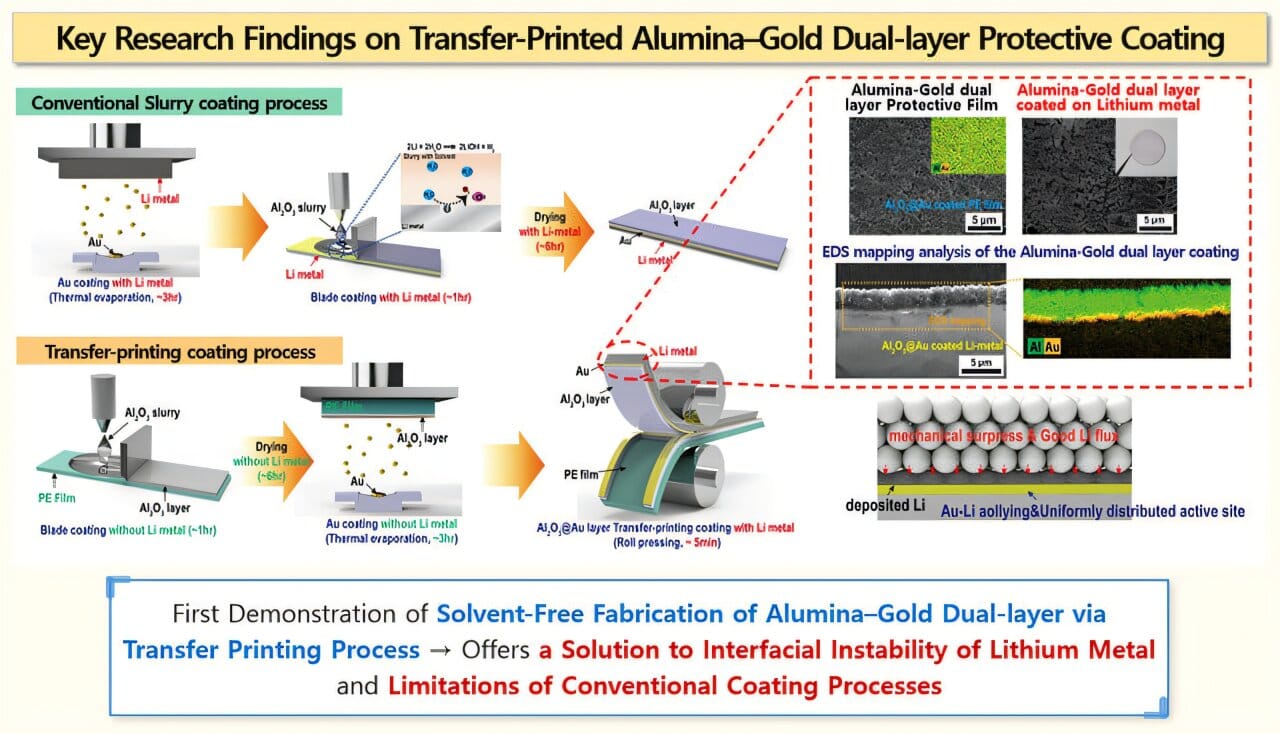

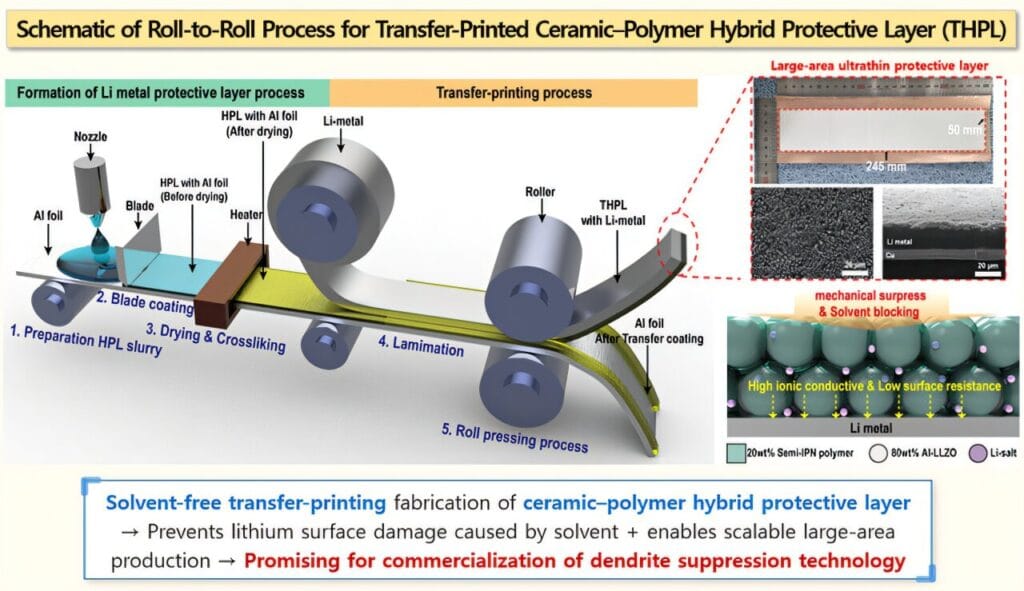

Rather than coating lithium metal directly, Dr. Suk’s team employed a surprising tactic borrowed from printing technology. Their solution? Fabricate ultra-thin protective films on a separate substrate, and then press—transfer—them onto the lithium surface using a roll-based lamination process.

The brilliance of this method lies in its simplicity and precision. By decoupling the layer formation from the application step, the researchers avoid exposing reactive lithium to harmful solvents or mechanical stress. The result is a cleaner, more uniform interface—and a giant leap forward in battery manufacturing.

Dr. Suk explains, “This study combines novel protective materials and a scalable transfer printing process to overcome the critical challenges of interfacial instability and wet-processing limitations in lithium-metal batteries.”

Two Paths to Protection: Ceramics, Polymers, and a Golden Shield

The team explored two key types of protective films. One was a dual-layer of alumina (Al₂O₃) and gold (Au), engineered to block dendrites with robust mechanical resistance and improved ion transport. The other was a hybrid layer made from a combination of ceramic (Al-LLZO) and flexible polymer materials, designed to offer ionic conductivity, structural flexibility, and surface adhesion.

These films, only five microns thick, were laminated over large 245 × 50 mm areas without a single solvent involved. It marked the first successful application of transfer printing in lithium-metal battery protection—and it worked spectacularly.

In earlier tests, the alumina-gold layer kept dendrites at bay while ensuring low interfacial resistance and prolonged battery life. Building on that, the new hybrid protective layers proved capable of guiding lithium ions uniformly across the electrode surface, suppressing uneven growth and extending cycling stability.

Performance That Speaks: The Numbers Tell the Story

Laboratory testing turned theory into reality. In pouch-cell tests—the kind that mimic real battery packaging—the lithium anodes protected by the hybrid layer retained 81.5% of their capacity after 100 charging cycles. Bare lithium cells, by contrast, faded far faster.

Equally impressive was the Coulombic efficiency—a key measure of how well a battery can retain and reuse its charge—which remained at a remarkably high 99.1%. Even when subjected to punishing high-rate conditions that completely discharged the battery in under 10 minutes, the cells kept 74.1% of their original capacity. These numbers are more than benchmarks—they’re indicators that lithium-metal batteries are edging closer to commercial viability.

“This represents one of the most practical solutions for enabling high-energy-density lithium-metal batteries,” said Dr. Young-Kuk Lee, President of KRICT. “It could boost Korea’s competitiveness in the global battery industry.”

Scaling the Summit: A Path to Commercialization

Innovation is only as good as its ability to scale. Many lab-scale breakthroughs stumble when confronted with the demands of industrial production: uniformity, consistency, cost-efficiency. But the beauty of this transfer printing method is that it’s inherently scalable. By using a roll-based lamination process—similar to those already used in electronics and flexible displays—the team has shown that their technology is ready to leave the lab.

What was once a scientific curiosity has now become a manufacturable process. That’s a rare and powerful convergence in materials science.

The hybrid layer’s adaptability also opens the door to other advanced battery systems, including solid-state and lithium-sulfur batteries—two architectures known for their energy density and safety, yet still plagued by interfacial instability. Dr. Suk’s work could become a foundational technology across these platforms, advancing the entire field of next-generation energy storage.

A Spark for the Electric Future

In a world desperate for better batteries—cleaner, safer, and more powerful—the work of Dr. Suk and his team is more than an academic achievement. It is a message of hope wrapped in a sheet of ceramic and polymer, gently pressed onto a sliver of lithium metal.

It is the kind of quiet, meticulous science that rarely makes headlines but shapes the world nonetheless. With climate change, electric mobility, and sustainable energy demanding smarter solutions, this innovation offers not just incremental progress but a paradigm shift.

Transfer printing on lithium metal may not sound like a revolution—but sometimes revolutions begin with a gentle touch.

Reference: Junyoung Choi et al, A scalable transfer-printed hybrid interface for dendrite-free and high-energy lithium-metal batteries, Energy Storage Materials (2025). DOI: 10.1016/j.ensm.2025.104428