Hydrogen has long been hailed as the fuel of the future — a clean, versatile energy source capable of powering everything from heavy-duty trucks to backup power grids. It is the universe’s most abundant molecule and a vital component of industrial chemistry. Yet, for all its promise, hydrogen has been held back by a stubborn reality: it is expensive to purify, challenging to store, and tricky to transport.

That could soon change.

Researchers at Fudan University and partner institutes in China have unveiled a groundbreaking method that could unlock hydrogen’s potential on a massive scale. Their innovation, recently detailed in Nature Energy, offers a simple, low-cost way to separate hydrogen from dirty industrial gas streams, store it safely, and move it to where it’s needed — all while using infrastructure we already have.

It’s not just an advance in chemistry. It’s a potential turning point for the clean energy transition.

The Problem with Dirty Hydrogen

While “green hydrogen” — produced using renewable electricity and water — has captured headlines, the reality is that most of the world’s hydrogen today comes from industrial processes that also generate a cocktail of unwanted gases. In China’s vast manufacturing sector, for example, enormous amounts of crude hydrogen are created as byproducts, often containing over 50% impurities such as carbon monoxide (CO), carbon dioxide (CO₂), nitrogen, and hydrocarbons.

Because purifying such hydrogen using traditional methods — like pressure swing adsorption or high-tech membranes — is expensive and energy-hungry, much of it is simply burned as waste. This represents a colossal missed opportunity.

“We saw a huge gap,” said Prof. Yifeng Zhu, the senior author of the study. “Industry is throwing away vast amounts of hydrogen-rich gas, while the world is struggling to scale up clean hydrogen production. Our work bridges that gap.”

Chemistry Meets Ingenuity

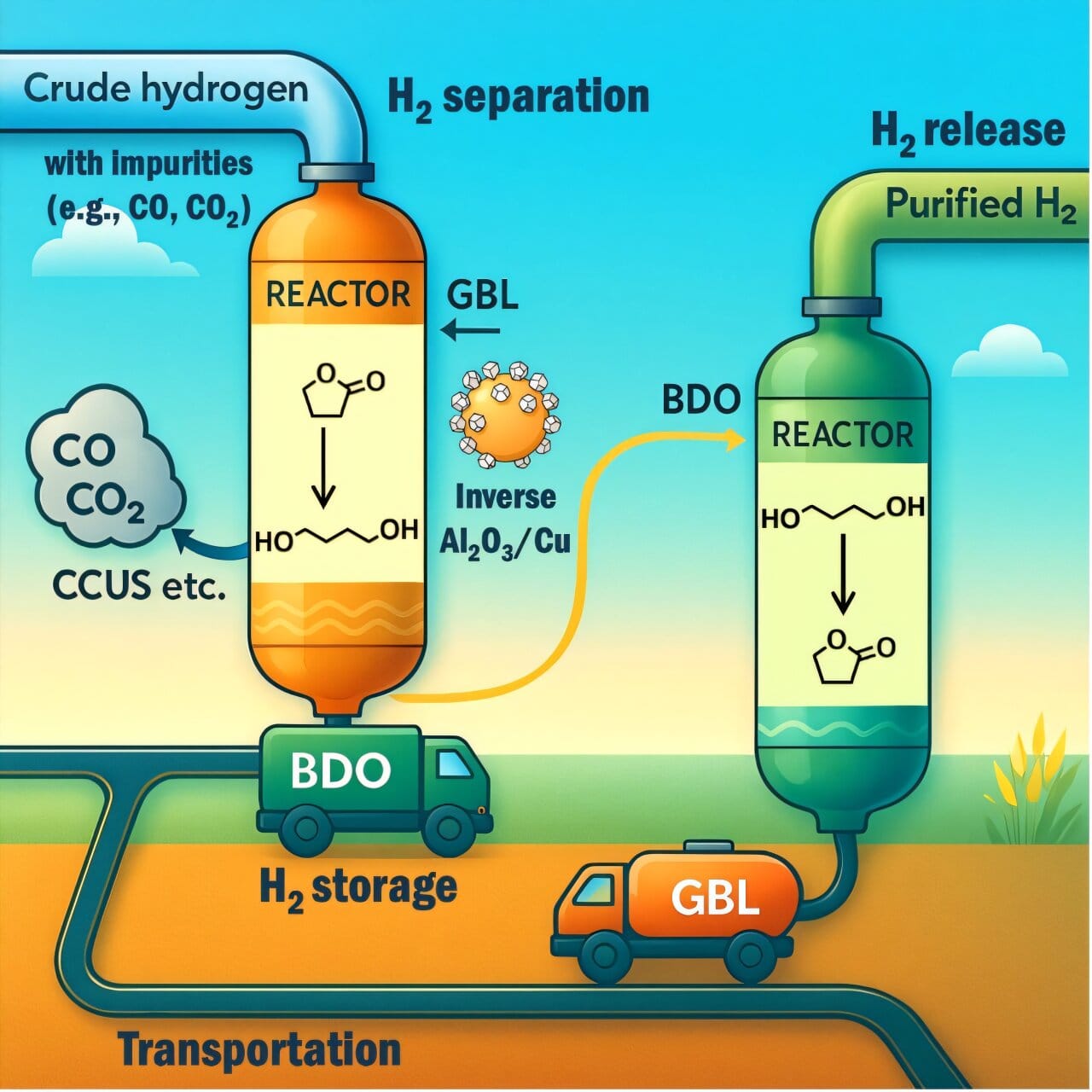

The team’s breakthrough hinges on a clever chemical trick: using two inexpensive organic compounds, γ-butyrolactone (GBL) and 1,4-butanediol (BDO), as a pair of liquid organic hydrogen carriers (LOHCs).

The process works like this:

- Capture — Impure hydrogen is fed into a reactor containing GBL and a low-cost copper-based catalyst. At a modest temperature of 170 °C, the GBL absorbs the hydrogen, transforming into BDO with over 99.2% efficiency — even when the gas is full of CO and CO₂.

- Store & Transport — The hydrogen-rich BDO is a stable, oil-like liquid. It can be handled at room temperature and pumped through existing fuel pipelines, loaded into tanker trucks, or stored in tanks — just like gasoline or diesel.

- Release — At the destination, the BDO is gently heated and catalytically converted back into GBL, releasing ultra-pure hydrogen (>99.998%), free from any carbon contaminants.

“It’s one step for capture, one step for release,” Prof. Zhu explained. “And it works safely, at low cost, using materials that are abundant and non-toxic.”

Why This Matters

The brilliance of this method isn’t just in the chemistry — it’s in its practicality.

Unlike compressed hydrogen gas, which requires high-pressure tanks, or cryogenic hydrogen, which demands ultra-cold storage, the BDO liquid is easy to handle. It doesn’t need specialized containers, and it poses far fewer safety risks. This means the hydrogen economy could piggyback on the existing global fuel infrastructure, bypassing one of the biggest barriers to scaling up.

Even more impressively, the system can handle hydrogen streams that are far “dirtier” than conventional catalysts can tolerate. Many existing purification systems fail when CO or CO₂ levels exceed just 2%, but the Fudan team’s catalyst can work with more than 50% impurities without degrading.

“This isn’t a lab curiosity,” Prof. Zhu emphasized. “It’s designed for the messy, real-world conditions of industrial gas streams.”

From Waste to Wealth

The implications are enormous. Right now, industries around the world flare or vent millions of tons of hydrogen-rich gas each year — an environmental and economic waste. This new process could turn that waste into high-value, clean hydrogen, ready to power vehicles, factories, or the electrical grid.

“Instead of building an entirely new hydrogen infrastructure from scratch, we can start by upgrading what we already have,” Prof. Zhu said. “That means faster deployment, lower costs, and a quicker path to decarbonization.”

Scaling Up for the Future

The research team is already partnering with industrial players to test the system at larger scales. Key goals include proving the long-term stability of their catalyst, fine-tuning the reaction for different gas sources, and expanding the range of carrier liquids for various applications.

Beyond industrial waste hydrogen, Prof. Zhu’s group envisions their method supporting renewable energy storage. Wind and solar farms could use excess electricity to produce hydrogen, store it in BDO, and transport it to cities or industrial hubs without expensive new pipelines.

“It’s a versatile tool,” Prof. Zhu said. “From recycling waste hydrogen to balancing renewable grids, the possibilities are broad.”

A Step Toward the Hydrogen Revolution

Hydrogen’s promise has always been clear: an energy carrier that emits only water when used, offering a way to decarbonize sectors that electricity alone can’t reach. But the roadblocks — cost, storage, transport — have kept it from realizing that promise at scale.

By making hydrogen purification, storage, and transport cheaper, safer, and easier, the Fudan team’s discovery could help unlock the hydrogen economy much sooner than many expect.

“This is a case where fundamental chemistry meets an urgent real-world need,” Prof. Zhu reflected. “If we can bring this technology to market quickly, we can start turning wasted hydrogen into clean power — and that’s a win for both industry and the planet.”

More information: Yue Chen et al, A catalytic cycle that enables crude hydrogen separation, storage and transportation, Nature Energy (2025). DOI: 10.1038/s41560-025-01806-9