Every time an athlete collides on the field, a soldier braces during combat, or a spacecraft hurtles toward a distant planet, one thing is certain: protection matters. Helmets, pads, and landing gear all rely on one critical component—shock-absorbing materials. For decades, engineers have sought to perfect these materials, making them lighter, stronger, and more efficient. Now, a team of mechanical engineers at the University of Wisconsin–Madison has taken a bold new step forward, reshaping how we think about protective foams.

Their research, led by Associate Professor of Mechanical Engineering Ramathasan Thevamaran, offers a revolutionary design framework that could accelerate the development of shock-absorbing materials used everywhere from sports equipment to aerospace exploration. And perhaps most impressively, this advance challenges long-held assumptions about what makes a material truly protective.

Breaking Away from Conventional Wisdom

Traditionally, engineers designing shock-absorbing foams focused on one guiding principle: keep stress constant. In other words, if the foam could maintain a “plateau” of stress while absorbing energy from an impact, it was considered ideal. This design rule shaped countless products, from football helmet liners to protective packaging.

But Thevamaran and his team wondered—what if that assumption was limiting innovation?

Instead of focusing only on the foam’s mechanical properties, they looked at the bigger picture: how the material’s thickness and area interact with its mechanical behavior during an impact. Their results were surprising.

In some scenarios, foams that did not hold stress constant—those with what’s called a nonlinear stress-strain response—actually performed better. By bending the rules of tradition, they uncovered an expanded design space, opening doors to lighter, thinner, and more adaptable protective materials.

“This work shows that foams traditionally considered as ‘ideal absorbers’ aren’t always the best,” Thevamaran explains. “We show that foams with a nonlinear response can, in fact, offer better performance, especially when compact pad design is required.”

Building a Framework for the Future

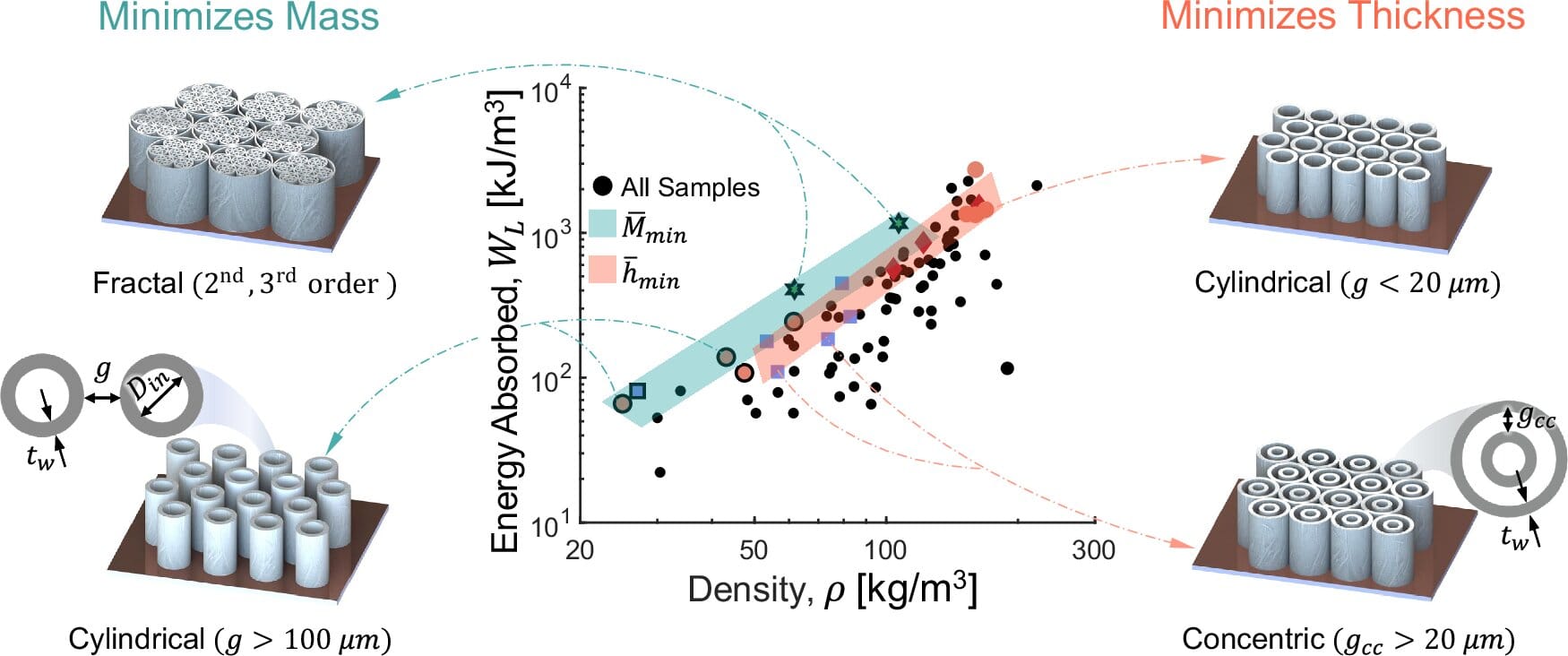

The team didn’t just stop at theory. They built a comprehensive design framework that allows engineers to input variables like foam thickness, surface area, material properties, and impact thresholds. With those inputs, the framework generates a design map—a guide showing how to achieve the best energy absorption for a specific application.

This means designers can skip much of the expensive and time-consuming trial-and-error process. Instead, they can quickly identify the exact foam geometry and material behavior needed for their project, whether that’s a lighter helmet for athletes or a compact landing pad for spacecraft.

“It allows designers to customize the material for the best performance, tailored to diverse applications, without going through lots of experimental trial and error,” Thevamaran says.

From the Lab to Real-World Impact

To prove the power of their framework, the UW–Madison team tested it with architected vertically aligned carbon nanotube foams—materials they have been developing for years. These futuristic foams, made from networks of microscopic carbon structures, showed optimal protective properties when guided by the new framework.

But the framework is not limited to cutting-edge nanomaterials. It applies broadly, from everyday polymer foams used in helmets to advanced metamaterials engineered for aerospace. This universality makes the advance especially powerful.

“The findings are very general and applicable to a wide range of material systems,” Thevamaran notes. “Notably, they open the door to designing protective materials with greater precision and flexibility.”

Applications That Touch Every Life

The potential uses for this research are vast. Imagine a soldier’s helmet that provides maximum protection while remaining light enough to reduce fatigue. Or consider a football helmet that better guards athletes against concussions without feeling bulky. Beyond Earth, spacecraft could land more safely on alien surfaces with struts designed to absorb maximum energy in minimal space.

Even everyday products—from protective packaging to car safety systems—could benefit from foams tailored with surgical precision to absorb shock where it matters most.

A Freely Shared Innovation

In an inspiring move, the UW–Madison researchers have made their design framework freely available online. This means scientists, engineers, and designers worldwide can immediately begin experimenting with it, accelerating innovation across industries. By sharing their work openly, the team hopes to spark a wave of new designs that protect people and machines in ways never before possible.

A Shift in Perspective

Science often advances not just by solving problems, but by questioning the assumptions that shape them. For decades, engineers assumed constant stress was the hallmark of the best shock absorbers. By daring to ask “what if,” Thevamaran and his team discovered something deeper: sometimes, imperfection in stress response leads to perfection in protection.

Their work, published August 4, 2025, in Nature Communications, is more than just a technical achievement—it’s a reminder that progress comes from curiosity, courage, and the willingness to rethink old truths.

Protecting the Future

Whether cushioning the fall of an athlete, shielding a soldier from harm, or softening the impact of a spacecraft touching down on another world, shock-absorbing materials stand between humans and danger. Thanks to the pioneering work of UW–Madison engineers, the future of protection looks lighter, smarter, and safer.

In reimagining the very fabric of safety, they’ve not only challenged conventional wisdom—they’ve expanded the horizon of possibility.

More information: Abhishek Gupta et al, Embracing nonlinearity and geometry: a dimensional analysis guided design of shock absorbing materials, Nature Communications (2025). DOI: 10.1038/s41467-025-60300-8