Imagine a future where fleets of flying robots hover effortlessly above a construction site, swapping tools in midair with the coordination of a surgical team. Picture drones that can repair wind turbines hundreds of meters above the ground, replace parts on space stations, or assist in disaster zones too dangerous for humans. This vision is no longer confined to science fiction—it is beginning to take flight.

Researchers from Westlake University in China have introduced a groundbreaking development in drone technology known as the FlyingToolbox, a system that allows multiple flying robots to exchange tools midair with remarkable precision. Published in the journal Nature, this achievement represents a major step forward in the evolution of flying manipulator robots—machines capable of interacting physically with the world while airborne.

The Promise of Flying Manipulator Robots

Flying manipulator robots are not your average drones. Unlike typical quadcopters designed for surveillance or photography, these machines are equipped with robotic arms or manipulators that allow them to grasp, move, and interact with objects. Their ability to operate in hard-to-reach or hazardous locations makes them invaluable for industries such as construction, inspection, maintenance, and even search-and-rescue missions.

In environments where human workers face extreme risks—like high-voltage power lines, nuclear facilities, or disaster zones—these flying robots can perform delicate and dangerous tasks with surgical precision. However, their potential has long been limited by one key challenge: cooperation.

To achieve complex, continuous operations, drones must be able to work together seamlessly, sharing tools or passing objects between one another. Until now, this has been incredibly difficult to achieve in practice.

The Challenge of Downwash

The major obstacle to aerial cooperation lies in a phenomenon known as downwash—a strong stream of air generated by a drone’s spinning propellers. When one drone hovers above another, this downward airflow creates turbulence that disrupts stability, making precise maneuvers like docking or passing tools nearly impossible.

Imagine trying to hand someone a delicate object while standing in the middle of a hurricane—that’s what drones face when they attempt to stack or exchange equipment midair. Downwash interference has, until recently, kept the dream of cooperative flying robots grounded.

The Innovation: The FlyingToolbox System

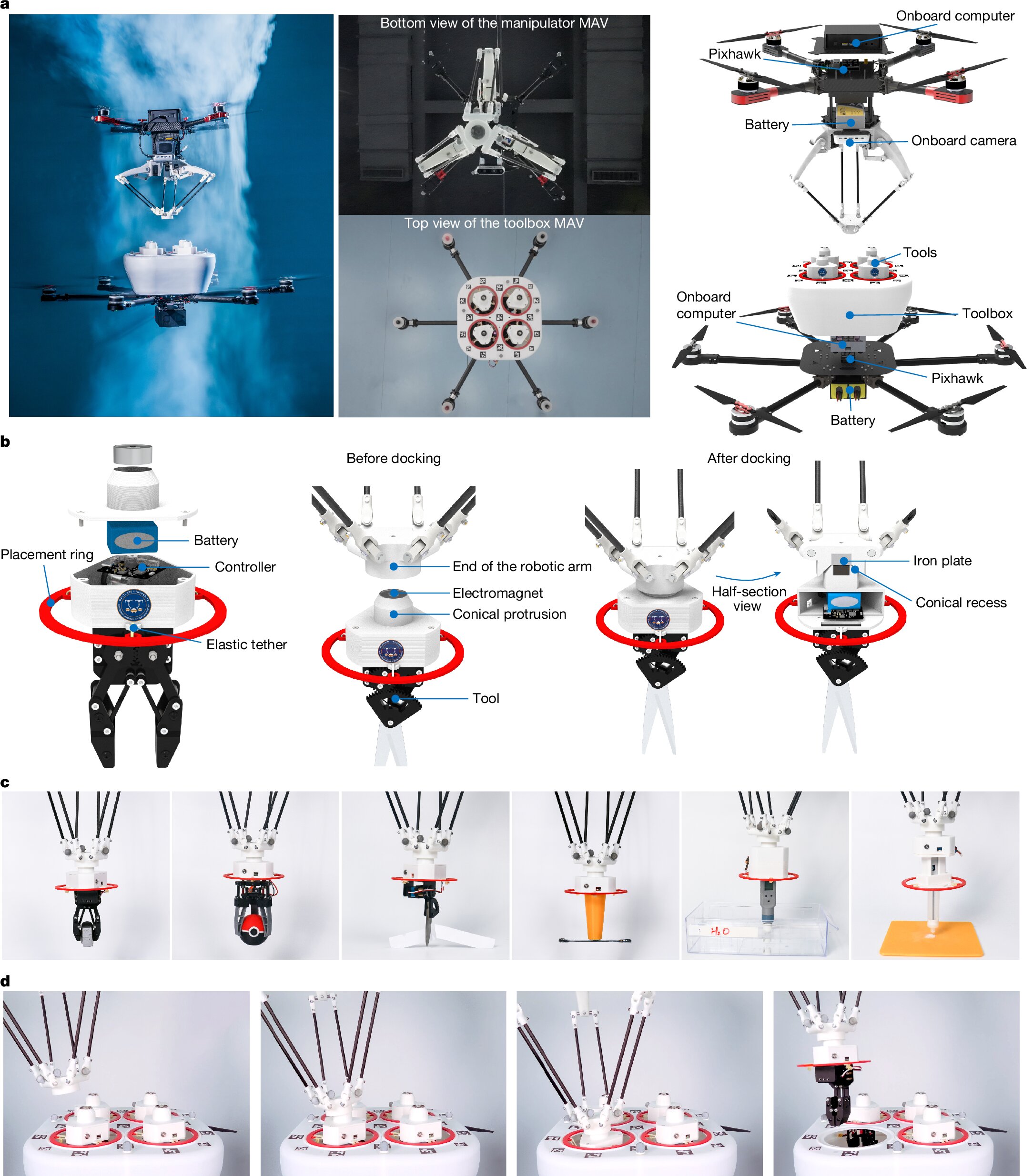

The team at Westlake University tackled this problem with a brilliant blend of mechanical design, artificial intelligence, and real-time control. The FlyingToolbox system consists of two types of micro-aerial vehicles (MAVs):

- The Toolbox MAV, which serves as a flying platform that holds multiple tools.

- The Manipulator MAV, equipped with a robotic arm designed to pick up and swap tools from the toolbox while both are airborne.

At the heart of this innovation lies an onboard vision system that uses QR-code-like markers for precise positioning. The drones can “see” each other and align themselves with sub-centimeter accuracy. Meanwhile, a neural network-based estimator continuously predicts and compensates for downwash disturbances in real time, allowing stable docking despite the turbulence.

To make the actual exchange possible, the researchers designed an electromagnetic docking mechanism combined with elastic tethers that absorb mechanical stress and ensure secure tool attachment. This ingenious system allows the manipulator drone to grab and release tools midair, just as a nurse might hand different instruments to a surgeon during an operation.

Defying Turbulence: How Precision Was Achieved

The researchers didn’t just simulate success—they proved it. During testing, the drones performed a series of complex, multi-stage tasks, switching tools both while hovering and while moving. The team conducted 20 consecutive docking trials, testing accuracy, repeatability, and resilience under turbulent conditions.

The results were extraordinary. Even with a downwash airflow of 13.18 meters per second—strong enough to exert a force of 24.9 newtons, or about 40% of the toolbox drone’s weight—the FlyingToolbox system maintained a docking accuracy of 0.80 ± 0.33 centimeters.

To put that into perspective, previous systems could only manage an accuracy of 6 to 8 centimeters under far less turbulence. The improvement is not merely incremental—it’s exponential. Such precision marks a turning point in aerial robotics, opening the door to new levels of cooperation and autonomy.

How the System Thinks and Reacts

The success of the FlyingToolbox lies in its ability to think and react dynamically. The system’s neural network estimator acts as a kind of artificial intuition, learning how downwash behaves under different conditions. When the manipulator drone approaches the toolbox, the AI predicts how air currents will shift and adjusts the drone’s position and thrust accordingly, maintaining stability and control.

This means the FlyingToolbox doesn’t just follow a pre-programmed flight path—it adapts. Each movement is informed by sensory feedback and real-time learning, allowing it to handle unpredictable airflow with a level of finesse that mirrors biological flight systems like birds or insects.

A Leap Toward True Aerial Collaboration

The implications of this achievement reach far beyond the lab. The ability for drones to exchange tools and work collaboratively while flying could revolutionize multiple industries.

In industrial maintenance, drones could autonomously repair structures like wind turbines or bridges, swapping tools midair without needing to return to base. In disaster response, fleets of flying robots could coordinate to deliver supplies, clear debris, or even perform first aid in locations too dangerous for humans.

In space applications, the concept could one day enable autonomous robots to assemble or repair satellites and space habitats—tasks currently requiring costly and risky human missions.

Testing in the Real World

So far, the FlyingToolbox has only been tested in controlled indoor environments. The next challenge lies in adapting it to outdoor conditions, where unpredictable wind patterns, weather, and environmental noise could affect performance.

The researchers acknowledge these hurdles but remain optimistic. They emphasize that the accuracy, robustness, and versatility of the system make it a strong foundation for future development. As they write, “The accuracy, robustness and versatility of the system make it a potential solution for a wide range of real-world tasks. We believe that it may inspire the community to develop complex cooperative aerial manipulation systems.”

The Broader Impact of Cooperative Robotics

The FlyingToolbox project is part of a larger trend in robotics toward cooperation and adaptability. In nature, success often depends on collaboration—ants build colonies, bees coordinate in hives, and birds migrate in synchronized formations. The same principle is beginning to shape robotic design.

Rather than relying on a single, highly complex machine, engineers are developing systems of smaller, specialized robots that work together intelligently. This shift toward “swarm robotics” mirrors natural systems and offers a more flexible, resilient approach to solving complex problems.

The FlyingToolbox is a perfect example of this philosophy in action—a small, elegant system that demonstrates how coordination and communication can amplify the capabilities of individual machines.

The Human Parallel

There’s a poetic symmetry between how humans collaborate and how these flying robots now operate. In an operating room, a surgeon relies on a nurse’s assistance to maintain focus and efficiency. Similarly, the manipulator drone depends on the FlyingToolbox to provide the right tools at the right moment.

This partnership between machines is more than a technical achievement—it’s a reflection of intelligence in its purest form: the ability to cooperate, adapt, and evolve.

Toward a Sky Full of Possibilities

The FlyingToolbox represents more than an engineering milestone—it’s a glimpse into the future of autonomous collaboration. It suggests a world where drones no longer just observe or deliver, but create, repair, and build.

As technology advances, we may soon see swarms of intelligent flying machines working above cities, maintaining infrastructure, assisting in emergencies, or even exploring alien worlds. These aerial collaborators will extend human reach into places we cannot safely go, acting as our eyes, hands, and partners in the skies.

In the story of technological evolution, the FlyingToolbox marks the moment when flight gained not just mobility, but dexterity and cooperation. It’s a step toward a world where machines do not merely fly—they work together in harmony, mirroring the intelligence and teamwork that define life itself.

More information: Huazi Cao et al, Proximal cooperative aerial manipulation with vertically stacked drones, Nature (2025). DOI: 10.1038/s41586-025-09575-x