Beneath our feet and across the machines that shape our modern lives lies a hidden world: one composed not of solid slabs or flowing liquids, but of grains. Sand, soil, coffee grounds, powders in pills, and particles in fuel beds—all are forms of granular materials, a deceptively simple but scientifically complex class of matter that behaves unlike solids, liquids, or gases. Now, a revolutionary leap in our ability to model and predict how these materials move is opening new frontiers in geotechnical engineering, agriculture, energy systems, and pharmaceutical manufacturing.

At the center of this innovation is the Pore Unit Assembly–Discrete Element Model (PUA-DEM), a state-of-the-art computational framework developed by a research team at the Hong Kong University of Science and Technology (HKUST), led by Professor Zhao Jidong from the Department of Civil and Environmental Engineering. The breakthrough, recently published in the Proceedings of the National Academy of Sciences, offers an unprecedented window into the elusive dynamics that govern the behavior of granular materials under real-world conditions.

What makes this development extraordinary is not just its mathematical elegance, but its practical versatility. From predicting landslides before they occur to transforming the way we make medicine, PUA-DEM is poised to fundamentally reshape our understanding of granular flow—and by extension, our ability to control it.

A Century-Old Problem, Reimagined

Granular materials have always been puzzling. Pour sand into a pile, and it flows like a liquid. Step on it, and it resists like a solid. Shake it, and it might suddenly collapse. Add a bit of water, and the behavior changes again—suddenly, grains stick together, form clumps, or resist motion entirely. These transitions are not just academic curiosities. They underlie critical phenomena like soil erosion, fluid leakage in underground reservoirs, mudslides, and even clogging in manufacturing equipment.

Traditionally, scientists and engineers have tried to model these materials using continuum theories—treating them like smooth, flowing substances—or simple discrete simulations that failed to account for the complicated interactions between particles, fluids, and forces. Especially elusive have been conditions in which the materials are partially saturated—where both air and water co-exist in the spaces between particles.

Enter PUA-DEM, the first model of its kind to deeply integrate the multi-phase interactions between particles, water, and air—not as secondary features, but as primary, dynamic players in the system.

Unveiling PUA-DEM: Physics at the Pore Scale

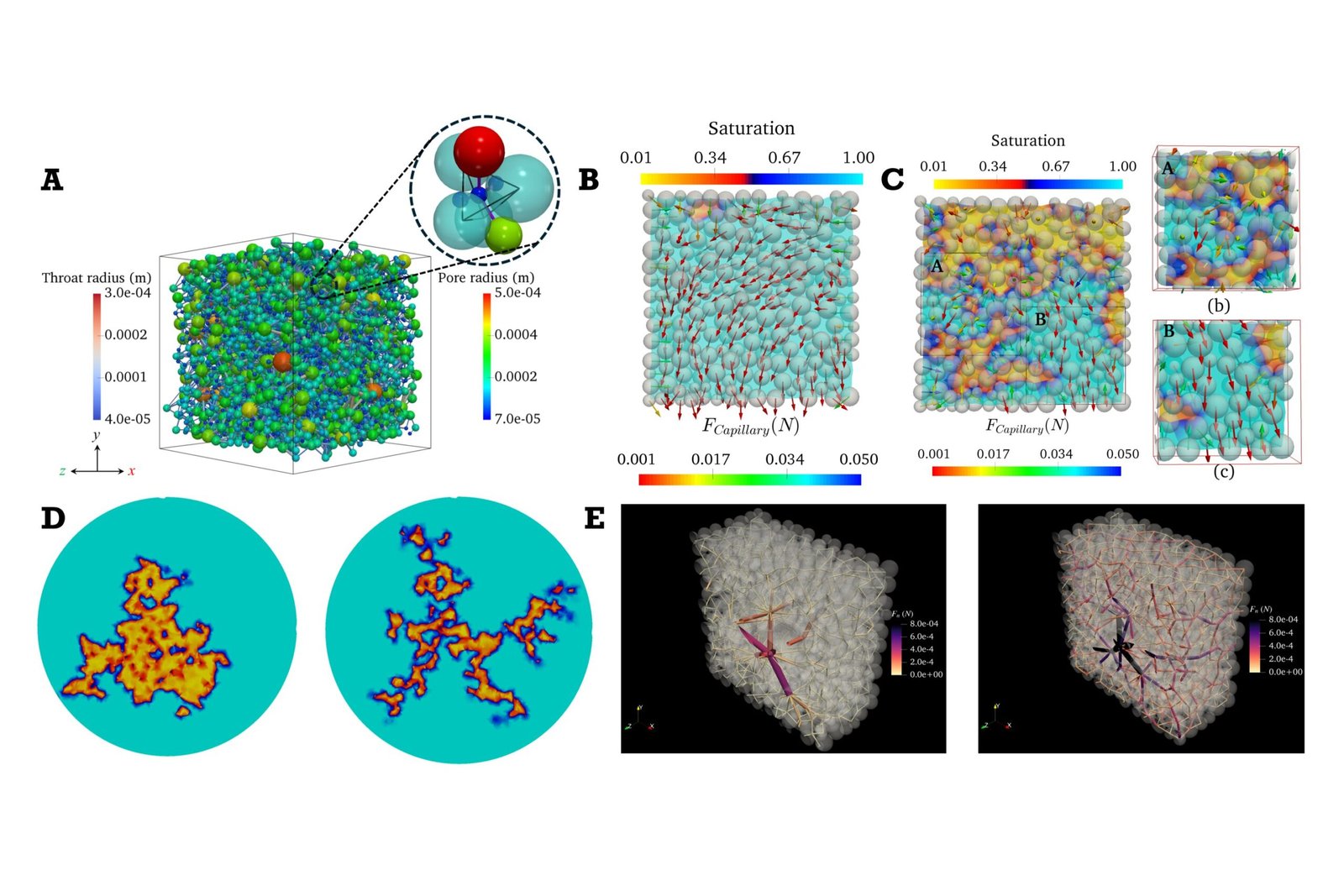

The magic of PUA-DEM lies in its attention to the microscopic, or more precisely, the pore scale. Imagine zooming in on a handful of soil. Between each grain are tiny voids—or pores—sometimes filled with air, sometimes with water, sometimes both. In those spaces, minute physical forces arise: capillary bridges, viscous drag, surface tension, and even cohesive forces due to partial saturation. These micro-interactions dramatically shape the bulk behavior of the material—whether it collapses under stress, holds its shape, or allows fluid to flow through it.

Previous models treated these phenomena as side effects. PUA-DEM builds them into the foundation of the simulation. It does so by representing each grain as a discrete entity and calculating how forces act across the interfaces of each tiny pore. It also models how water and air dynamically move, interact, and redistribute in response to changes in stress or boundary conditions.

This creates a multi-way coupling between particles and fluids, unlike the simpler one-way coupling in older systems that often treated fluids or particles as passive. The result is a fully dynamic simulation that captures both mechanical deformation and fluid flow with high fidelity, across any saturation level—from bone-dry to waterlogged.

From Mudslides to Medicine: Real-World Impacts

The real power of PUA-DEM comes from its adaptability to real-world challenges.

Take landslides, for example. In mountainous regions and construction zones, sudden slope failures pose catastrophic risks to life and infrastructure. These events often occur after rainfall saturates the soil, changing its internal stress state. PUA-DEM allows researchers to simulate how water infiltrates soil pores, how the pore water pressure evolves, and how that pressure leads to microscopic rearrangements that culminate in large-scale collapse.

By modeling such events from the grain up, the system offers a foundation for early-warning technologies that could save lives and reduce economic loss.

In agriculture, water usage is a critical challenge. Modern irrigation systems must balance efficiency, root hydration, and soil health. By modeling how water travels through unsaturated soils and interacts with root systems at the micro-level, PUA-DEM can optimize irrigation strategies, reducing water waste and improving crop resilience under changing climate conditions.

Energy applications are equally compelling. In carbon sequestration and oil extraction, understanding how fluids move through porous underground media is vital. Inaccurate modeling can lead to dangerous leakage of greenhouse gases or inefficient extraction of valuable resources. PUA-DEM’s high-resolution insights make it possible to simulate these systems with unprecedented accuracy, guiding safer and more sustainable energy practices.

The Powder Puzzle: A New Era for Pharmaceuticals

One of the most exciting and unexpected applications of PUA-DEM lies in pharmaceutical manufacturing. Modern drugs often come in powder form—whether as capsules, tablets, or inhalable therapies. Producing consistent, safe, and effective medications depends heavily on controlling how powders flow, compress, and dissolve.

Yet powder processing is notoriously unreliable. Tiny changes in humidity or ingredient size can cause machines to clog, tablets to fracture, or dosages to become uneven. Until now, manufacturers have relied on trial-and-error methods, combined with coarse simulations that don’t capture the fluid-particle interactions that occur in real-time.

PUA-DEM flips the script. By modeling the capillary bridges that form between powder grains, and how these bridges evolve under stress or moisture changes, it offers the ability to simulate every stage of production—from powder mixing to tablet formation. The implications are enormous: safer drugs, fewer recalls, more efficient production, and higher therapeutic reliability for patients.

As Prof. Zhao explains, “This model allows us to predict how microscopic processes—like the formation of a capillary bridge between two particles—can scale up to influence the quality of a tablet or the efficiency of a fluidized bed reactor. That kind of control was simply impossible before.”

Food, Fertilizer, and Formula: Granular Science for Everyday Life

Beyond pharmaceuticals, the food industry stands to gain from PUA-DEM’s capabilities. Foods like sugar, instant coffee, infant formula, and flour are all granular systems that must dissolve quickly, maintain shelf stability, and resist caking.

PUA-DEM enables simulations of how texture, moisture content, and particle geometry influence these properties. Manufacturers can now design granular food products with optimized mouthfeel, faster dissolution rates, and longer shelf life, all while reducing energy consumption and minimizing waste.

In fertilizers, which are also granular and hygroscopic (tending to absorb moisture), the model helps predict moisture uptake, clumping, and nutrient release rates, enabling more efficient and sustainable farming practices.

The Future of Granular Flow Modeling

While the current PUA-DEM model is groundbreaking, the research team at HKUST is not resting on its laurels. According to Dr. Amiya Prakash DAS, the study’s first author and recent Ph.D. graduate from HKUST, the next steps involve incorporating irregular particle shapes and wettability effects—two features that bring the model even closer to the messy complexity of real-world materials.

“We also plan to develop hybrid computational strategies,” says Dr. Das, “to model reactive transport and drying-induced cracking—phenomena that are crucial in environmental cleanup, construction, and advanced manufacturing.”

This speaks to a broader trend in science and engineering: the fusion of high-fidelity modeling with real-world application, enabling a new era of predictive design in systems once considered too complex to simulate accurately.

Engineering the Invisible

Granular materials are all around us, and yet their mechanics have long defied precision. PUA-DEM, by bridging the microscopic and the macroscopic, marks a turning point—not just in computational modeling, but in our ability to engineer systems that are safer, more efficient, and more responsive to the chaotic forces of the natural and industrial world.

From the dusty trail of a landslide to the chalky consistency of a tablet, from the loamy breath of irrigated farmland to the finely tuned texture of baby formula, the invisible forces that bind and break grains are becoming legible, predictable, and—finally—controllable.

In a world facing increasing challenges from climate volatility, population growth, and industrial complexity, models like PUA-DEM are more than just technical achievements. They are tools of resilience, blueprints for innovation, and proof that even the smallest grains can move mountains—especially when we know how to read their flow.