Imagine a car bumper that pops back into shape after a collision, or an airplane wing that can repair tiny cracks mid-flight. This is not the stuff of science fiction—it’s the promise of a remarkable material called Aromatic Thermosetting Copolyester, or ATSP.

Aerospace engineering and materials science researchers at Texas A&M University, in collaboration with The University of Tulsa, have uncovered new and surprising abilities in this ultra-durable, recyclable “smart plastic.” Their findings, published in Macromolecules and the Journal of Composite Materials, could reshape industries where performance and safety are paramount.

Led by Dr. Mohammad Naraghi, director of the Nanostructured Materials Lab and professor of aerospace engineering at Texas A&M, the team explored ATSP’s unusual ability to recover its shape and heal structural damage on demand—all while maintaining exceptional strength and recyclability.

When Failure Isn’t an Option

“In aerospace applications, materials face extreme stress and high temperatures,” Naraghi explained. “If any of these elements damage a component and disrupt its performance, you could perform on-demand self-healing.”

That means damage in critical systems—like the carbon-fiber composite panels used in modern aircraft—might one day be repaired without replacing the part. Instead, a simple controlled heating process could restore the structure.

But the potential doesn’t stop at airplanes. The automotive industry could also benefit from ATSP’s resilience. “Because of the bond exchanges that take place in the material, you can restore a car’s deformations after a collision,” Naraghi said. “Most importantly, you could significantly improve vehicle safety by protecting passengers.”

Strength, Sustainability, and Smarts

ATSP belongs to a category of advanced materials called vitrimers, which combine the best of both thermoplastics and thermosets. Thermoplastics can be reshaped and recycled, while thermosets offer superior stability and resistance to heat. ATSP, reinforced with carbon fibers, merges these strengths into something extraordinary: several times stronger than steel, yet lighter than aluminum.

And unlike most plastics, ATSP is fully recyclable. “These vitrimers, when reinforced with discontinuous fibers, can undergo multiple recycling cycles,” Naraghi said. “You can crush it, mold it into a new shape, and the chemistry doesn’t degrade.”

This makes ATSP a rare combination of eco-conscious design and high-performance engineering—qualities that are increasingly important in industries under pressure to reduce waste without compromising quality.

Built-In Intelligence

The magic of ATSP lies in its molecular architecture. Its “smart” properties come from a network of bonds that can rearrange themselves when heated.

“Shape recovery and self-healing are two facets of the same mechanism,” Naraghi explained. “Shape recovery happens when bonds reorganize within a continuous piece of material, almost like a built-in intelligence. Self-healing happens when those same bond exchanges repair cracks or breaks.”

To explore these properties, the researchers used a cyclical creep testing method—stretching the material repeatedly while monitoring how it stored and released strain energy. They identified two critical temperatures:

- Glass transition temperature: where the polymer chains become more mobile.

- Vitrification temperature: where bonds exchange rapidly enough to heal and reshape the material.

By heating the composite to around 160°C, they could trigger rapid shape recovery and healing, even after repeated stress cycles.

A Material That Gets Stronger

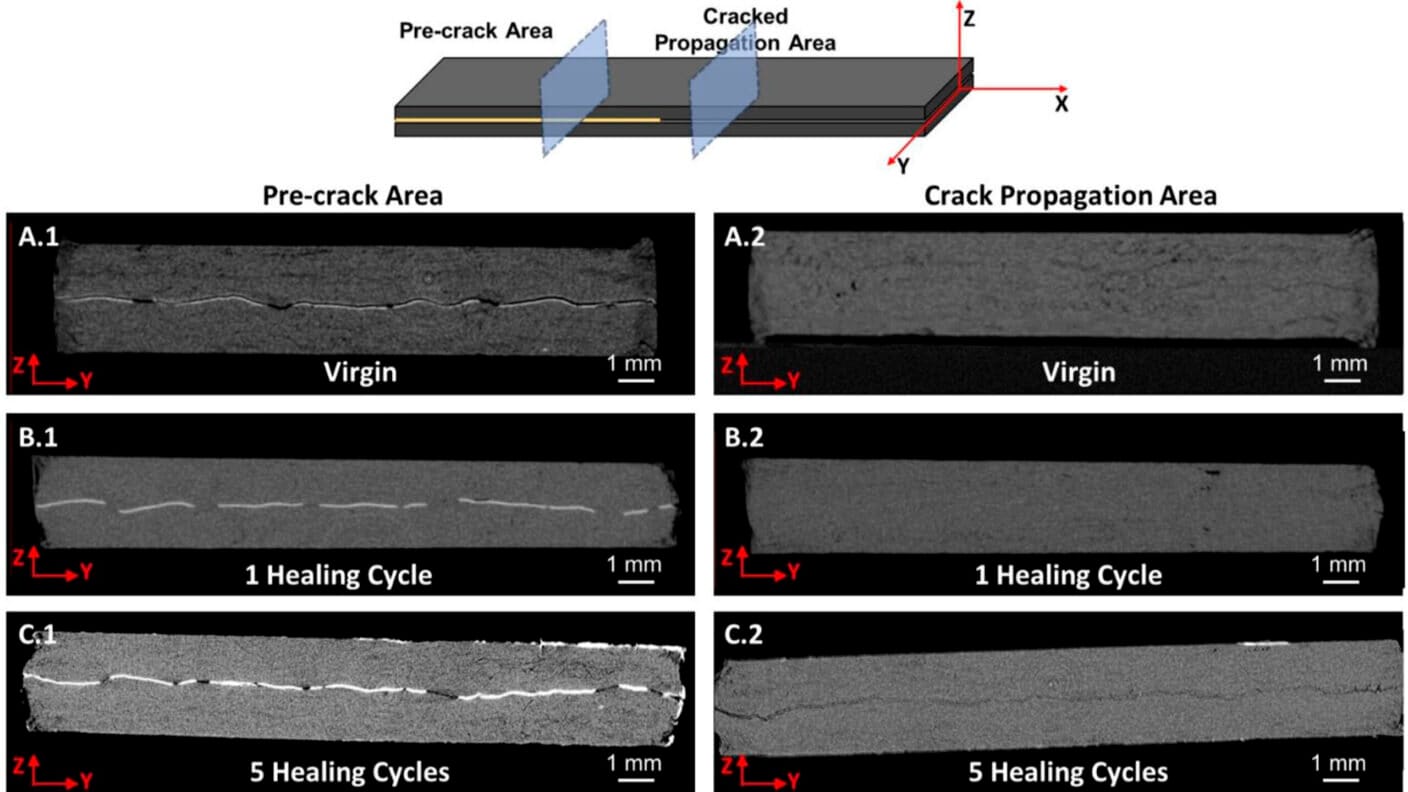

In one test, the team bent ATSP composites to simulate mechanical fatigue, then heated them to activate self-healing. Astonishingly, the material didn’t just repair itself—it became more durable after each healing cycle.

“It’s a lot like skin,” Naraghi said. “Skin can stretch, heal, and return to its original shape. ATSP deforms, heals, and ‘remembers’ its original form—sometimes ending up stronger than before.”

When the researchers pushed the material to its limits—five rounds of stress and healing at 280°C—ATSP still retained about 80% of its strength by the fifth cycle. The drop was due to mechanical wear, not chemical breakdown.

“We saw no thermal degradation or breakdown in the material,” Naraghi emphasized. “That’s a critical point—it’s not just healing, it’s surviving extreme conditions.”

The Road Ahead

While ATSP is still in the research phase, its implications are enormous. Aerospace and defense sectors could benefit from lighter, stronger, more reliable components. Automakers could design cars that are safer and more sustainable. Even consumer electronics could incorporate self-healing materials for longer-lasting products.

For Naraghi, the journey from lab experiment to industry application is built on collaboration. “My students and post-docs do the heavy lifting,” he said. “It’s through trial, error, and partnerships that we turn exciting curiosity into impactful applications.”

The message is clear: the future of plastics is not just about lasting longer—it’s about adapting, evolving, and repairing themselves. ATSP may be just the beginning of a new era where materials behave more like living systems, responding to damage with resilience instead of failure.

And if the vision of a plane wing that heals itself mid-flight sounds bold, remember—so did the idea of flight itself, once upon a time.

More information: Louis O. Vaught et al, Shape Memory and Fatigue Reversal in a Covalent Adaptive Network Polymer below Glass Transition Temperature, Macromolecules (2025). DOI: 10.1021/acs.macromol.4c02376

Tanaya Mandal et al, Identifying the origin of intrinsic self-healing gradual decay in vitrimer carbon fiber reinforced polymer composites, Journal of Composite Materials (2025). DOI: 10.1177/00219983251362394