Electric motors are at the very heart of modern civilization. They whir inside your washing machine, glide your electric car forward, and keep your refrigerator humming. Whether you’re spinning the disk of a hard drive or lifting a heavy elevator, you’re relying on the quiet, powerful forces of an electric motor. But behind this apparent magic lies one of the most profound and beautiful principles of nature: electromagnetism.

To the untrained eye, an electric motor might seem like just a box that makes things move. But peel back its metal casing, and you’re entering a world where invisible fields twist and turn, where electricity gives birth to magnetism and magnetism guides motion. Understanding how an electric motor works is not just about gears and coils—it’s about understanding one of the most unified and elegant phenomena in physics.

From Static to Kinetic: The Dawn of Electromagnetic Thought

To appreciate how electric motors work, we must journey back in time to when electricity and magnetism were seen as separate curiosities. In the 18th century, electricity could shock you, and magnets could nudge a compass needle—but no one thought they were connected. That all changed in the early 19th century, when Danish physicist Hans Christian Ørsted noticed that a compass needle moved when placed near a current-carrying wire. Electricity, it turned out, could create magnetism.

This revelation sparked a scientific revolution. Soon after, André-Marie Ampère, Michael Faraday, and James Clerk Maxwell began piecing together the puzzle of electromagnetism. They discovered that electric currents generate magnetic fields, that changing magnetic fields can produce electric currents, and that the two are inextricably linked. Their work laid the foundation for Maxwell’s equations—elegant laws that describe how electric and magnetic fields interact.

These laws are not just theoretical musings; they are the operating manual for nearly every piece of electrical technology you use. And they are the blueprint for the electric motor.

What Is an Electric Motor?

An electric motor is a machine that converts electrical energy into mechanical energy. In simple terms, it takes the flow of electric current and turns it into rotational motion. But this process is not just a matter of pushing electrons down a wire and getting movement out the other end. It’s a carefully choreographed interaction of magnetic fields, electrical currents, and Newton’s laws of motion.

At its core, an electric motor consists of two main components: the stator and the rotor. The stator is the stationary part that provides a constant magnetic field. The rotor is the rotating part that interacts with this field. When electric current flows through coils of wire on the rotor, it generates its own magnetic field. This field interacts with the magnetic field of the stator, producing a force that causes the rotor to spin.

But how exactly does this interaction produce motion? Why does the rotor turn instead of just vibrating or heating up? The answer lies in a fundamental principle of physics: the Lorentz force.

The Lorentz Force: Where Electricity Meets Magnetism

The Lorentz force is the key to understanding how electric motors produce motion. Named after Dutch physicist Hendrik Lorentz, this force describes how a charged particle—like an electron—experiences a force when moving through a magnetic field. Specifically, the force is perpendicular to both the magnetic field and the direction of the particle’s velocity.

This cross-product nature of the force means that the motion isn’t linear—it’s rotational. Imagine holding your right hand with your thumb pointing in the direction of the current, your fingers in the direction of the magnetic field, and your palm facing the direction of the resulting force. This “right-hand rule” tells you the direction of the force on the wire, and ultimately, the direction of motion of the motor.

In an electric motor, coils of wire are arranged on the rotor so that when current flows through them, the Lorentz force acts on the wires, causing the rotor to spin. The trick is to continuously change the direction of the current so that the rotor keeps turning in the same direction. This is where the commutator comes in.

The Commutator and Brushes: Keeping the Motion Alive

In direct current (DC) motors, the commutator is a split ring that reverses the direction of the current in the rotor coils every half turn. This ensures that the magnetic poles of the rotor keep pushing and pulling against the stator’s field in a consistent direction, keeping the rotor spinning.

The brushes are pieces of conductive material—usually graphite—that press against the commutator and supply current from the external power source. As the rotor turns, the commutator segments pass under the brushes, switching the current and maintaining the rotational motion.

Without the commutator and brushes, a DC motor would jerk to a halt every half-turn, as the magnetic forces would reverse and cancel out the motion. This ingenious mechanical switch keeps the dance of electricity and magnetism going, converting electrical energy into a continuous, smooth rotation.

In alternating current (AC) motors, the mechanism is slightly different. Instead of using a commutator to reverse the current, the alternating nature of the AC supply itself changes the direction of the current at regular intervals. These motors often use a rotating magnetic field generated by the stator to induce current in the rotor, causing it to turn.

Types of Electric Motors: A Diverse Electromagnetic Family

Electric motors come in many shapes and sizes, each designed for specific applications. Some are tiny, spinning the fans inside your laptop, while others are enormous, driving industrial machinery. But they all rely on the same electromagnetic principles.

DC motors are simple and controllable, ideal for applications where variable speed and torque are needed, such as in robotics and electric vehicles. AC motors, particularly induction motors, are rugged and efficient, commonly used in household appliances and factory equipment.

There are also stepper motors, which move in precise increments and are used in 3D printers and CNC machines. And brushless DC motors, which use electronic controllers instead of mechanical brushes and are favored in drones, hard drives, and electric bicycles for their efficiency and longevity.

Each of these motors uses the interplay of current and magnetic field, but the design tweaks—number of poles, winding configuration, rotor type—tailor the motor’s performance for its task.

Magnetic Fields and Field Lines: Visualizing the Invisible

To truly grasp how electric motors work, it helps to visualize magnetic fields. These invisible forces surround magnets and current-carrying wires, forming loops that curve from the north to the south pole of a magnet. These lines are not just conceptual—they represent the direction and strength of the magnetic force at every point in space.

When a wire carrying current is placed in a magnetic field, the field lines interact with the wire’s own magnetic field, creating a push or pull. If the wire is shaped into a loop or coil, the forces on different segments combine to create a torque—a turning force.

Electric motors exploit this principle by arranging many coils around the rotor, maximizing the torque generated by the interaction of fields. The more turns of wire, the stronger the magnetic field produced, and the greater the force on the rotor.

Energy Transformation: From Electrons to Motion

An electric motor is a marvel of energy transformation. It takes the potential energy of electric charges (voltage) and turns it into kinetic energy (motion). This process is governed by the law of conservation of energy, which states that energy cannot be created or destroyed, only transformed.

When current flows through the motor’s coils, it creates magnetic fields that do work on the rotor, causing it to spin. The energy used to move the rotor comes from the electrical energy supplied by the power source. Some of this energy is lost as heat due to resistance in the wires and friction in the bearings, but the rest is converted into useful mechanical work.

Efficiency is a key concern in motor design. Engineers strive to reduce losses by using superconducting materials, improving magnetic core designs, and using advanced electronics to control the motor’s operation.

Electromagnetic Induction: The Motor as a Generator

Interestingly, electric motors can work in reverse. If you spin the rotor by hand, it will generate a voltage in the coils. This is the principle of electromagnetic induction, discovered by Faraday. It’s the same principle behind generators and dynamos, where mechanical energy is converted into electrical energy.

This duality means that many devices can function both as motors and generators. In electric cars, for instance, regenerative braking systems use the motor as a generator to convert the car’s kinetic energy back into electrical energy during braking, recharging the battery and improving efficiency.

Motor Control Systems: The Brain Behind the Motion

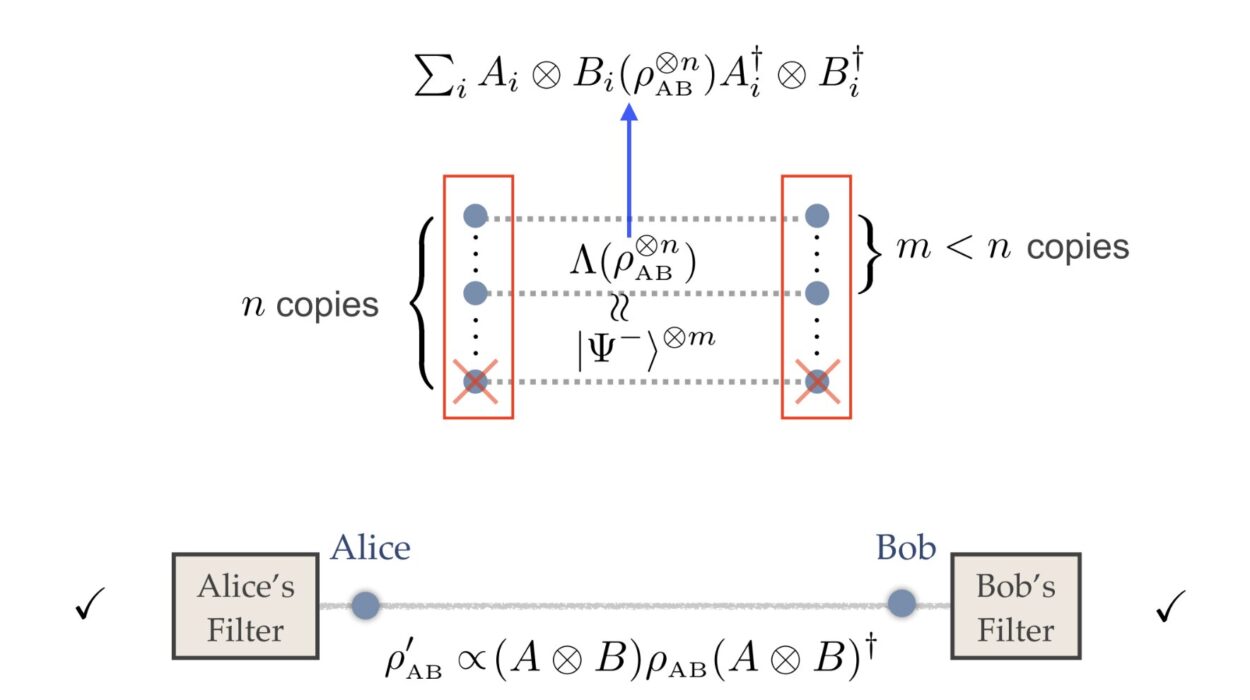

While the physics of electric motors is rooted in the interactions of currents and fields, the real-world application demands precise control. Motor control systems are the electronic brains that determine how fast a motor spins, how much torque it produces, and how efficiently it uses energy. Without control systems, electric motors would be little more than spinning hunks of metal.

In simple applications, like a fan or a drill, motor control might be limited to an on-off switch or a basic variable resistor. But in more sophisticated systems—such as electric vehicles, robotics, and CNC machines—control systems must dynamically adjust voltage, frequency, and current to optimize performance under varying loads and conditions.

One key component in these systems is the inverter. In AC motors, the inverter converts direct current from a battery into alternating current with precisely controlled frequency and amplitude. This allows engineers to finely tune the speed and torque of the motor, which is essential for applications like Tesla vehicles or industrial robots.

Another important control strategy is field-oriented control (FOC), sometimes called vector control. This technique transforms the motor’s magnetic field into a rotating reference frame, allowing precise regulation of torque and flux independently. FOC systems are complex but allow for smooth, efficient operation across a wide range of speeds—making them ideal for high-performance applications.

Control systems also involve sensors—such as Hall-effect sensors and encoders—that measure the rotor’s position, speed, and direction. These feedback signals are fed into microcontrollers or digital signal processors (DSPs), which execute algorithms in real-time to maintain optimal performance. The result is a motor that not only spins, but thinks.

The Role of Materials: Copper, Iron, and Rare Earths

The efficiency and power of an electric motor depend heavily on the materials from which it is built. Copper, for example, is the preferred conductor for motor windings because of its low electrical resistance. The less resistance there is, the less energy is lost as heat, and the more efficient the motor becomes.

Iron, or more precisely silicon steel, is used in the stator and rotor cores to guide the magnetic field lines. The silicon content helps reduce energy losses due to hysteresis and eddy currents—subtle effects that arise from the changing magnetic fields within the metal. These losses may be small, but over millions of rotations, they add up.

Permanent magnets are also crucial in many motor types, especially brushless DC motors and some AC synchronous motors. These magnets create a constant magnetic field without requiring current, improving efficiency and reducing size. However, high-performance magnets often require rare earth elements like neodymium and dysprosium—materials that are expensive and geopolitically sensitive.

Engineers are constantly searching for alternatives: ferrite magnets, advanced composite materials, and new cooling techniques that allow for higher power densities without overheating. The frontier of motor design is as much about materials science as it is about electromagnetism.

Real-World Applications: Electric Motors Everywhere

Electric motors are the unsung heroes of the modern world. Without them, our lives would grind to a halt—literally. They’re embedded in almost every technology we use, quietly converting electric pulses into useful work.

In your home, motors are found in appliances like refrigerators, air conditioners, vacuum cleaners, and washing machines. Your computer has motors in its cooling fans and hard drive (if it’s not solid-state). Even your toothbrush may contain a tiny vibrating motor.

In transportation, electric motors are revolutionizing the industry. Electric cars, buses, trains, and even aircraft are being propelled by efficient, high-power motors. Tesla’s induction and permanent magnet motors have become case studies in advanced motor engineering, using custom control software and precision manufacturing to achieve extraordinary performance.

In industry, motors power conveyor belts, robotic arms, pumps, compressors, and CNC tools. In agriculture, they drive irrigation systems and grain elevators. In medicine, they operate surgical tools and hospital beds. Wherever something moves with electricity, there’s a motor at work.

And then there’s miniaturization. Tiny motors, only millimeters across, are used in cameras, hearing aids, and haptic feedback systems. These micro and nano-scale motors represent the cutting edge of engineering, where traditional laws of physics meet quantum effects.

The Quantum Perspective: Electromagnetism at the Smallest Scales

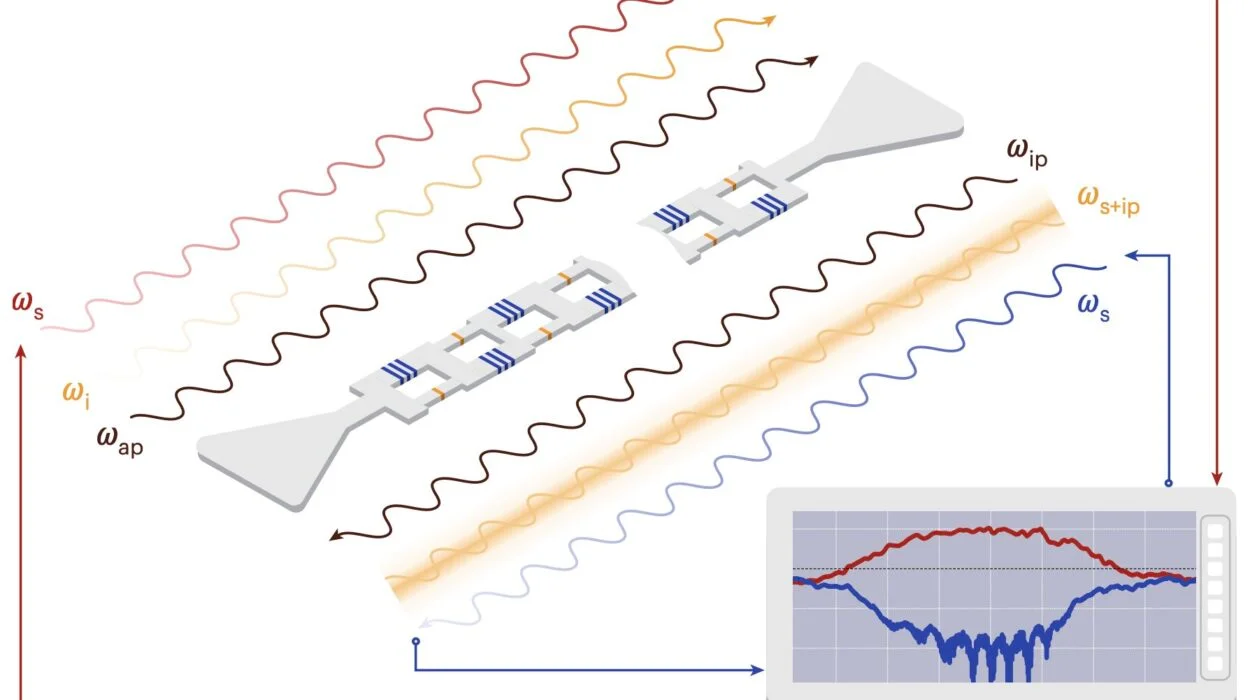

While Maxwell’s equations provide a complete and accurate description of classical electromagnetism, they are ultimately approximations of a deeper reality—one described by quantum electrodynamics (QED). QED is the quantum field theory that explains how light and matter interact, and it lies at the heart of our understanding of electromagnetism.

In QED, the electromagnetic field is quantized into particles called photons. When an electric current flows through a wire, it’s not just a stream of electrons bumping into atoms—it’s a quantum dance of fields and particles exchanging virtual photons. The magnetic field around a wire isn’t just a pattern of invisible lines—it’s the collective effect of countless photon exchanges at the subatomic level.

This quantum view doesn’t change how electric motors are built, but it deepens our understanding of why they work. The torque that spins a motor is the macroscopic result of trillions of quantum events—electrons responding to forces mediated by the electromagnetic field.

There’s also the quantum spin of electrons, which contributes to magnetism itself. The magnetic fields used in motors arise in part from the spin alignment of electrons in the material. Without spin, permanent magnets wouldn’t exist. So, the next time you see a motor spinning, remember: you’re witnessing quantum phenomena scaled up to human proportions.

Innovation and the Future: Where Motors Are Going

Electric motors have come a long way since Faraday’s first spinning wire. Today’s motors are more efficient, more powerful, and more precise than ever before. But the future holds even more promise.

Researchers are developing superconducting motors that eliminate electrical resistance entirely, achieving near-perfect efficiency. These motors require cryogenic temperatures but are being explored for applications like maglev trains and advanced propulsion systems.

There’s also a push for axial flux motors—motors where the magnetic field runs perpendicular to the rotor, rather than along its axis. These motors are flatter, lighter, and often more efficient than traditional radial designs. They could be game-changers for electric aircraft and high-performance vehicles.

In robotics, soft motors that mimic the elasticity of muscles are opening doors to machines that move more like living creatures. These use shape-memory alloys, electroactive polymers, or magnetic fluids to create motion without rigid parts.

Artificial intelligence is also making its way into motor control. Smart motors equipped with sensors and AI can diagnose themselves, adapt to different loads, and learn to optimize performance over time. These intelligent systems are poised to transform everything from manufacturing to healthcare.

And then there’s sustainability. With growing concern over the environmental impact of rare earth mining and energy use, engineers are exploring ways to build motors from recyclable materials, improve end-of-life recovery, and design systems that last longer and use less energy.

Conclusion: The Elegance of Electromagnetic Motion

The electric motor is more than a tool—it’s a symphony of physics, engineering, and innovation. Born from the unification of electricity and magnetism, perfected by generations of inventors and scientists, it now powers the world in ways we often take for granted.

Its operation, at once invisible and indispensable, embodies some of the most beautiful principles in physics. From the Lorentz force and magnetic fields to quantum spin and electromagnetic waves, the motor translates abstract equations into tangible, everyday motion.

Understanding how an electric motor works is like peeling back the surface of the modern world to reveal the clockwork of nature beneath. It reminds us that even the most ordinary technologies are powered by extraordinary ideas—and that in every hum of a fan, every spin of a wheel, and every beat of a robotic heart, there lies the elegant power of electromagnetism in motion.