The idea of humans living on Mars has captured imaginations for decades. From science fiction novels to ambitious plans by billionaires and space agencies, the red planet beckons as a new frontier for exploration and settlement. But moving from dream to reality is far from simple. While we can envision domed habitats and bustling colonies, the raw materials to build them present a profound challenge. Sending metal and concrete from Earth is not just expensive—it is almost unimaginable. NASA’s Perseverance Rover, for instance, cost roughly US$243 million to transport just one ton to the Martian surface. Multiply that by the scale of a human settlement, and the numbers become staggering.

For scientists like Dr. Deddy Nababan, the solution lies not in hauling resources across interplanetary space but in using what is already there. The surface of Mars, with its dusty red soil known as regolith, may hold the keys to creating the very metals needed for building a Martian civilization.

In-Situ Resource Utilization: Mining the Red Planet

The concept Dr. Nababan champions is called in-situ resource utilization (ISRU). At its core, ISRU is about working with local resources instead of relying on Earth shipments. “Sending metals to Mars might be feasible, but it’s not economical,” he explains. “Can you imagine bringing tons of metals to Mars? It’s just not practical. Instead, we can use what’s available on Mars.”

This approach transforms the problem of logistics into an opportunity for ingenuity. By extracting and refining metals directly from Martian regolith, scientists hope to establish self-sufficient production systems on the planet—a Martian foundry capable of providing the structural materials essential for life beyond Earth.

Astrometallurgy: Forging Metals in Space

Swinburne University of Technology’s astrometallurgist Professor Akbar Rhamdhani works closely with Dr. Nababan to explore this idea. Their focus is astrometallurgy, the science of making metals in extraterrestrial environments. Mars offers some surprisingly favorable conditions for this process. Its soil contains iron-rich oxides, while its thin atmosphere provides carbon—a natural reducing agent needed to transform these oxides into usable metals.

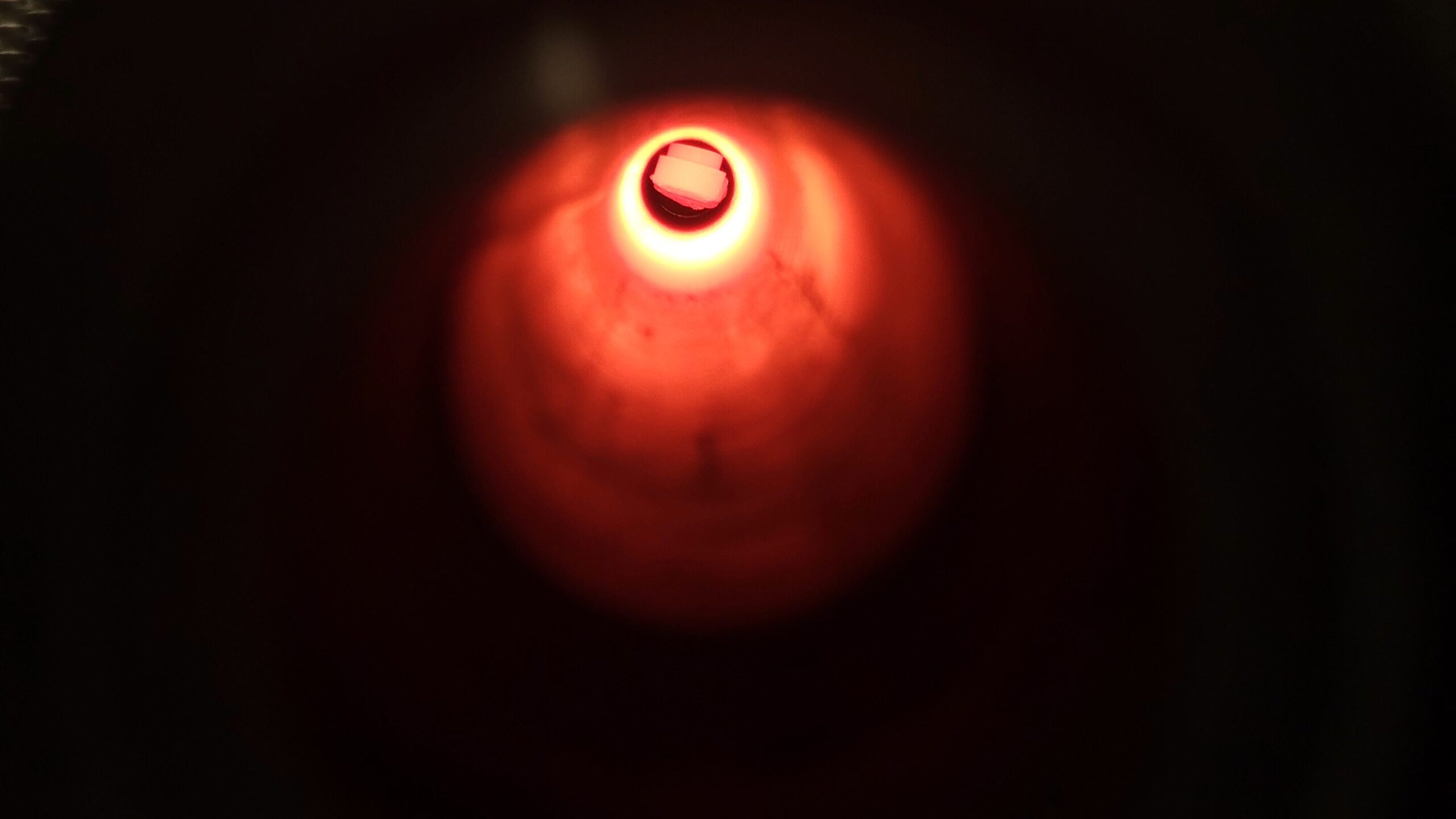

Since we cannot yet run large-scale experiments on Mars itself, the team uses Martian regolith simulants, artificial materials that closely mimic the composition and behavior of Martian soil. Experiments replicate Martian surface pressure and heating conditions to determine how metals might be extracted and processed off-world. These tests have already produced promising results: pure iron forms at approximately 1,000°C, and liquid iron-silicon alloys appear around 1,400°C. At high enough temperatures, the metals coalesce into a single droplet, just as they would in terrestrial smelting operations.

Turning Waste into Wealth

Beyond simply producing metals, the research emphasizes efficiency and sustainability. Collaborating with Dr. Mark Pownceby at CSIRO, the team is exploring ways to achieve zero-waste metallurgy. By-products from the smelting process could be repurposed for construction, shielding, or other industrial uses, creating a self-contained cycle of resource utilization.

This philosophy mirrors some of the most innovative developments on Earth, where sustainability and recycling are increasingly critical. In space, where resources are limited and resupply missions are costly, such efficiency becomes a necessity.

The Cost of Launch and the Promise of ISRU

Rocket launches are extraordinarily expensive, and every kilogram sent into space adds to the financial and logistical burden. Even with declining launch costs, Mars colonization will demand massive quantities of building materials. ISRU offers a transformative solution, potentially reducing dependence on Earth and enabling human settlements that are genuinely sustainable.

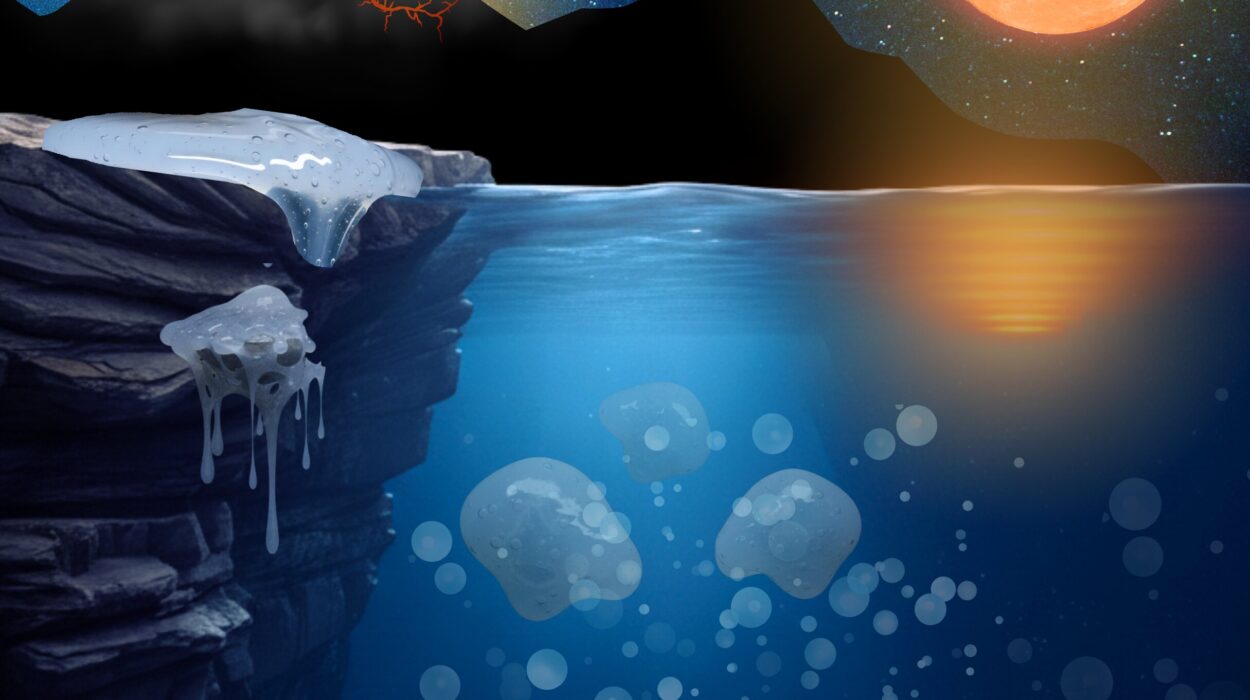

The success of ISRU has already been demonstrated in small but remarkable ways. NASA’s MOXIE experiment aboard the Perseverance rover produced breathable oxygen using only the carbon dioxide in the Martian atmosphere—a historic first step in off-world resource utilization. Producing metals directly on Mars represents the next giant leap, one that could enable everything from habitat shells to excavation machinery built entirely from local materials.

Challenges and the Road Ahead

Despite the promise, significant challenges remain. Scientists must understand how Mars-made alloys behave over time in the planet’s extreme environment. Differences in temperature, radiation, and dust could affect their strength and longevity. Moreover, scaling up laboratory experiments to industrial levels on Mars will require innovative engineering solutions and collaboration across multiple disciplines, including mining, metallurgy, robotics, and geology.

Professor Rhamdhani and his colleagues are preparing for these challenges through international engagement and education. Recent workshops in South Korea brought together experts in astrometallurgy, fostering global interest and collaboration. As Dr. Nababan notes, “To make it happen, we’re going to need experts from many fields—mining, engineering, geology, and much more.”

Beyond Mars: Benefits for Earth

The potential of astrometallurgy extends beyond Mars. By learning to extract and refine metals in extreme conditions with minimal waste, scientists hope to improve metallurgical processes on Earth. Innovations developed for space could lead to more efficient, sustainable manufacturing here, offering benefits to human life long before the first Martian colony is built.

In this way, the quest to inhabit another planet becomes a catalyst for progress at home. Space exploration and practical metallurgy are not separate endeavors—they are intertwined pursuits, each pushing the other toward greater achievement.

Humanity’s Next Frontier

The vision of humans living on Mars is no longer confined to science fiction. It is an unfolding scientific and engineering challenge, one that demands imagination, rigor, and collaboration. Astrometallurgy and ISRU exemplify the kind of ingenuity that will make this dream possible: turning dust into steel, soil into shelter, and alien terrain into a livable environment.

As Dr. Nababan reflects, this work is about more than exploration. It is about creating tools, knowledge, and processes that can ultimately improve life on Earth. In seeking to make metal on Mars, humanity is, in a very real sense, forging the future—on another world, and in the process, back home as well.

More information: Deddy C. Nababan et al, Iron (alloy) extraction on Mars through carbothermic reduction of regolith: a thermodynamic assessment and experimental study, Acta Astronautica (2025). DOI: 10.1016/j.actaastro.2025.05.005

Deddy C. Nababan et al, Metals extraction on Mars through carbothermic reduction: Mars regolith simulant (MGS-1) characterization and preliminary reduction experiments, Acta Astronautica (2025). DOI: 10.1016/j.actaastro.2025.04.050