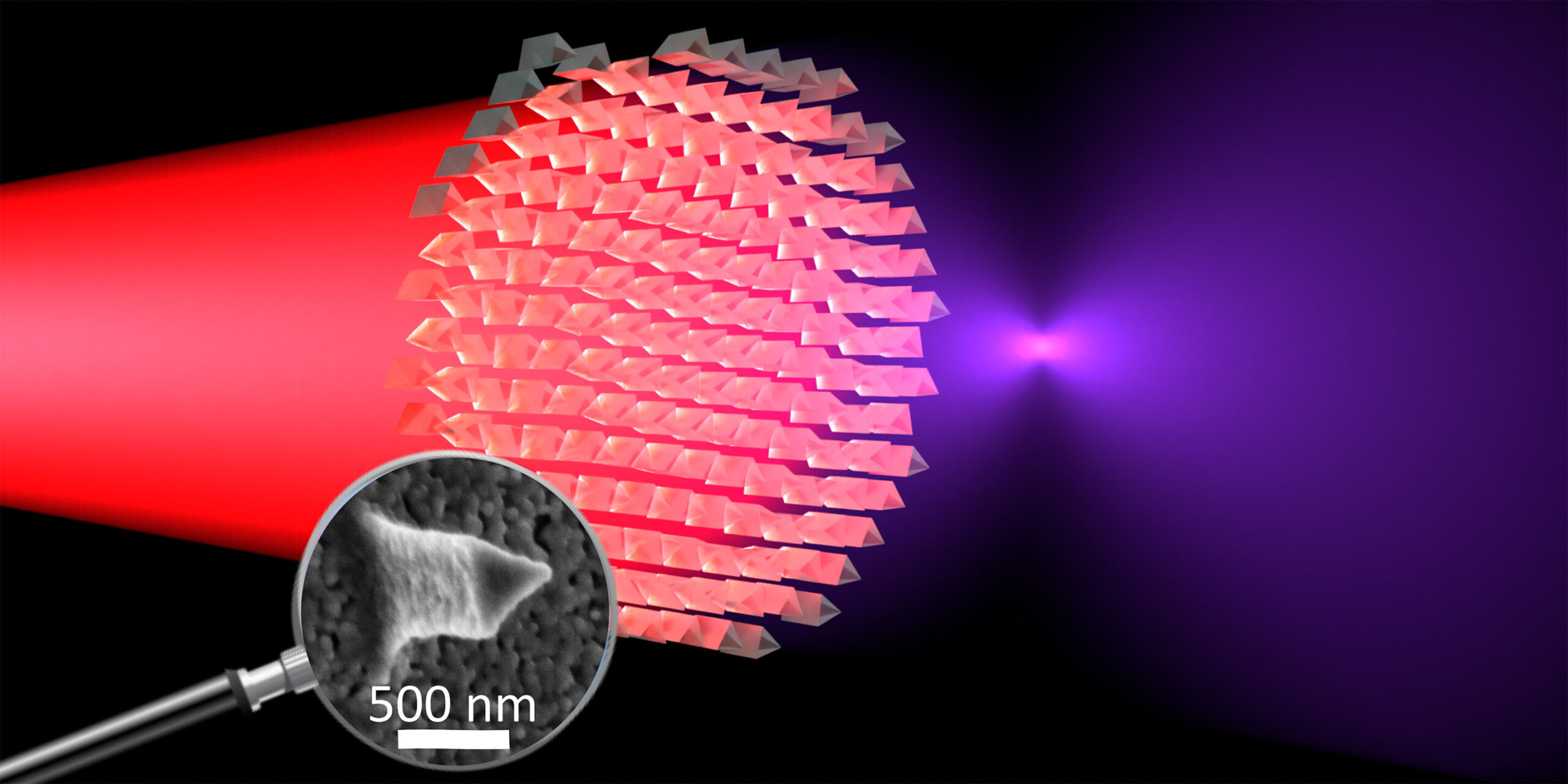

In the heart of Switzerland, where tradition and technology blend seamlessly, a group of physicists at ETH Zurich have quietly cracked open a new realm in optics. With precision tools and a visionary mindset, they’ve developed an ultrathin metalens that doesn’t just focus light—it transforms it. By halving the wavelength of incident infrared light, these pioneering scientists have managed to generate visible light from the invisible, using a lens smaller than a grain of dust. This leap forward, published in the journal Advanced Materials, is more than a technological marvel—it is a rewriting of the rules of light itself.

The Age-Old Lens, Reimagined

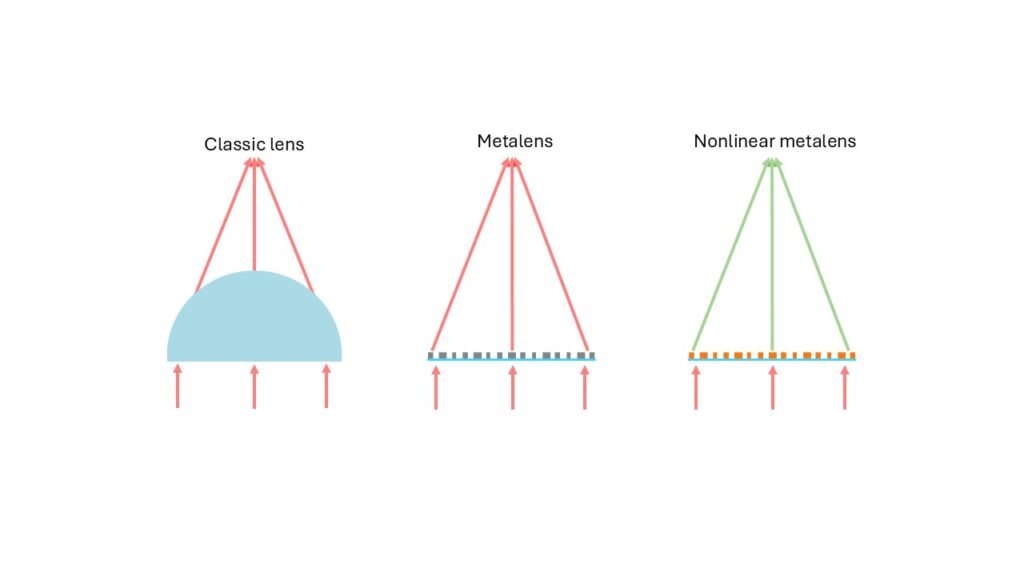

For centuries, lenses have been our window to the world, from Galileo’s telescope peering into the heavens to the camera lens capturing your morning selfie. They work by bending and focusing light through curved glass surfaces. But their bulky nature has always been a bottleneck, especially in our age of miniaturization.

The modern smartphone camera, although sleek and sophisticated, is still beholden to the classical laws of optics. The reason that camera bump protrudes from the back of your phone? It’s because even the most powerful digital sensor can’t escape the need for thick, curved lenses to bring light to a sharp focus. That’s a physical limit—until now.

Over the past decade, a revolution has been stirring in optics. Instead of relying on curved surfaces, scientists have turned to flat optics, specifically metalenses—a term that may soon become as familiar as “pixel.” These lenses achieve the same light-focusing effect using arrays of nanostructures carved into a surface so thin it’s almost imperceptible to the human eye.

The Rise of Metasurfaces

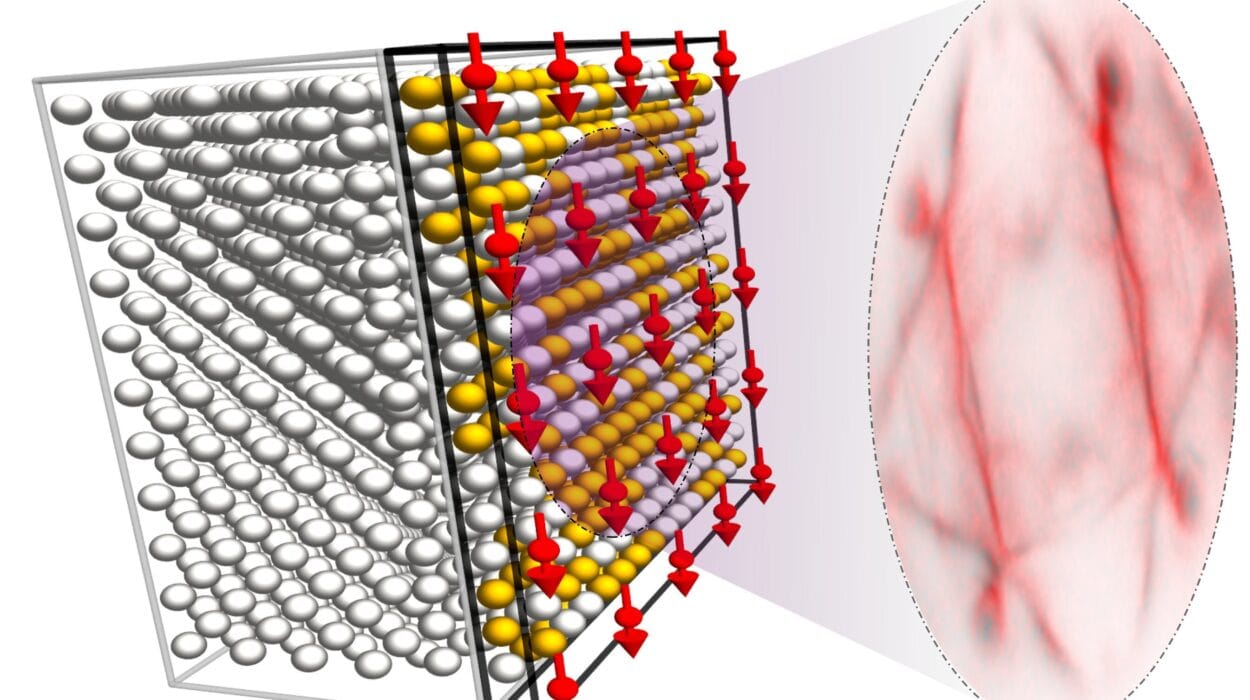

A metalens isn’t a piece of glass. It’s a carefully arranged terrain of nanostructures, often no taller than 100 nanometers—thousands of times thinner than a human hair. These nanoscale pillars and ridges manipulate light with uncanny precision, bending, delaying, and twisting it in ways that conventional optics never could.

This field, known as metasurfaces, has opened a playground where physicists can engineer the interaction between light and matter at scales once deemed impossible. By changing the shape, size, and spacing of these nanostructures, they can build flat optical components that are lighter, smaller, and often more versatile than their glass-based ancestors.

But metasurfaces are more than just size savers. When paired with materials possessing special optical properties, they can step beyond the bounds of linear optics and into a stranger, richer realm.

Unlocking the Nonlinear Realm

In everyday life, light behaves in predictable ways—it reflects, refracts, and sometimes disperses. This is linear optics. But crank up the intensity, and light begins to break the rules. It starts to interact with itself and the medium it travels through in non-intuitive ways. This is nonlinear optics, and it’s where things get interesting.

One well-known nonlinear optical process is second harmonic generation—a phenomenon where light doubles its frequency (and therefore halves its wavelength). For instance, infrared light at 800 nanometers can be converted into visible light at 400 nanometers, shifting from invisible to violet. This principle underlies green laser pointers, where infrared light is converted into the brilliant green beam you see.

But making such nonlinear conversions typically requires large, high-quality crystals and elaborate setups—not something you can cram into a chip or smartphone. That’s what makes the ETH Zurich team’s new invention so radical. They’ve taken this powerful optical effect and packed it into a flat, nanostructured metalens made from lithium niobate—a material long prized in telecommunications for its robust nonlinear characteristics.

A Breakthrough in Material Engineering

Lithium niobate has long been a darling of the optics world. It’s stable, nonlinear, and used widely in electro-optic modulators. But its stability is a double-edged sword—it’s also stubbornly hard to sculpt at the nanoscale. That’s where the ETH Zurich team’s ingenuity shines.

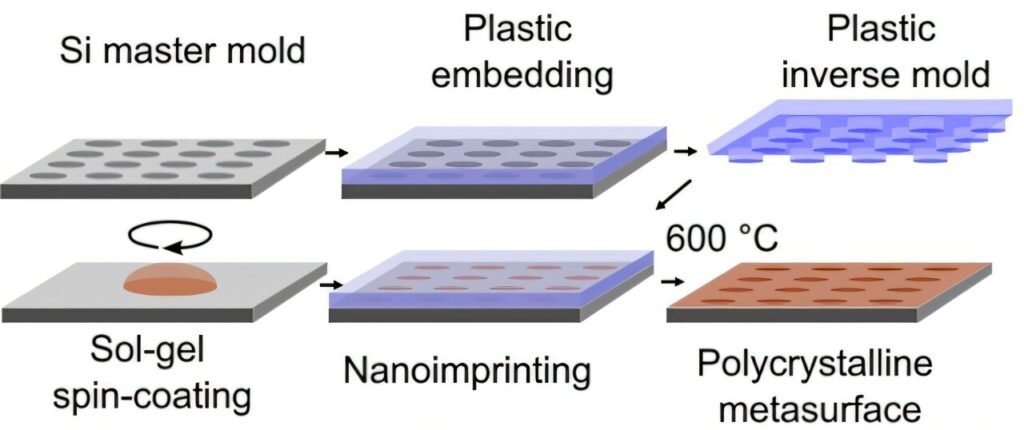

Led by Professor Rachel Grange of the Institute for Quantum Electronics, the researchers developed an innovative method to print lithium niobate nanostructures with incredible precision. The technique blends chemical synthesis with a clever stamping process, reminiscent of Gutenberg’s printing press—but instead of ink, they use a solution rich in lithium and niobium precursors.

As the liquid is stamped into shape and then fired at 600°C, it crystallizes into lithium niobate with the desired optical qualities. The result: a reusable mold for manufacturing high-precision, nonlinear metalenses, quickly and cost-effectively.

Doctoral student Ülle-Linda Talts, co-first author of the study, describes the process with a touch of awe: “It’s like printing lenses with magic ink. Once the heat hits, it becomes a crystal that bends and reshapes light in entirely new ways.”

Seeing the Invisible

The true magic of this ultra-thin lens lies in what it can do. Unlike traditional lenses that merely focus light, this lithium niobate metalens transforms it.

Send in infrared light with a wavelength of 800 nanometers—completely invisible to the human eye—and out comes a focused beam of visible violet light at 400 nanometers. All of this happens within a lens just hundreds of nanometers thick, engineered to funnel the light toward a precise focal point.

This is more than light redirection. It’s light conversion. And because the nonlinear optical effect isn’t constrained to a narrow frequency, it can be adapted to various wavelengths and applications. It’s a platform for reengineering light at will.

The Future in Focus

The implications are dazzling. Imagine compact night vision devices that need no batteries or bulky sensors, because they convert infrared to visible light using nothing more than a metalens. Or optical systems in autonomous vehicles that can better detect heat signatures from living beings and engines, without large thermal imaging arrays.

In secure communications, the ability to steer and transform light opens doors to new encryption techniques. In forensic science, ultra-sensitive, tunable lenses could detect trace compounds or biofluids invisible to the naked eye. Even in art and currency protection, metalenses could act as miniature security holograms impossible to counterfeit, readable only under specific light conditions.

Then there’s microscopy. High-resolution imaging often relies on ultraviolet or deep-UV light, which requires massive optical setups. Metalenses with nonlinear properties could drastically shrink that equipment, making it accessible to labs around the world. Imagine examining viruses, DNA strands, or semiconductor circuits with the fidelity of an electron microscope—using only a handheld device.

Printing the Future of Photonics

One of the most exciting aspects of this discovery isn’t just what the lens does—but how it’s made. The ETH Zurich team’s printing method allows for scalable, reproducible production. That’s the holy grail in photonics: not just developing a lab curiosity, but enabling manufacturing at the level of chips and smartphones.

With reusable inverse molds and a low-cost fabrication process, the team has overcome one of the biggest barriers in nonlinear optics—cost. This democratizes access to high-end optical components, enabling their integration into consumer electronics, wearables, and compact scientific tools.

It’s a case of form following function, and function following fantasy. The invisible is now visible. The bulky is now thin. The future of light may not be through curved glass, but across a landscape of invisible nanostructures imprinted on crystalline sheets.

Scratching the Surface of Light’s Potential

Metasurfaces—these wafer-thin, light-bending marvels—represent a young but explosive field. They’re born from the convergence of physics, materials science, nanotechnology, and even art. And according to Professor Grange, we’re only just beginning.

“We have only scratched the surface so far,” she says. “The combination of flat optics and nonlinear materials is a powerful one. We’re very excited to see how much impact this new, cost-effective technology will have in the years ahead.”

What began as a quiet tinkering with nanocrystals in a Zurich lab has opened a door to an entirely new way of seeing, sensing, and shaping the world. The metalens developed by Grange’s team doesn’t just focus light—it focuses the imagination on what’s possible when we reshape our fundamental tools.

In the coming decade, expect this innovation to ripple outward—from smartphones and sensors to quantum devices and beyond. After all, when we learn to bend light to our will, we begin to illuminate the very fabric of the universe itself.

Reference: Ülle‐Linda Talts et al, Scalable Lithium Niobate Nanoimprinting for Nonlinear Metalenses, Advanced Materials (2025). DOI: 10.1002/adma.202418957