In the vast stillness of deep space, even the smallest movements matter.

NASA’s upcoming Habitable Worlds Observatory—a next-generation space telescope designed to search for signs of life on exoplanets—will need to stare at distant stars with extraordinary precision. To detect the faint light from Earth-sized planets orbiting faraway suns, the telescope must maintain stability with an accuracy that defies imagination: no more than 10 picometers of motion. For scale, that’s one-tenth the diameter of a single atom.

Achieving such stability is a challenge unlike any engineers have faced before. And yet, a curious, almost paradoxical new material might hold the key. It doesn’t expand when heated. It shrinks.

Meet ALLVAR Alloy 30, a remarkable metal developed through a collaboration between NASA and Texas-based materials company ALLVAR. Unlike nearly every material on Earth, this alloy exhibits negative thermal expansion (NTE)—it gets shorter as temperatures rise and expands as they fall. While counterintuitive, this property could be the missing piece in a puzzle that stretches across the stars.

The Heat Problem in Cold Space

Telescopes, especially those that venture into the frigid vacuum of space, are vulnerable to one universal truth: materials expand and contract with temperature changes. This behavior can cause microscopic distortions in the structure of a telescope, blurring its vision just enough to make distant planets undetectable.

Today’s space telescopes like the James Webb Space Telescope and the forthcoming Nancy Grace Roman Space Telescope use advanced materials to mitigate these effects—but the requirements for the Habitable Worlds Observatory go even further. Scientists estimate it must be 1,000 times more stable than anything launched before.

To reach that unprecedented level of stability, engineers must develop entirely new solutions. That’s where ALLVAR’s alloy steps in.

A Metal with a Mind of Its Own

Most metals expand when heated. Aluminum, for example, grows by 23 parts per million per degree Celsius (ppm/°C). That means a one-meter-long rod of aluminum will get 0.023 millimeters longer for every 1°C rise in temperature—a change big enough to ruin the precision of a space telescope.

But ALLVAR Alloy 30 does the opposite. At room temperature, it shrinks by 30 ppm/°C. A one-meter rod shortens by 0.003 millimeters when warmed—a small but powerful shift when used alongside traditional materials.

By combining materials that expand with heat (like titanium or Invar) with ALLVAR’s NTE alloy, engineers can create self-balancing structures that remain stable across temperature changes. When one part expands, the other contracts, keeping the whole system locked in place.

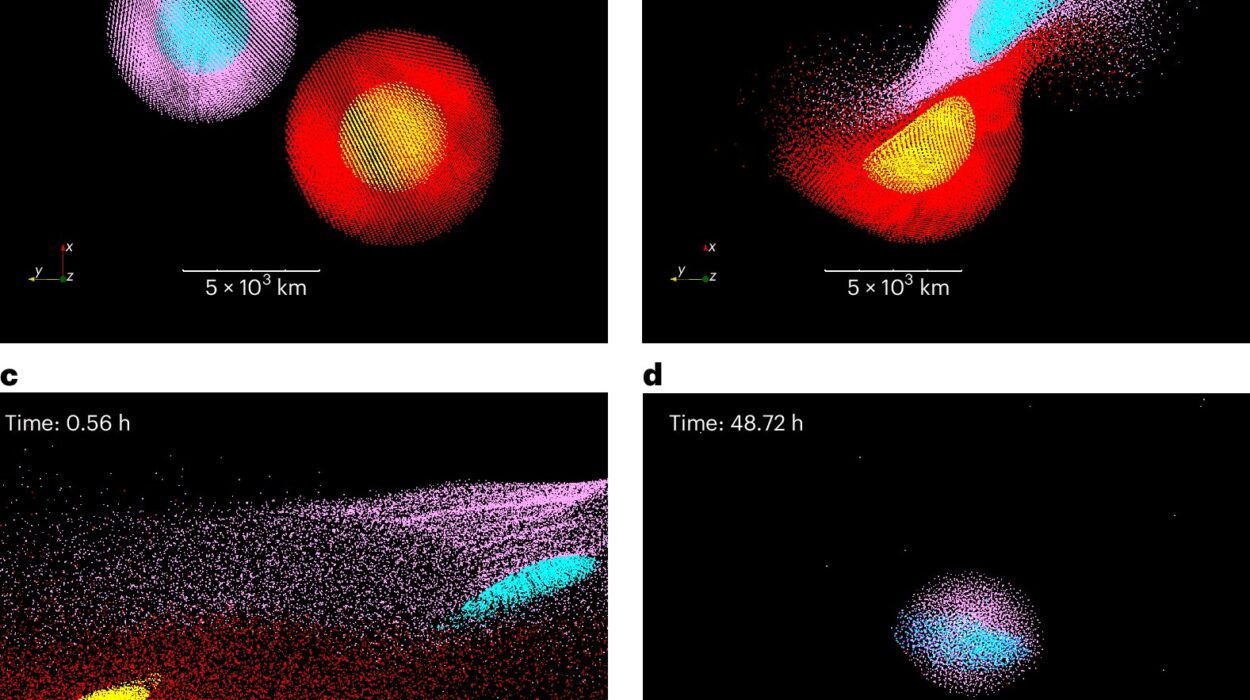

The Hexapod That Stood Still

To prove this concept, the ALLVAR team, in collaboration with NASA’s Marshall Space Flight Center and Jet Propulsion Laboratory, constructed a test structure known as a hexapod—a six-legged frame designed to hold two telescope mirrors in perfect alignment.

Each leg of the hexapod included Ti6Al4V flexures (a titanium alloy), Invar components (known for low expansion), and a connecting tube made from ALLVAR Alloy 30. As the structure heated and cooled, the positive expansion of titanium and Invar was perfectly canceled out by the shrinking NTE alloy.

The result? A telescope support system so stable it achieved 11 picometers per square root hertz (pm/√Hz)—just a whisker away from NASA’s 10 picometer target for the Habitable Worlds Observatory.

Even more impressive, the structure withstood a 28°C temperature swing with less than a 5-nanometer change in the shape of the mirrors. In telescope terms, that’s like landing a spacecraft on the Moon with centimeter accuracy—while blindfolded.

Born in the Lab, Built for the Stars

The story of ALLVAR’s alloy began with fundamental research, supported by NASA’s Small Business Innovation Research (SBIR) program. Early experiments showed the alloy’s potential, but it took years of development to refine its properties, test its reliability, and scale production from lab to commercial levels.

Today, ALLVAR Alloy 30 is not only being considered for future NASA telescopes—it’s already being used in projects bound for the Moon.

The alloy was recently integrated into the Lunar Surface Electromagnetics Experiment-Night (LuSEE Night), a payload developed by UC Berkeley’s Space Science Lab and slated to launch aboard Firefly Aerospace’s Blue Ghost Mission 2. By using NTE components in its thermal switches, the system gained both higher efficiency and smaller size—a critical combination for space missions where every gram and watt counts.

More Than a Telescope Tool

While the search for alien life may be its most exciting frontier, ALLVAR Alloy 30’s applications extend far beyond astronomy.

Thermal mismatches cause problems in a wide range of technologies—from bolted joints on satellites to sensitive optics in medical scanners. ANY precision instrument that changes temperature is at risk of warping, shifting, or losing alignment.

By introducing NTE washers and spacers made from the alloy, engineers can now maintain consistent pressure, alignment, and performance, even across massive temperature swings. These components are now commercially available and already improving designs in aerospace, defense, quantum computing, and even nuclear engineering, where stability can literally be a matter of life and death.

ALLVAR is also working on a new alloy with tunable expansion properties, capable of matching the expansion of other materials or achieving zero expansion altogether. Such materials could revolutionize not only spaceflight, but manufacturing, imaging, communications, and beyond.

A Clearer View of Distant Worlds

For now, though, the alloy’s most poetic promise remains in space.

To detect the gases of alien atmospheres, NASA’s future telescopes will need to stare past blinding starlight, extracting faint planetary signals from a billion-to-one contrast. The mirrors must not tremble. The frames must not shift. Even the smallest distortion could blur away the evidence of a habitable world.

Thanks to ALLVAR Alloy 30, that vision is closer than ever.

As NASA engineers plan the Habitable Worlds Observatory, they now have in their toolbox a material that doesn’t play by the normal rules of physics. A metal that shrinks when it should expand. A partner to the stars that dances in balance with the universe’s deepest rhythms.

If life exists on a planet orbiting another sun, it may be this strange alloy—quiet, stable, and stubbornly inverse—that helps us find it.