As the world transitions to renewable energy, the demand for lithium-ion batteries (LIBs) continues to rise. These batteries are integral to powering everything from electric vehicles (EVs) to grid storage systems, making them crucial in the fight against climate change. However, with the growing reliance on these batteries comes the challenge of securing the critical metals used to manufacture them—lithium, cobalt, nickel, and other essential elements. A recent study by Stanford University offers promising insights into a sustainable solution: recycling lithium-ion batteries.

This groundbreaking research, published in Nature Communications, reveals that recycling lithium-ion batteries significantly reduces the environmental impact compared to mining virgin metals. In fact, on a large scale, battery recycling could ease the geopolitical and physical insecurity surrounding the long-term supply of these critical minerals. This article dives deep into the findings of the study and the potential for a greener, more sustainable future of battery recycling.

The Need for Lithium-Ion Battery Recycling

Lithium-ion batteries have become the cornerstone of modern technology, especially as global efforts to curb carbon emissions focus on the electrification of transportation. However, the production of lithium-ion batteries relies heavily on several metals that are either scarce or concentrated in only a few regions of the world. For instance, lithium is mainly mined in Australia, Chile, and Argentina, while cobalt is primarily sourced from the Democratic Republic of the Congo. These materials are not only finite but are also subject to geopolitical risks, making the security of their supply a significant concern.

As demand for lithium-ion batteries increases, so does the need to address the environmental impacts associated with both mining new metals and disposing of spent batteries. Recycling provides a potential solution to this challenge, allowing us to recover valuable metals while reducing the environmental footprint of battery production.

Study Overview: Environmental Benefits of Recycling

The Stanford University study analyzed the environmental impacts of recycling lithium-ion batteries and compared them to the traditional methods of extracting metals through mining and refinement. The researchers assessed key environmental metrics such as greenhouse gas emissions (GHGs), water usage, and energy consumption.

The results were striking. According to the study, battery recycling emits less than half the GHGs of conventional mining and uses approximately one-fourth of the water and energy required for the extraction of new metals. Notably, the recycling process offers even greater environmental advantages when the materials come from defective scrap material produced by battery manufacturers, as opposed to discarded consumer batteries.

The study found that recycled scrap material—which comprised about 90% of the recycled supply—resulted in the following environmental impacts compared to traditional mining:

- 19% of the GHG emissions of mining and processing

- 12% of the water usage

- 11% of the energy use

In addition, although it was not directly measured, the study suggested that the reduced energy consumption from battery recycling also correlates with a decrease in other pollutants, such as soot and sulfur, which are commonly released during the mining and refining process.

The Importance of Location in Battery Recycling

While the environmental benefits of recycling are clear, the study also emphasized that the location of the battery recycling facility plays a significant role in determining its overall environmental impact. The source of electricity used by the recycling plant is one of the most critical factors.

For instance, in regions that rely heavily on electricity generated from fossil fuels, such as coal, the climate benefits of recycling are diminished. On the other hand, recycling plants located in areas where clean energy sources like hydropower, solar, or geothermal power the grid see a significant reduction in their carbon footprint.

The Stanford researchers used data from Redwood Materials, a leading battery recycling facility located in Nevada, which benefits from the clean energy mix in the western United States. This includes hydropower, solar, and geothermal energy, all of which contribute to a lower environmental impact. This suggests that selecting locations for future battery recycling plants that are powered by renewable energy is key to maximizing the benefits of recycling.

Transportation: A Key Factor in Sustainability

Another important consideration is transportation. The study noted that the transportation of materials—whether it be metals mined for new batteries or used batteries sent for recycling—can have significant environmental implications. For example, cobalt, a critical metal used in many lithium-ion batteries, is primarily mined in the Democratic Republic of the Congo. Once mined, the material is transported to China for refining, a journey that can span tens of thousands of miles. The mining of lithium similarly requires extensive transportation from countries like Australia and Chile to China for processing.

In contrast, the recycling process requires much shorter transportation distances. For instance, the study estimated that the transportation of used batteries to a recycling facility in California would average just 140 miles (225 kilometers). This is in stark contrast to the 35,000 miles (57,000 kilometers) typically associated with the mining and processing of metals like cobalt.

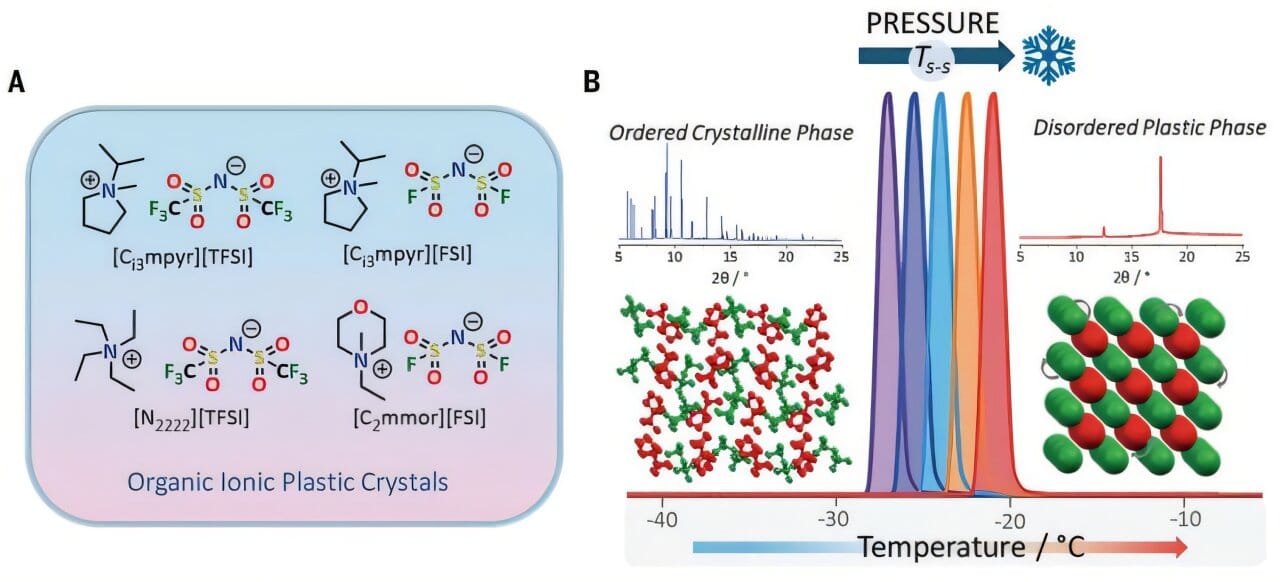

Innovations in Recycling Processes

One of the major advancements in battery recycling highlighted by the study is the innovative process used by Redwood Materials. The company has developed a patented method called reductive calcination, which requires much lower temperatures than traditional pyrometallurgical processes. Conventional pyrometallurgy, which is used to refine metals from mined ores, requires extremely high temperatures (above 2,550 degrees Fahrenheit or 1,400 degrees Celsius) and is very energy-intensive. In contrast, reductive calcination uses moderate temperatures and does not rely on fossil fuels, making it a much more sustainable option for metal recovery.

The use of reductive calcination also results in a higher yield of lithium, which is one of the most important and challenging metals to recover from spent batteries. This innovative process could set a new standard for the future of battery recycling, offering a more energy-efficient and environmentally friendly alternative to traditional methods.

Looking Ahead: Scaling Up Battery Recycling

Despite the promising results of the study, the researchers noted that the battery recycling industry is still in its infancy, and much work remains to be done. The demand for critical metals like lithium, cobalt, and nickel is expected to continue to rise as electric vehicle production increases. If current trends continue, the world could run out of these critical metals within the next decade. While it is likely that mining will continue to meet some of this demand, recycling offers a way to mitigate the environmental and supply chain risks associated with traditional mining.

The United States currently recycles around 50% of its lithium-ion batteries, a figure that is far lower than the 99% recycling rate for lead-acid batteries, which have been in use for decades. Lithium-ion batteries contain materials that have up to 10 times the economic value of lead-acid batteries, presenting a significant opportunity for the recycling industry.

To prepare for a future where more batteries are recycled, the researchers argue that it is essential to begin designing and scaling up recycling systems today. This includes investing in infrastructure, improving collection methods, and optimizing recycling technologies to ensure minimal environmental impact.

Conclusion: A Sustainable Future for Battery Recycling

The Stanford study provides compelling evidence that recycling lithium-ion batteries is not only environmentally beneficial but also essential to ensuring a sustainable supply of the critical metals needed for modern technology. By reducing the environmental footprint of metal extraction, recycling can help meet the growing demand for batteries while minimizing the adverse effects of mining.

As the global push for cleaner energy accelerates, battery recycling will play an increasingly important role in building a more sustainable and secure future. However, to fully realize the potential of recycling, continued innovation, investment in infrastructure, and careful consideration of location and energy sources will be crucial. The future of battery recycling is not just a technological challenge; it is a path toward a more circular, sustainable economy.

Reference: Michael L. Machala et al, Life cycle comparison of industrial-scale lithium-ion battery recycling and mining supply chains, Nature Communications (2025). DOI: 10.1038/s41467-025-56063-x