For decades, engineers have been trying to make robots move more like living creatures—fluid, flexible, and intelligent in their motion. But while nature evolved grace and adaptability through muscles, tendons, and nerves, human-made machines often remained stiff, mechanical, and cumbersome. Every time roboticists wanted to make a robot more agile, they added more motors, sensors, and control systems. The result was complexity—machines that could move impressively, but only at great cost in weight, energy, and control.

Now, a research team led by Dr. Lin Cao from the University of Sheffield’s School of Electrical and Electronic Engineering has found a way to flip this old logic on its head. Instead of adding more moving parts, they’ve taught robots to move smarter. Their groundbreaking work, published in Science Advances, introduces a new concept called Hysteresis-Assisted Shape Morphing (HasMorph)—a discovery that could change how we think about robotics forever.

The Beauty of a “Flaw”

Every mechanical system has imperfections, small quirks that engineers have traditionally tried to eliminate. One of those quirks is called hysteresis—a kind of mechanical “memory” where a material’s behavior depends not only on its current state but also on what it did before.

If you’ve ever turned a steering wheel and noticed that it doesn’t immediately spring back to center, or felt the subtle lag when gears change direction, you’ve experienced hysteresis. Most designers see it as inefficiency—a nuisance to be corrected. But Dr. Cao and his colleagues saw something different.

“What if hysteresis isn’t a problem?” Dr. Cao asked. “What if it’s a feature?”

This simple question led to a radical new way of thinking. Instead of fighting hysteresis, the team decided to use it. They realized that by harnessing this natural mechanical delay, robots could remember previous shapes, hold positions without constant control, and perform intricate, multi-step movements—all while using far fewer actuators.

From “More Motors” to “Smarter Motion”

In most robotic systems, more dexterity means more motors. Each motor—or actuator—controls one joint or one section of movement, much like strings on a puppet. The more strings you add, the more control you get—but also more complexity. The traditional approach is like building a machine with dozens of tiny muscles, each requiring its own commands.

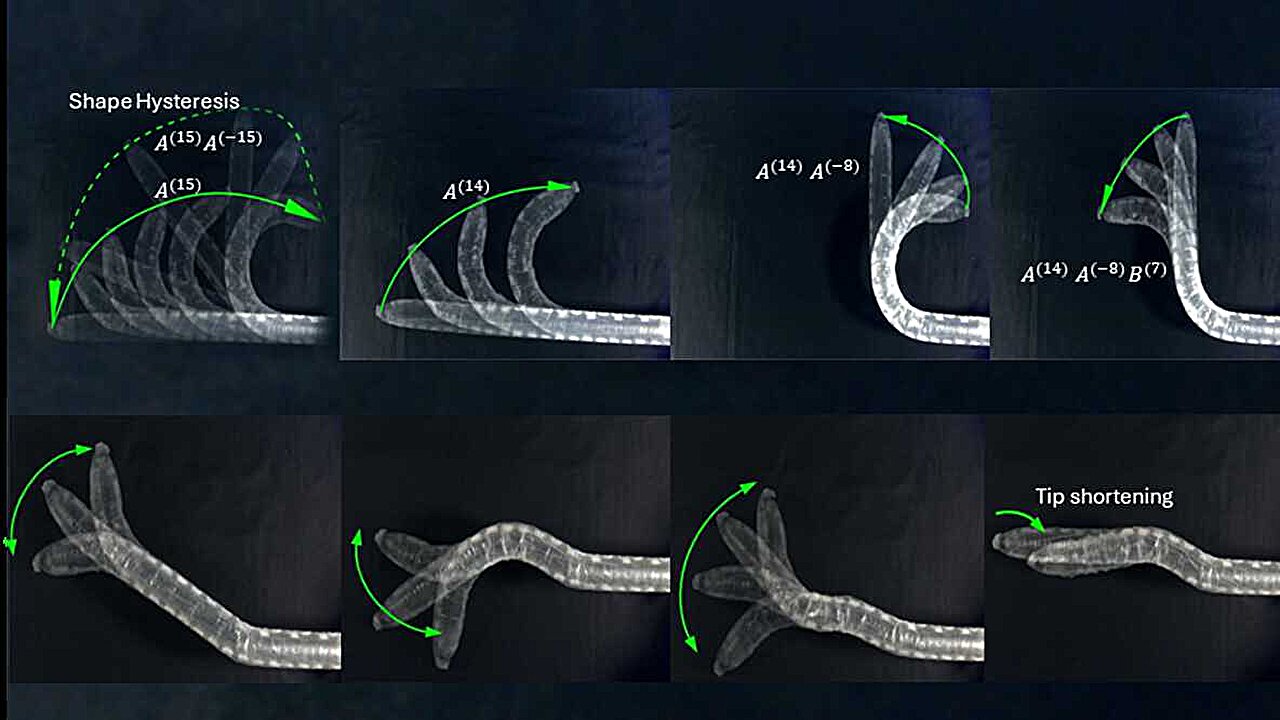

The HasMorph system breaks that rule completely. By exploiting hysteresis, Dr. Cao’s team created robots that can achieve a wide range of shapes and motions with only two tendons. These tendons pull and release sections of a soft robotic arm, and thanks to hysteresis, each section responds slightly differently depending on its past movements. The result is a robot that can move, bend, twist, and morph its body with a surprising level of precision—without the need for dozens of motors or complicated algorithms.

“More dexterous motion doesn’t have to mean more motors,” Dr. Cao explained. “It’s about designing smarter.”

This shift in thinking—seeing intelligence as something that can be embedded in the material itself, rather than just in the control software—marks a turning point in robotics design philosophy.

Three Breakthroughs in One Idea

The HasMorph concept isn’t just a clever trick; it represents three fundamental breakthroughs that could reshape the field of soft robotics.

First, the team turned hysteresis from a flaw into a feature. Instead of treating it as a source of error, they used it to achieve controllable, stable shape changes. The robot doesn’t need constant adjustment—it naturally holds its shape, just as a bent plant stem stays curved without continuous force.

Second, HasMorph introduces a new actuation paradigm. With only two tendons, the robot can independently control multiple bending sections, allowing for billions of potential configurations. This level of shape complexity, achieved with such simplicity, was previously thought impossible.

Third, and perhaps most dramatically, the researchers combined HasMorph with a soft growing robot—a design inspired by plants that extend their tips to explore their surroundings. By applying HasMorph to this structure, they created a robot that can “grow” forward, steer around obstacles, and even retract from the tip, following the exact path it took forward. This “follow-the-leader” motion has long been a dream in robotics, especially for applications where precise navigation through tight spaces is crucial.

Growing Robots That Think Like Nature

Imagine a robot that grows like a vine—pushing its way forward gently, adapting its shape as it encounters obstacles, choosing its direction with delicate precision. That’s exactly what HasMorph makes possible.

By combining soft, plant-like growth with intelligent shape memory, Dr. Cao’s robot can extend into confined or unpredictable environments—then retract safely, leaving no damage behind. This makes it ideal for exploring delicate spaces where traditional machines would fail, from medical procedures inside the human body to search-and-rescue missions in disaster zones.

It’s as if robotics has finally taken a lesson from evolution: efficiency doesn’t come from brute force, but from harmony between material, motion, and memory.

Transforming Medicine and Beyond

The implications of HasMorph are vast, reaching far beyond the laboratory.

In minimally invasive medicine, for example, HasMorph could enable the next generation of robotic endoscopes—thin, flexible devices that can travel inside the human body with unprecedented agility. These tools could navigate around vital organs without friction or trauma, reaching deep into the body with surgical precision.

“For patients, this could mean safer, less traumatic procedures,” said Dr. Cao. “A robot that can gently adapt to the body’s contours rather than force its way through.”

In search and rescue operations, HasMorph robots could crawl through collapsed buildings or rubble, bending and twisting through tight gaps to locate survivors. In industrial inspection, they could travel inside pipelines, engines, or structural cavities that are too narrow or dangerous for humans or conventional machines.

And because the system relies on fewer motors and simpler control mechanisms, these robots are lighter, cheaper, and easier to maintain—opening the door for real-world deployment in places where sophisticated robots were once impractical.

A Paradigm Shift in Robotic Thinking

Perhaps the most profound impact of HasMorph isn’t mechanical—it’s philosophical. It challenges the long-standing assumption that complexity requires complexity. Instead, it shows that true sophistication can arise from simplicity when you understand how to work with the natural properties of materials, rather than against them.

By embracing hysteresis—a phenomenon long viewed as a limitation—Dr. Cao and his team have demonstrated the power of thinking differently. It’s a reminder that innovation often comes not from adding more, but from seeing the familiar in a new light.

This mindset could inspire a new generation of roboticists to look beyond circuits and motors, to study the soft, subtle, and often unpredictable behavior of materials as partners in design. After all, nature has been perfecting this art for billions of years.

Toward Smarter, Softer, More Human Machines

The robots of the future may not clank and whir like the machines of science fiction. They may grow, bend, and breathe like living organisms—graceful, adaptable, and alive in motion. The HasMorph system brings us one step closer to that vision, blending engineering with biology in ways once thought impossible.

In a world where robotics often races toward complexity, Dr. Lin Cao’s discovery is a quiet revolution. It reminds us that intelligence isn’t always about more—it’s about balance, memory, and the elegance of design.

Soft robotics is entering a new era—one where machines don’t just move; they remember, adapt, and evolve. And in doing so, they bring technology a little closer to life itself.

More information: Zheyuan Bi et al, Hysteresis-assisted shape morphing for soft continuum robots, Science Advances (2025). DOI: 10.1126/sciadv.adx3024