Every time you walk across a floor, strike a match, or drive your car, you’re encountering one of the most ubiquitous yet underappreciated forces in the universe—friction. It’s an invisible grip that slows us down, keeps us upright, and, paradoxically, makes motion possible. Without it, our feet would slide endlessly across the ground, cars wouldn’t stop, and climbing a hill would be impossible. Yet, too much friction can overheat engines, wear down machinery, and even halt high-speed innovations.

Friction is a fascinating blend of simplicity and complexity, rooted in the ancient laws of mechanics and expanded upon by cutting-edge nanotechnology. This is a force so intuitive that even toddlers feel its effects, yet so intricate that physicists are still uncovering its atomic secrets. In this article, we’ll journey from the basics to the quantum layers of this mysterious resistance, exploring not only what friction is, but why it matters, how it behaves, and where it might take us in the future.

A World in Contact: Understanding Friction’s Origins

Friction, at its core, is a resistance to motion that occurs when two surfaces come into contact. That might seem obvious on a macroscopic scale—like when you push a box across the floor and feel it resist your effort—but the real magic of friction happens at the microscopic and even atomic level.

When two surfaces appear smooth to the naked eye, they’re anything but on closer inspection. If you were to examine them with an electron microscope, you’d find jagged peaks and valleys—microscopic mountains and crevices that define the texture of every material. These surface irregularities interlock when two objects touch, and attempting to move one across the other requires climbing up and over these tiny obstacles. That climbing takes energy. That energy is lost in the form of heat. And that loss is what we call friction.

But even beyond the surface bumps lies a subtler and even more fascinating mechanism: molecular adhesion. When atoms from different materials come close enough, their electrons can interact, forming temporary bonds or exchanging forces. These microscopic grips can be surprisingly strong, especially when the materials are clean, dry, or under high pressure. In fact, in a vacuum with no contaminants, two ultra-flat metal surfaces can fuse together without any glue. That’s atomic-scale friction at its most dramatic.

Static vs. Kinetic: When Stillness is Harder Than Motion

One of the most striking things about friction is that it doesn’t behave the same way when something is stationary versus when it’s already moving. This is the fundamental distinction between static friction and kinetic (or dynamic) friction.

Static friction is the force that resists the initiation of motion. It’s what keeps your parked car from sliding down a gentle slope or your coffee cup from gliding off the dashboard. It’s generally stronger than kinetic friction because it takes more force to get things moving from rest than to keep them moving once they’ve started. This is because at rest, all those micro-interlocking asperities between the surfaces have settled into a sort of equilibrium, maximizing their grip. To break them apart, you need an extra push.

Once motion begins, kinetic friction takes over. This is the force resisting motion as objects slide past each other. While it’s still significant, kinetic friction is usually lower than static friction because the points of contact are constantly breaking and reforming, never fully locking in as they did before movement started. The roughness still causes resistance, and adhesive forces still act, but the surfaces don’t have time to “settle” into each other. This dynamic explains why pushing a heavy object can feel nearly impossible at first and then becomes relatively easier once it starts moving.

The Laws of Friction: From Da Vinci to Amontons

Although friction is a modern field of study in terms of atomic theory and nanotechnology, its principles were observed and recorded long ago. Leonardo da Vinci was among the first to formally study friction in the 15th century, meticulously drawing diagrams and noting empirical rules. But it was Guillaume Amontons in the 17th century who established the classical laws of friction that we still use today in basic physics:

- The force of friction is proportional to the normal force—that is, how hard the two surfaces are being pressed together.

- Friction is independent of the contact area—a counterintuitive but surprisingly accurate observation for many everyday materials.

- Kinetic friction is independent of velocity—at least at low speeds and under ideal conditions.

These laws provide a simple framework that’s still taught in physics classrooms around the world. But like Newtonian gravity, they work best as approximations. They don’t explain everything, especially not at the microscopic or quantum levels, nor do they account for materials that deform, heat up, or chemically interact under stress. Nonetheless, they laid the groundwork for centuries of exploration.

Material Matters: What Surfaces Teach Us

Different materials behave very differently when it comes to friction. Rubber, for example, grips asphalt tightly because of its ability to deform and mold around surface irregularities. Steel on ice, by contrast, offers very little resistance—hence the slipperiness of ice skates. What’s behind these differences?

One key factor is the coefficient of friction—a dimensionless number that represents how much two surfaces resist sliding against each other. It varies widely. Rubber on dry pavement has a high coefficient (around 0.7 or more), while Teflon on steel has a very low one (as low as 0.04). These values are determined by a mix of factors: surface roughness, material elasticity, temperature, and the presence of lubricants.

Interestingly, smoothness doesn’t always reduce friction. Polished metals can sometimes produce more resistance due to increased adhesion. In contrast, rough textures can sometimes reduce friction by trapping lubricants or minimizing actual surface contact through isolated peaks. This duality makes material science a critical field in understanding—and manipulating—friction.

Heat and Wear: The Costs of Resistance

Friction isn’t just about resisting motion—it’s about energy conversion. As two surfaces slide past one another, the kinetic energy used to move them is transformed into heat. This can be both beneficial and destructive. On one hand, frictional heat is what allows matches to ignite or brakes to stop a car. On the other, excessive heat can damage engines, degrade materials, and accelerate wear.

Wear and tear are direct consequences of friction. As surfaces rub together, their microstructures degrade. Small particles are torn off, new grooves are carved, and chemical reactions (like oxidation) may occur. Over time, this leads to reduced performance and eventual failure. Engineers must consider friction when designing everything from ball bearings to spacecraft components, often using lubricants, coatings, or special materials to mitigate its effects.

Lubrication is one of the oldest and most effective strategies for controlling friction. Oils, greases, and even water can create a thin film between surfaces, reducing both adhesion and abrasion. Modern lubricants are highly engineered substances, sometimes containing nanoparticles or synthetic molecules that adapt to pressure and temperature changes. In cutting-edge applications, dry lubricants like graphite or molybdenum disulfide are used where traditional liquids would fail.

From Cars to Cellphones: Friction in Technology

Friction plays a role in nearly every piece of technology we use. In automobiles, it affects how tires grip the road, how brakes slow the vehicle, and how engines dissipate heat. Too much friction can cause overheating and inefficiency; too little can lead to slippage and loss of control. Automotive engineers constantly walk a tightrope between these extremes.

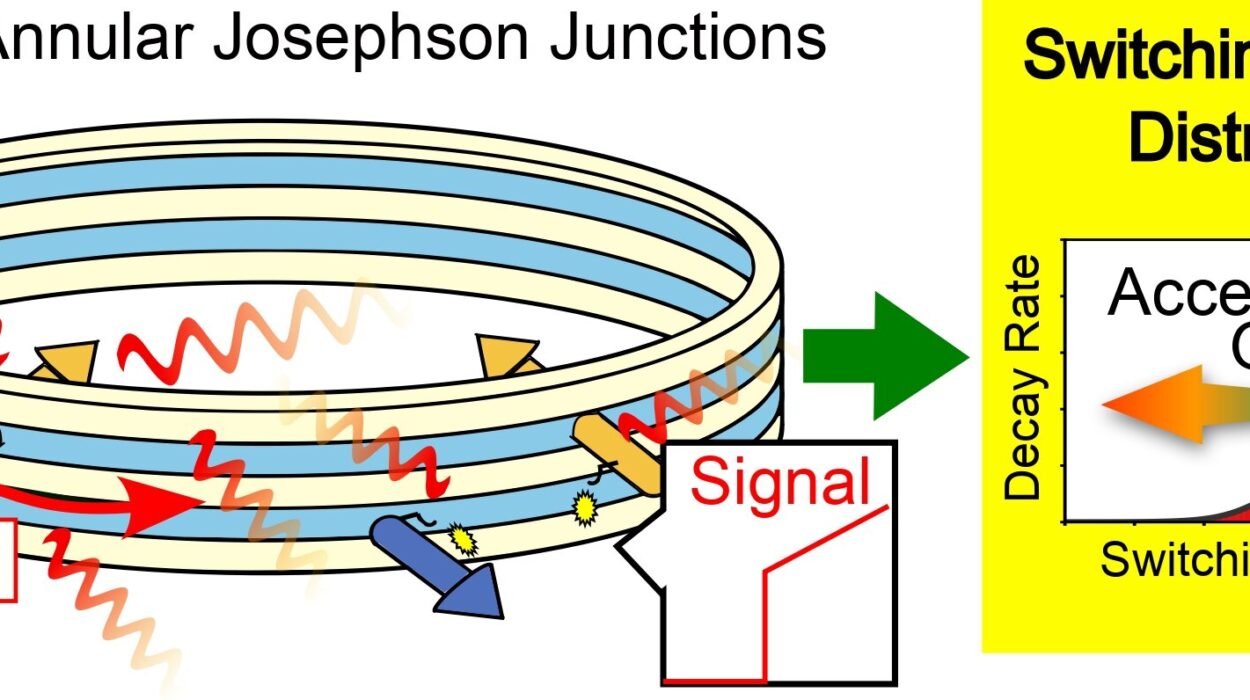

In electronics, friction is no less important. Microelectromechanical systems (MEMS)—tiny machines used in phones, sensors, and medical devices—face unique challenges because at small scales, surface forces like friction and adhesion dominate over inertia. Engineers must carefully design these systems to minimize stiction (a kind of sticky friction that keeps parts from moving) and wear.

Even in computing, friction rears its head. Hard drives, for instance, contain spinning disks and read/write heads that hover nanometers apart. A small increase in friction could mean data loss. In modern laptops, fans and moving parts must balance frictional resistance against cooling needs. And in the futuristic world of quantum computing, friction could introduce noise and error—meaning the quest to understand it is more relevant than ever.

Friction at the Atomic Level: Welcome to Nanotribology

The classical picture of friction—blocks sliding across planes, roughness creating resistance—begins to break down at atomic scales. Here, the new field of nanotribology takes over. It explores friction, wear, and adhesion between tiny structures, down to the level of individual atoms and molecules.

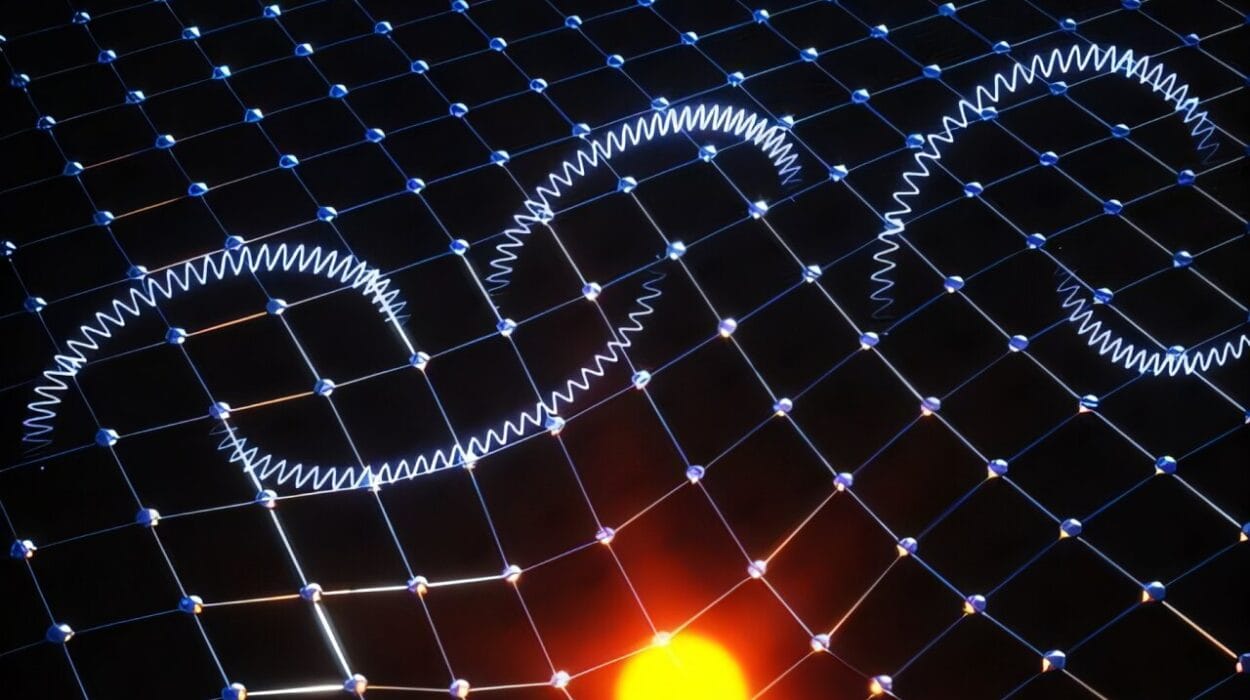

Atomic force microscopes (AFMs) allow scientists to measure friction with extraordinary precision. These instruments use a needle-sharp tip dragged across a surface, detecting the forces involved at the nano- or even piconewton scale. What researchers have found is both fascinating and puzzling. Friction doesn’t always follow classical laws. Sometimes, surfaces slide almost frictionlessly—a phenomenon known as superlubricity.

Superlubricity occurs when two crystalline surfaces are incommensurate—meaning their atomic structures don’t align. This misalignment prevents the usual sticking and slipping that generates friction. Experiments have achieved near-zero friction with graphene sheets, molybdenum disulfide layers, and other nanostructures. If harnessed, superlubricity could revolutionize machines, reducing energy loss and wear to nearly zero.

The Future of Friction: Designing Resistance

As we look forward, the science of friction promises new innovations and deeper understanding. Smart materials that adapt their frictional properties on demand could make machines more efficient and adaptable. Self-lubricating surfaces might eliminate the need for oils and greases. And at the quantum level, new discoveries may eventually rewrite our understanding of motion itself.

There’s also growing interest in bio-inspired friction. Nature has evolved brilliant solutions to frictional challenges: geckos with adhesive feet, snakes with friction-reducing scales, and human joints with ultra-low-friction cartilage. Engineers and material scientists are learning from these natural systems to create artificial surfaces that mimic their properties.

Friction also intersects with sustainability. In an age of climate crisis, reducing friction in engines, turbines, and industrial systems could significantly cut energy consumption. Even tiny gains in efficiency—multiplied across billions of machines—could have massive environmental impacts.

Conclusion: A Force Both Friend and Foe

Friction is an inescapable part of our physical world. It’s what lets us walk without slipping, drive without skidding, and stop without crashing. Yet it’s also what causes tires to wear out, machines to break down, and energy to be lost. It is both a friend and a foe, a helper and a hindrance.

Understanding the physics of friction isn’t just an academic exercise—it’s a practical necessity. From everyday tools to cosmic machinery, from ancient levers to quantum nanotechnology, friction shapes the way things move and how energy flows. As our mastery of matter grows ever more refined, our control over this invisible force will continue to evolve, opening new possibilities for motion, power, and design.

Friction may resist motion, but it will never stop our pursuit of knowledge.